5-34 BA 50Z3/6003 en – Edition 4.3 * * 5003b530.fm

Maintenance

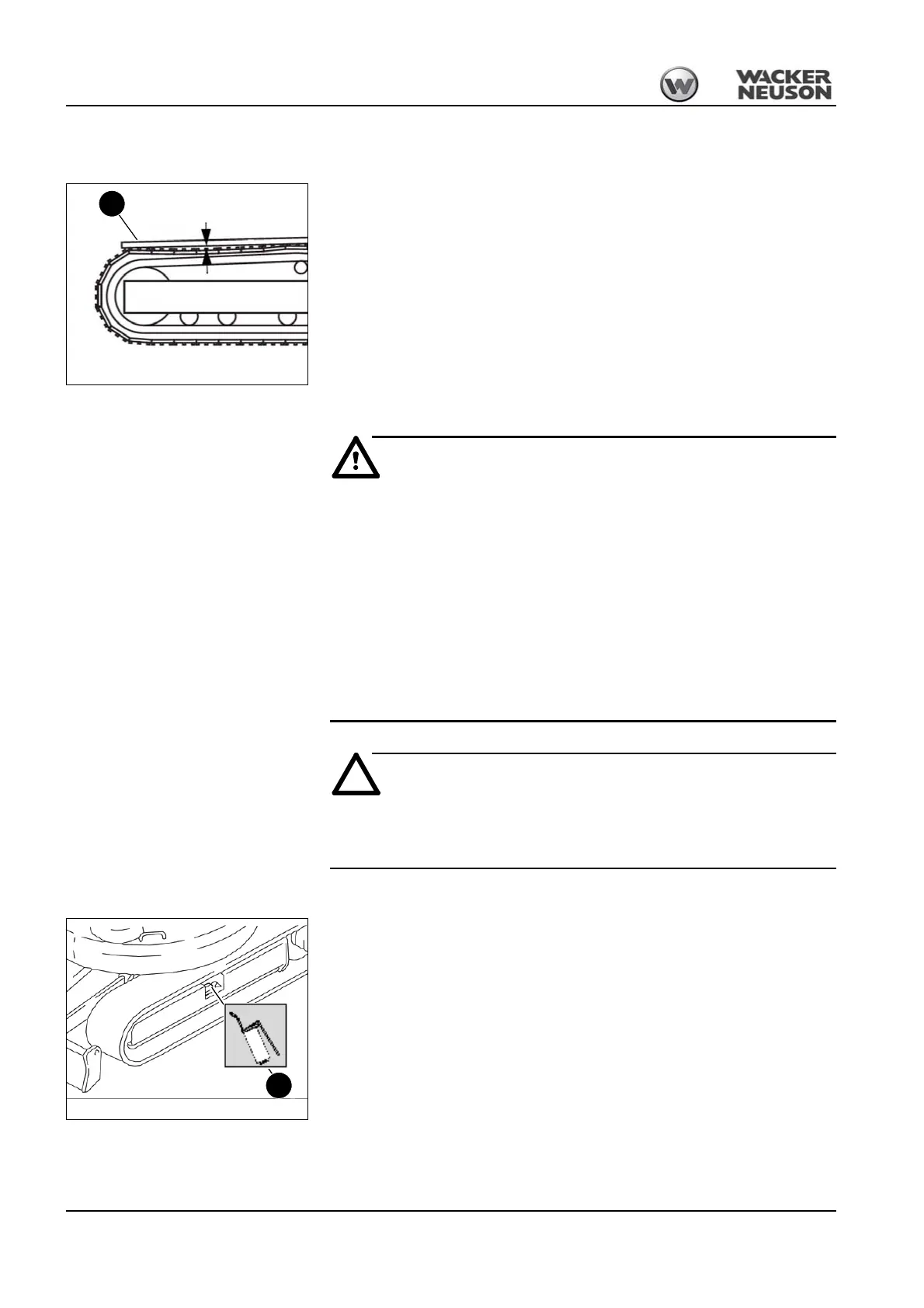

Checking the track tension of the steel tracks (option) and hybrid tracks (option)

☞ Place the machine on firm, level and horizontal ground.

☞ Stop the engine.

☞ Raise the control lever base.

☞ Remove the ignition key and carry it with you.

☞ Use suitable auxiliary means to support the machine.

☞ Place a measuring rod A across the highest points of the track.

➥ The track must sag 20 – 30 mm (0.78 – 1.81 in) in the middle.

☞ Set the tension as follows if it is not in accordance with the rated value – see Adjust-

ing track tension on page 5-34.

Adjusting track tension

The lubricating valve can be squeezed out due to the high grease pressure in

the hydraulic ram.

Risk of injury.

☞ Open the lubricating valve only very carefully and do not slacken it more

than a revolution.

☞ Slacken no other component except the lubricating valve.

☞ Keep your face away from the lubricating valve connection.

➥ Contact an authorized workshop if this does not reduce track tension.

☞ Release grease only as described below.

☞ Observe the safety instructions.

Excessive tension of the tracks causes severe damage to the ram and the

track.

☞ Tighten the tracks only up to the prescribed measuring distance.

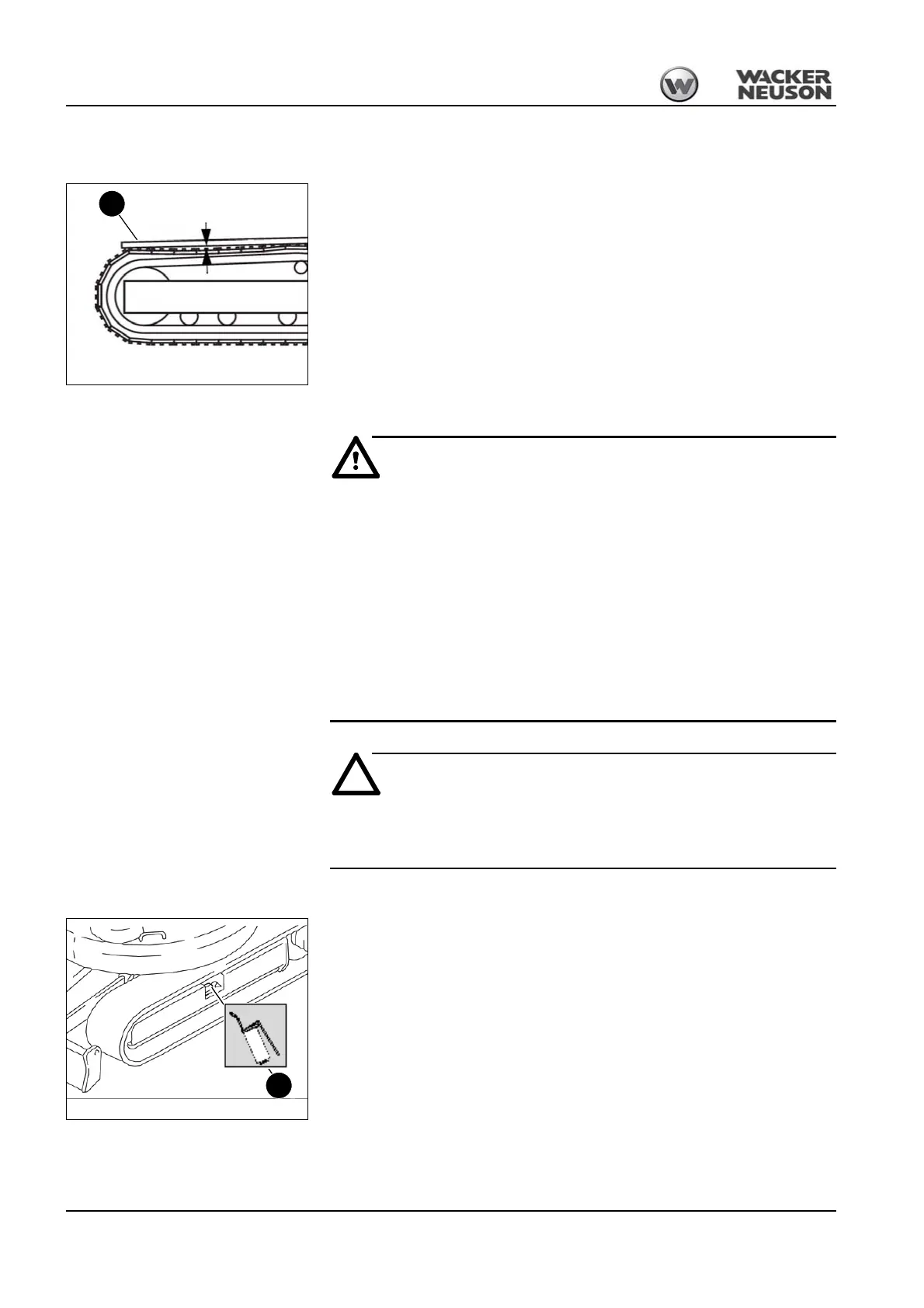

Tightening the tracks

☞ Inject grease with the pump through lubricating valve A.

☞ Check the tension is correct by lowering the machine to the ground, starting the engine,

letting it run at idling speed without any load and slowly moving the machine forward

and reverse and switching it off again.

☞ Check the tension of the tracks again.

➥ If the tension is not correct:

☞ Adjust again.

☞ Should the tracks still be slack after injecting more grease, replace the tracks or the

seals in the rams. Contact an authorized workshop in this case.

Fig. 297: Measuring distance

A

20 – 30 mm (0.78 – 1.81 in)

Fig. 298: Tightening the tracks

A

Loading...

Loading...