Marine Installation Manual 2022-03 4-31

4 Ancillary Systems

4.4 Lubricating oil systems

X62DF-S2.0

Cylinder LO trace

heating cable

WinGD specifies the 10QTVR2-CT self-regulating heating cable for engine in-

ternal and external cylinder LO piping. Detailed technical information about this

cable can be found in MIDS.

To reach the required LO temperature of 40 +10/-5°C, the proper length of

heating cable must be selected for the engine and traced along the system side

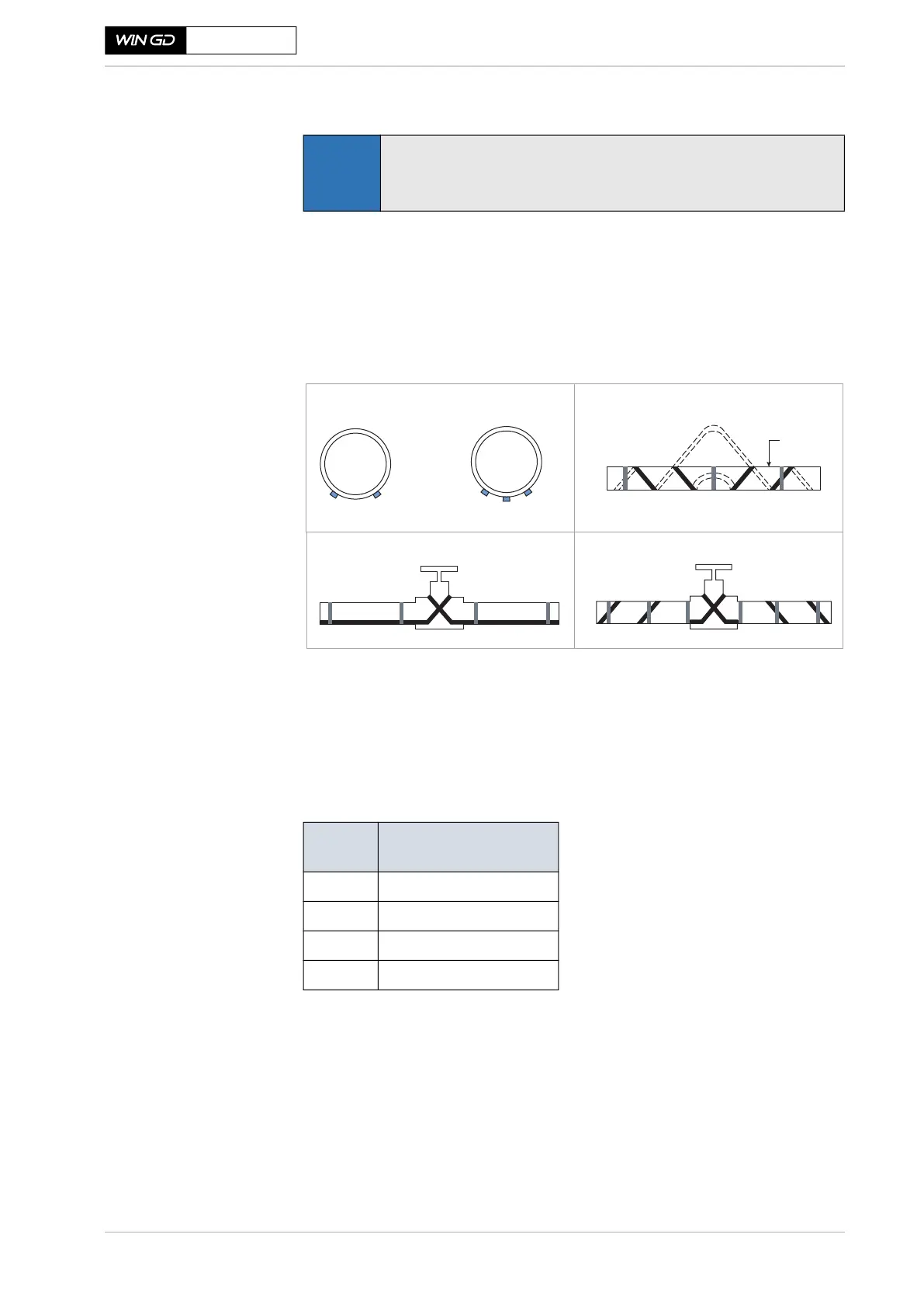

piping spirally or in parallel, depending on the cable/pipe ratio (see Figure 4-19).

Figure 4-19 Trace heating cable arrangement

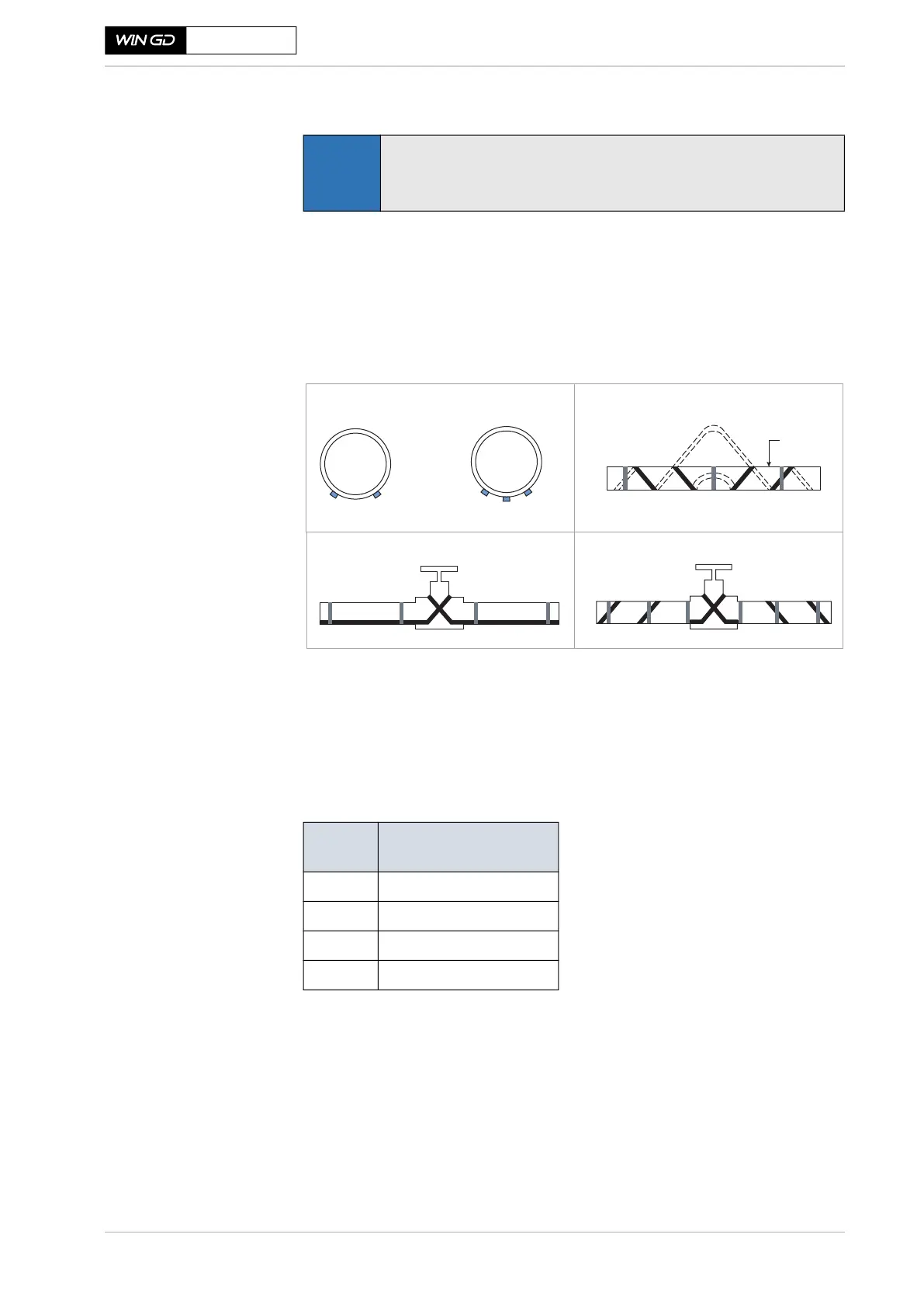

Considering the ME power, LO feed rate and environment condition, WinGD

specifies a minimum heating cable length ‘Lc’ as listed in the following table:

Table 4-3 Heating cable specification

Considering the system side cylinder LO pipe length ‘Lp’, the heating cable must

be longer than the lubricating oil pipe, i.e. ‘Lc’ > ‘Lp’.

Insulation of trace heated

cylinder LO pipe

To maintain the desired temperature, the system side cylinder LO pipe must be

well insulated. The following requirements must be considered:

• Insulation material such as mineral wool, glass fibre, or other material of

class approved type can be applied.

• WinGD recommends an insulation thickness of minimum 25mm.

NOTE

On the engine side, electrical trace heating is applied in the rail unit to

keep the cylinder lubricating oil within the required temperature range,

even during gas operation in cold areas.

No. of

cyl.

Min. heating cable length

‘Lc’ [m]

5 10

6 11

7 13

8 15

Pipe

Straight line pipe heating cable installation

Double parallel

heating cable

N = 2 N = 3 or more

N = 3 or more

Multiple parallel

heating cable

Spiral wrap pipe heating cable installation

Multiple spiral heating cable

Loading...

Loading...