Marine Installation Manual 2022-03 4-73

4 Ancillary Systems

4.7 Fuel oil system

X62DF-S2.0

Viscometer

The viscometer regulates the fuel oil end-heater, enabling the fuel oil viscosity to

be kept at preferable engine conditions. When using HFO/LSHFO the ideal is

13-17cSt, and between 10-20cSt is acceptable. Although there is no active

cooling required to keep the minimum limit of 10 cSt, the absolute minimum vis-

cosity is 2cSt.

When using low-viscosity fuels, the end-heater must not be active and the

MDO/MGO heat exchangers will be required to maintain these limits.

MDO/MGO heat exchanger

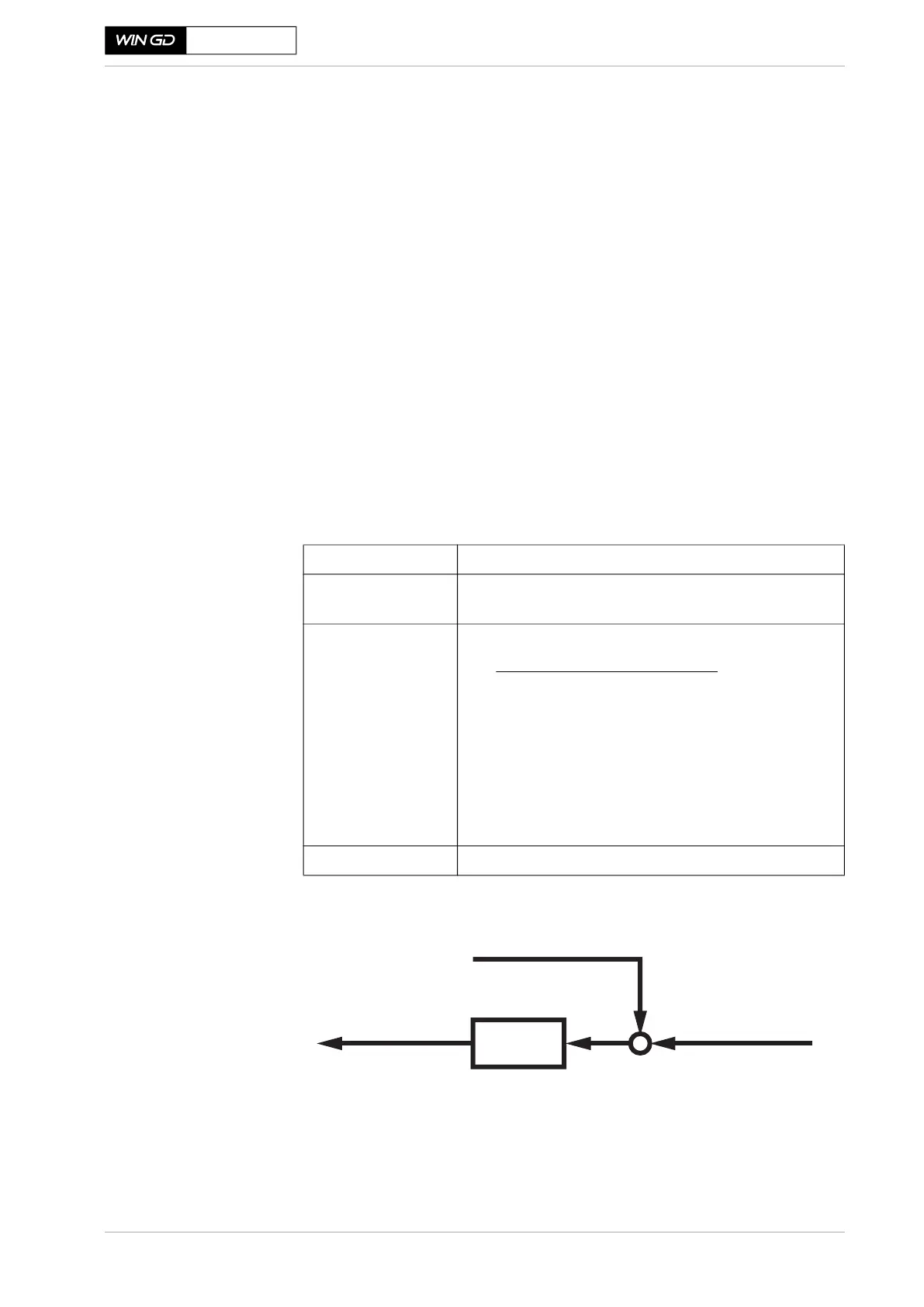

For MDO/MGO operation, the fuel might need to be cooled to stay above a

minimum viscosity of 2 cSt at engine inlet. This fuel oil heat exchanger (and any

optional heat exchanger that is included, as shown in Concept Guidance Distillate

Fuels) uses low-temperature cooling water.

A chiller unit (cooling from refrigeration) is not required if the fuel properties are

in line with the latest ISO 8217:2017 specification. Such a unit would only be

needed for off-spec fuels that are not supported by WinGD.

Type Tubular or plate type heat exchanger, suitable for diesel oils

Cooling medium LT cooling water

Alternatively: glycol-water mixture delivered from chiller unit

Cooling capacity [kW]

where:

Q [kW]

BSFC [g/kWh]

P [kW]

T

1

[°C]

T

2

[°C]

= cooler heat dissipation at 100 % engine load

= specific fuel consumption at design conditions

and 100% engine load

= engine power at 100% CMCR

= temp. of distillate fuel supplied to engine

= temp. of distillate fuel required at engine inlet

Working pressure Max. 12bar, pulsating on fuel oil side

0.34 25.65

SM-0187

From the engine

Distillate fuel supplyTo the engine T

1

T

2

MDO/MGO

heat exchanger

Loading...

Loading...