Marine Installation Manual 2022-03 1-11

1 Engine Summary

1.3 Fuel operating modes

X62DF-S2.0

Shaft power meter requirements

For all WinGD X-DF engines, the ECS requires the installation of a power meter

in the shaft line. This is to measure required parameters (see Table 1-7). The po-

sition of the shaft power meter is usually as close as possible to the main engine’s

flywheel. In the case of a PTO/PTI/PTH installation on the driving end side,

this means that the shaft power meter is usually installed between the PTO/PTI/

PTH and the main engine’s flywheel (see Figure 4-68, 4-114). Alternatively,

the mechanical power of the PTO must be calculated and transferred to the ECS

through the Propulsion Control System (PCS). This enables the ECS to deter-

mine the total mechanical power output of the engine, which is required for the

engine operation (see Figure 5-1, 5-1). The same calculation method must be

applied to a PTO installation on the free end side.

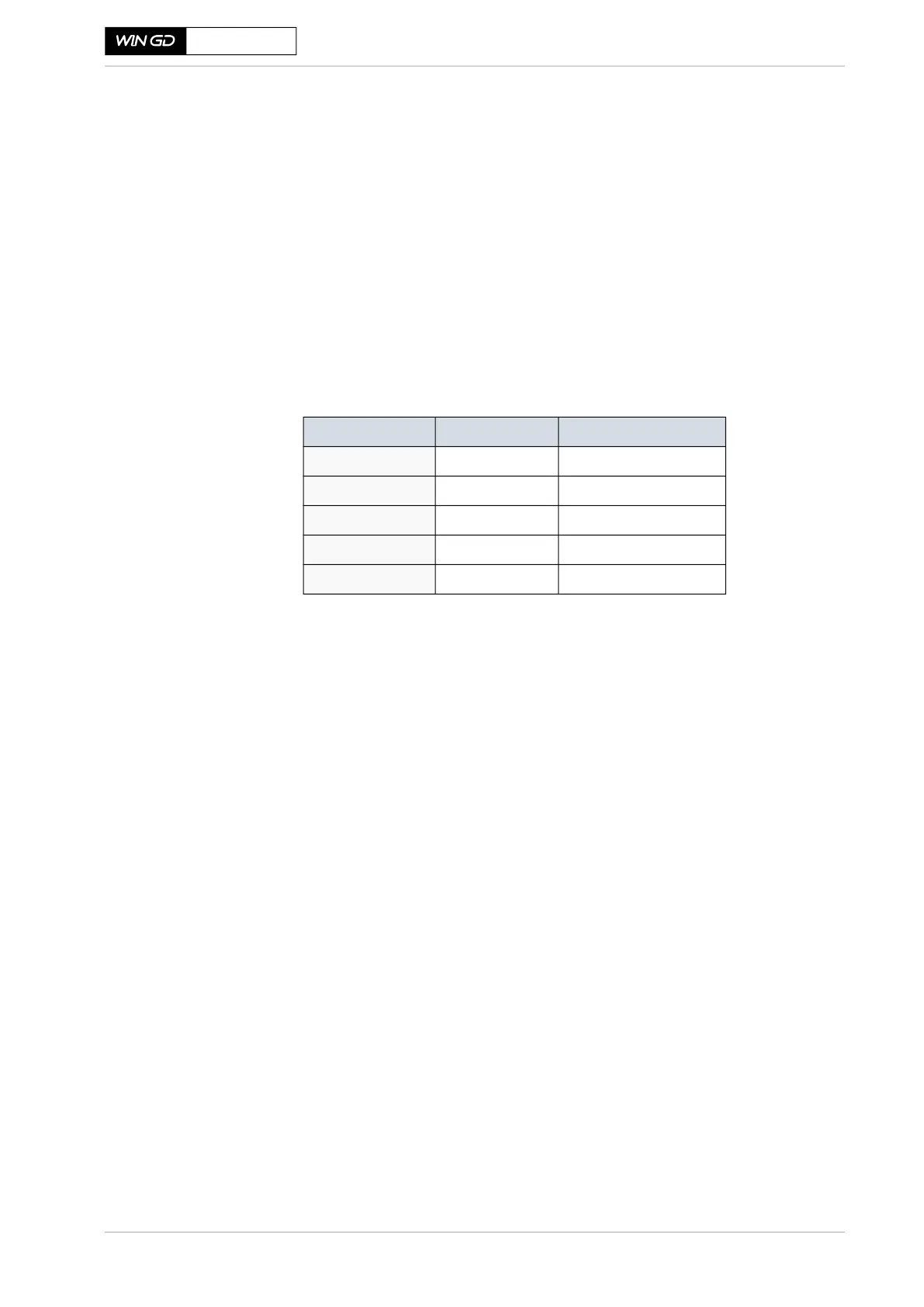

Table 1-7 Shaft power meter parameters

The iCER system

As part of the X-DF2.0 technology, this engine is equipped with the Intelligent

Control by Exhaust Recycling (iCER) system. While in gas mode, this allows for

the recirculation of part of the exhaust gas back to the engine. This replaces the

oxygen in the scavenge air inlet with CO

2

, resulting in an enhanced combustion

process.

The iCER system offers the following customer benefits:

• Reduced methane slip by up to 50 %

• Reduced energy consumption in gas mode

• Improved fuel consumption in diesel mode

Figure 1-6, 1-12 provides a schematic of the iCER system with one turbo-

charger.

Abbreviation Value Parameter

A ±0.5 % Sensor accuracy

U ≤1.0 s Update rate

D ≤0.5 s Delay

S ≥10 Hz Sampling rate

ES 4-20 mA Electrical signal

Loading...

Loading...