Marine Installation Manual 2022-03 4-98

4 Ancillary Systems

4.9 Leakage collection system and washing devices

X62DF-S2.0

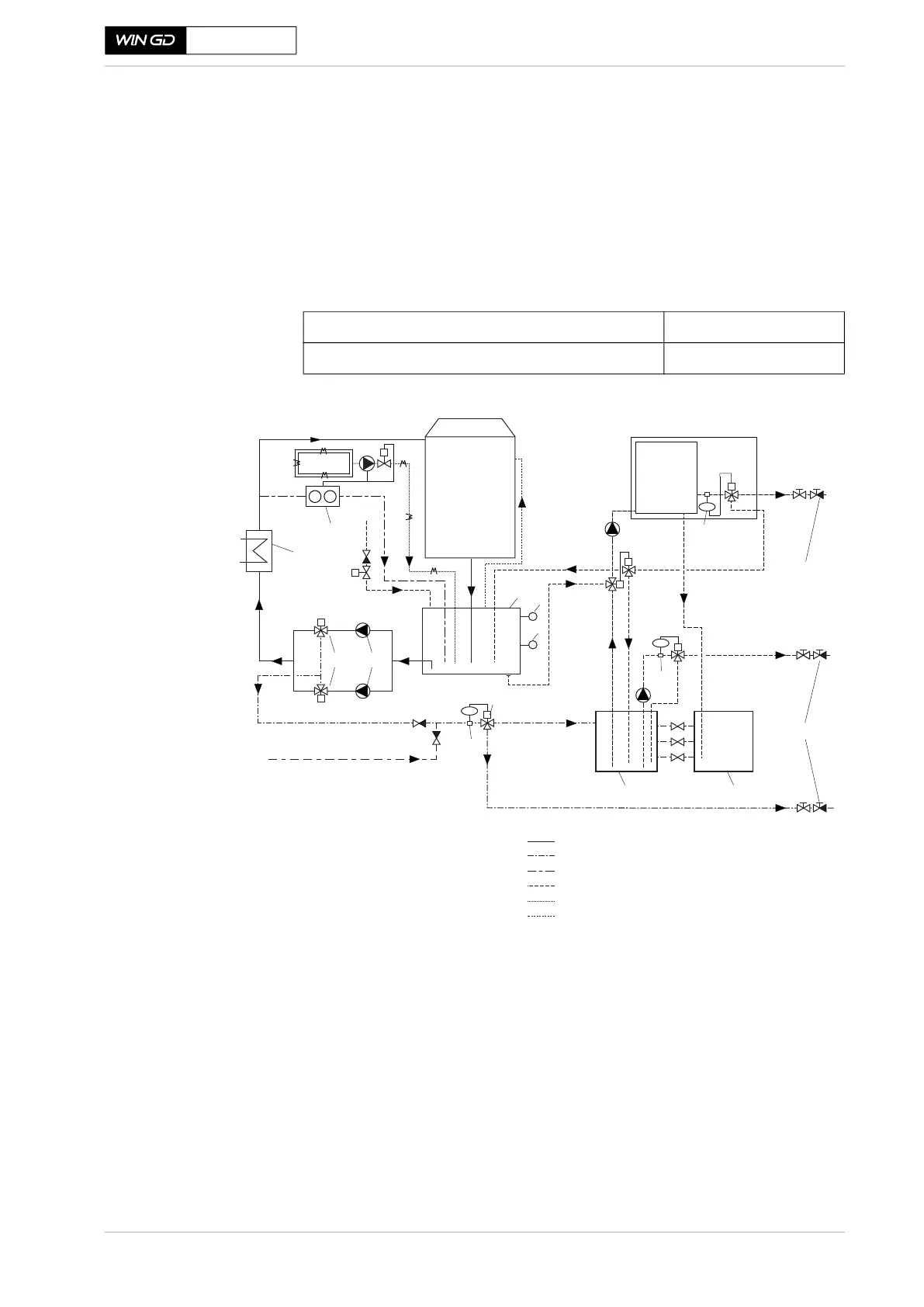

If the oil-in-water content in the EGC drain tank exceeds 15 ppm, oil removal by

means of a water treatment unit is then required. Otherwise, if the oil-in-water

content of the water in the EGC drain tank does not exceed 15 ppm and the

vessel is operating outside an area of restricted overboard discharge, the water

can then be directly pumped overboard. Figure 4-58 provides a sketch of the

iCER drainage system for installations with gas and diesel Tier III mode opera-

tion.

Chemical consumption

during diesel Tier III

mode operation

Table 4-15 Chemicals required for treatment of the EGC circulation water

Figure 4-58 The iCER drainage system for installations with gas and diesel Tier III

mode operation

Alternatively, an iCER drainage system with two separate water treatment units

can be considered. One unit handles the bleed-off water and the SAC drain water

(during iCER operation), the other handles the EGC circulation water as shown

in Figure 4-59, 4-99.

Coagulant consumption (if applicable): According to supplier

Caustic soda (50% m/m NaOH) consumption: 0.2 l/MWh

SM-0695

o/w

o/w

EGC

Separator

Coagulant

Dosing

pump

NaOH

pH QC

LT

LSH

1

2

3

Overboard

6a

1 EGC circulation water cooler

2 EGC circulation water pumps

(frequency controlled)

3 EGC circulation water tank

4 EGC drain tank

5 EGC sludge tank

6 Oil-in-water monitoring sensor:

6a UV type

6b Standard type

7 Bleed-off valves

8 Water analyser (pH and quality)

9 Level transmitter

10 High-level switch

EGC circulation water system

Bleed-off system

Water sampling line

Water treatment system

pH-neutralisation dosing unit

Venting pipes

with manual

override

7

o/w

6a

6b

4

5

Fresh water

refill

8

Overboard

from SAC drain during

iCER operation

9

10

o/w

Water

treatment

unit

6b

Loading...

Loading...