BASIC USES OF Σ-SERIES PRODUCTS

2.4.5 Minimum User Constants Required and Input Signals

48

2.4.5 Minimum User Constants Required and Input Signals

1) This section describes the minimum user constants that must be set to conduct a test run.

For details on how to set each user constant, refer to 4.1.5 Operation in User Constant

Setting Mode.

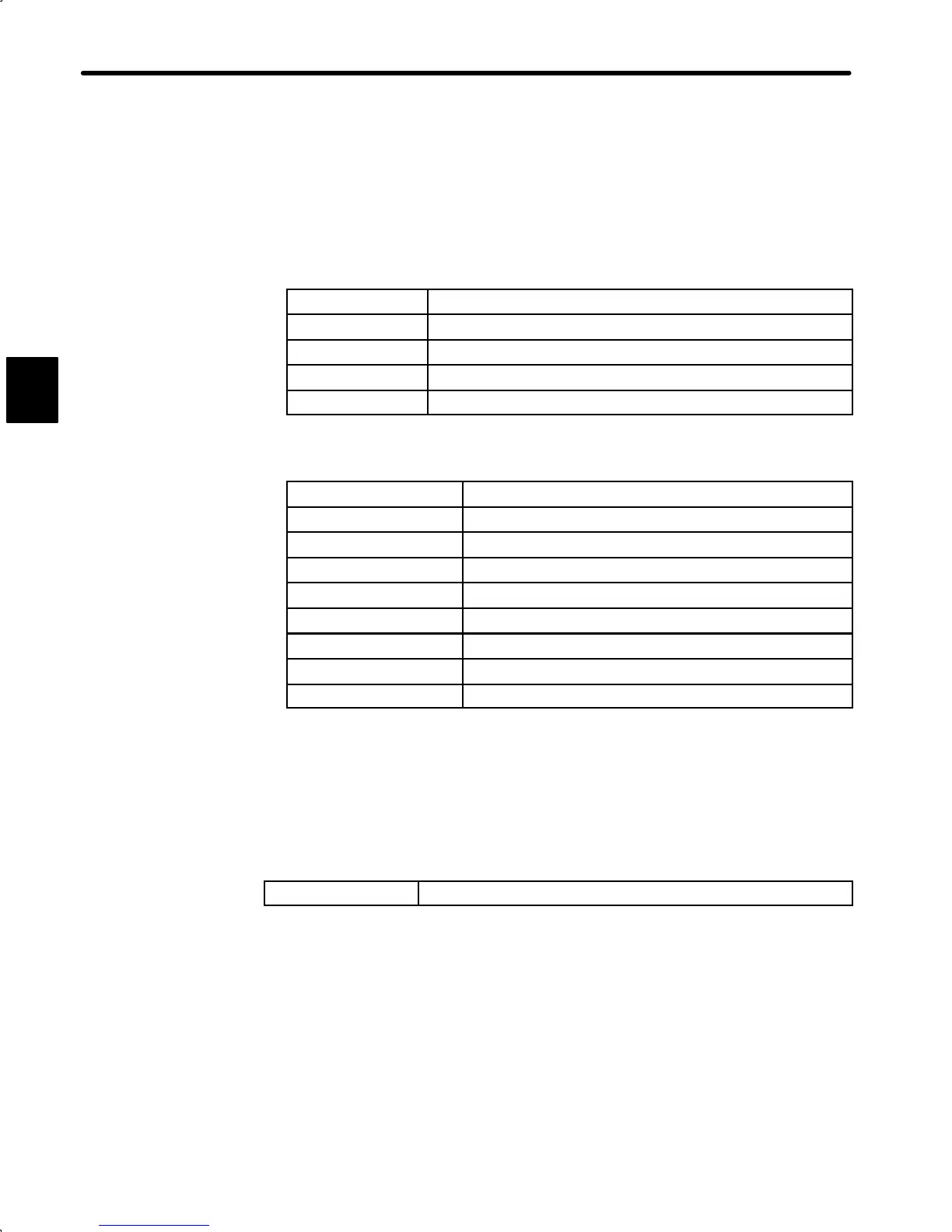

a) Servopack for speed/torque control

Cn-01 bit E

Encoder selection

Cn-02 bit 8 Motor selection

Cn-03 Speed reference adjustment gain

Cn-0A Encoder pulse dividing ratio

Cn-11 Number of encoder pulse

b) Servopack for position control

Cn-01 bit E

Encoder selection

Cn-02 bit 8 Motor selection

Cn-02 bits 3,4,5 Reference pulse form selection

Cn-02 bit D Logic of reference pulse

Cn-02 bit F Reference pulse output form

Cn-0A Encoder pulse dividing ratio

Cn-11 Number of encoder pulses

Cn-24 Electronic gear ratio (numerator)

Cn-25 Electronic gear ratio (denominator)

After changing the Cn-02 setting, always turn the power OFF, then ON. This makes

the new setting valid.

alone

2) If the specified direction of rotation differs from the actual direction of rotation, the wiring

may be incorrect. In this case, recheck the wiring and correct it accordingly. Then, if the

direction of rotation is to be reversed, set the following user constant:

Cn-02 (bit 0)

Reverse rotation mode (see page 54)

After changing the Cn-02 setting, always turn the power OFF, then ON. This makes the

new setting valid.

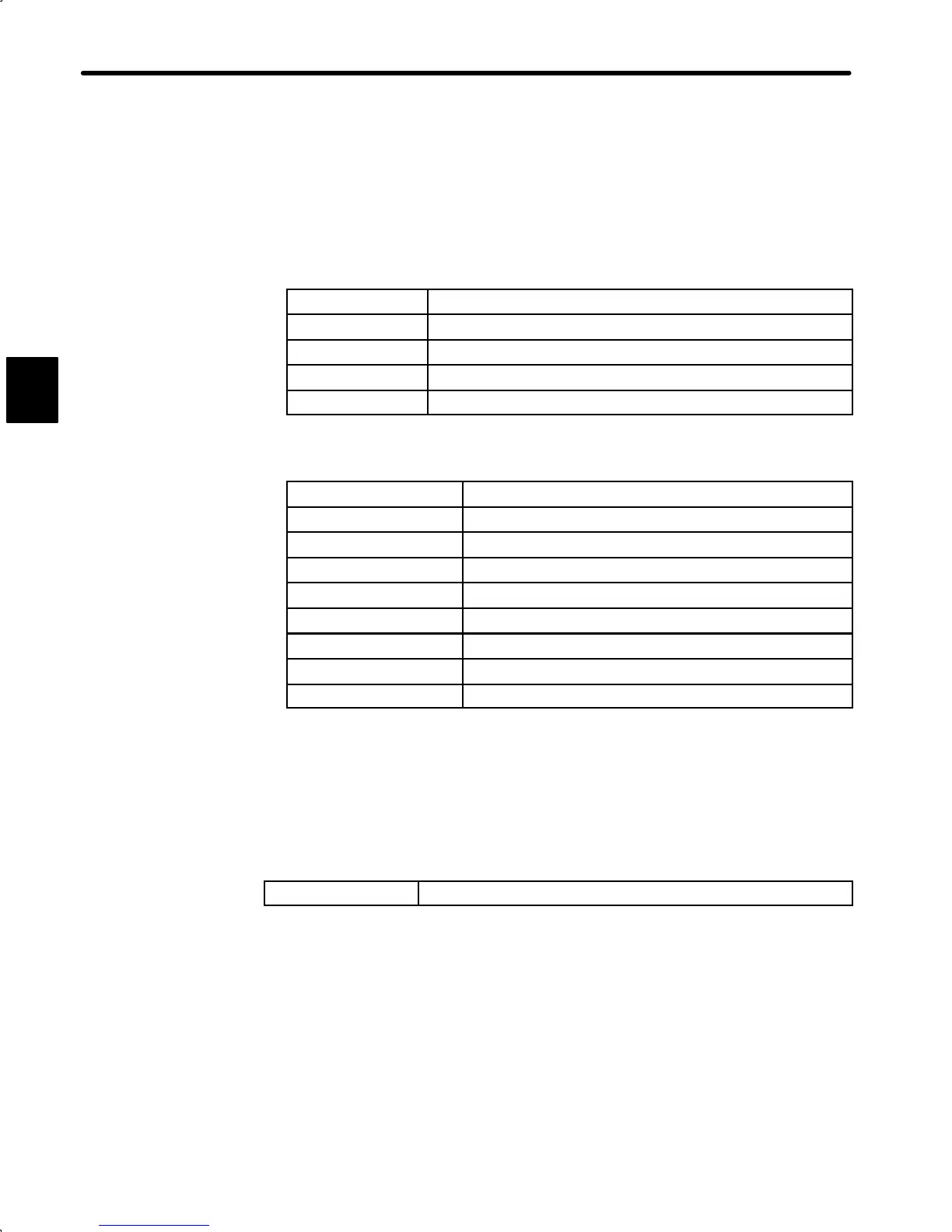

3) The following table lists the minimum input signals required to conduct a test run. For de-

tails of each input signal, refer to the relevant page.

2

Loading...

Loading...