<11. Inspection and Maintenance>

11-6

IM 11M12A01-04E 11th Edition : Jul. 19, 2017-00

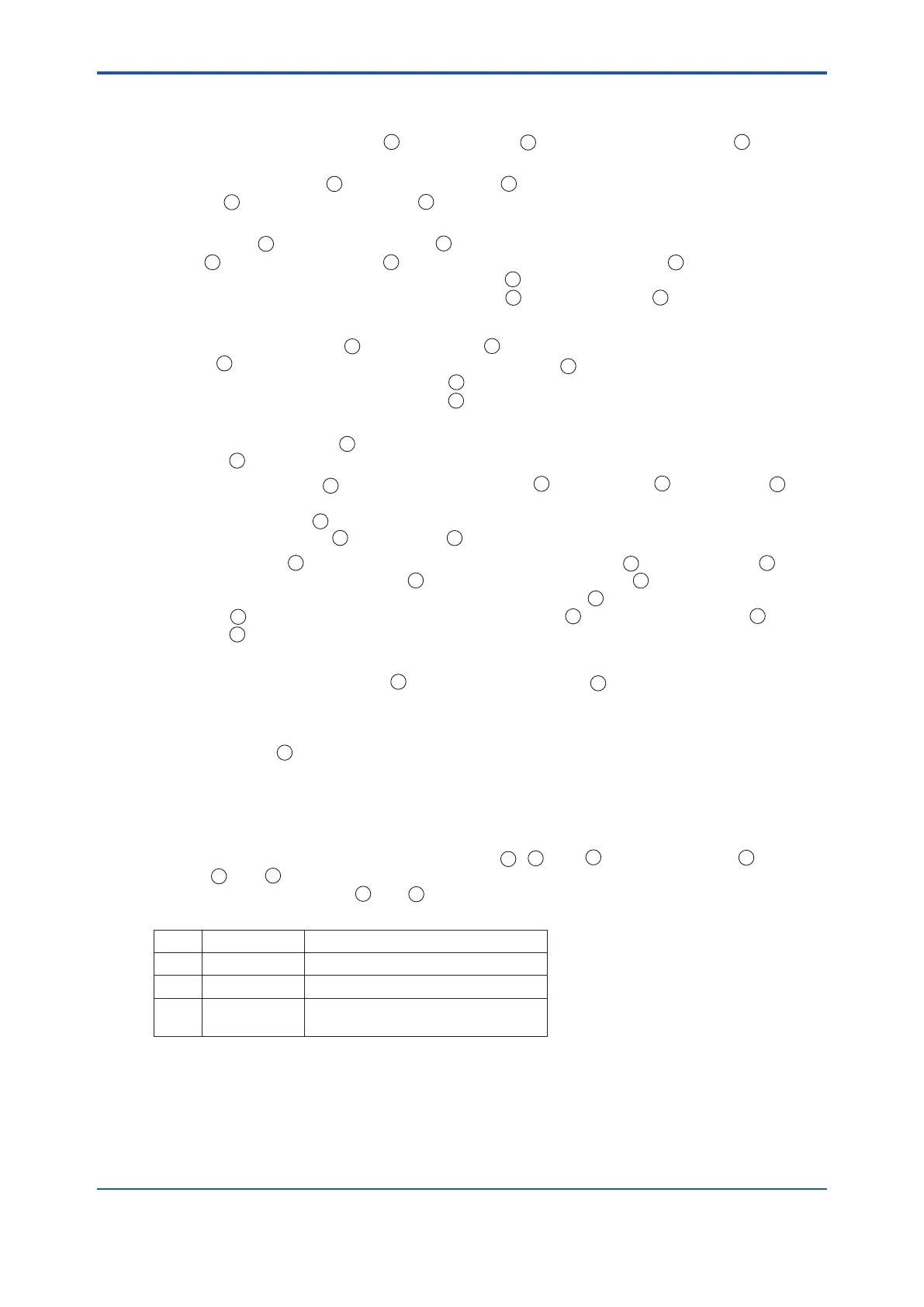

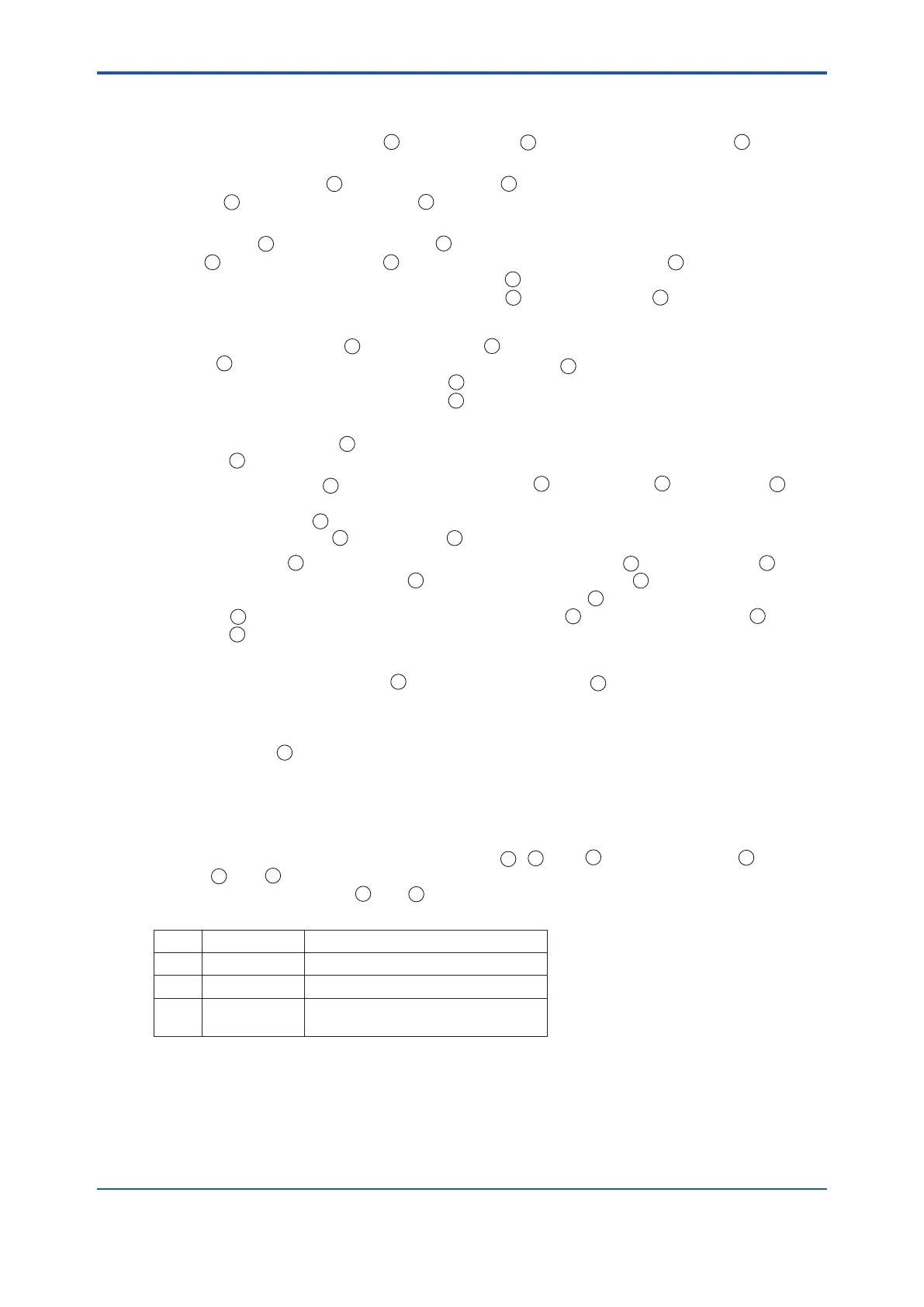

Replacement of heater assembly

Refer to Figure 11.4 as an aid in the following discussion.

Remove U-shaped pipe support

4

, U-shaped pipe

5

, Filter and the sensor (cell)

6

, following

Section 11.1.2, earlier in this manual.

Remove the two screws

15

that tighten the cover

12

and slide it to the ange side. Remove the

four bolts

10

to remove the converter

16

. Then remove the three connectors to which leadwire

from the heater and thermocouple is connected.

Loosen screw

19

until heater assembly

23

plate can be removed. There’s no need to remove

O-ring

18

which prevents screw

19

from dropping out. Pull out connector

13

. Loosen and

remove the screw for the heater assembly xation

8

with a special wrench (part no. K9470BX or

equivalent) and then remove the heater assembly

23

from the detector

24

.

To reassemble the heater assembly, reverse the above procedure:

Insert the heater assembly

23

into the detector

24

, while inserting the calibration pipe in the

detector

24

into the heater section in the heater assembly

23

as well as in the bracket hole. Coat

the screw for the heater assembly xation

8

with grease (Never-Seez: G7067ZA) and tighten

the screw for the heater assembly xation

8

with a special tool (part no. K9470BX or equivalent)

with a tightening torque of 12N·m ± 10%.

Next, to install the O-rings

22

on the calibration-gas and reference-gas pipes, disassemble the

connector

13

in the following procedure:

First, remove the screw

25

and then remove the plate

17

and two caps

20

. If the O-ring

22

remains in the hole, pull them out from the back. Pass the heater and thermocouple leadwire

through the connector

13

. Also, pass the calibration gas and reference gas pipes through the

opening of the connector

13

. If the O-ring

22

fails, replace it with a new one.

Push the two caps

20

into the associated opening of the connector

13

. Insert the plate

17

,

aligning it with the groove of the cap

20

, and tighten it with the screw

25

. If you attempt to insert

the calibration gas and reference gas pipes into the connector

13

without disassembling the

connector

13

, the O-ring may be damaged. Tighten screw

19

in the heater assembly

23

until

connector

13

can’t move.

Reassemble in reverse order to the above disassembly procedure.

When installing the cell assembly

6

, replace the metal O-ring

7

with a new one.

11.1.4 Replacement of Dust Filter

Set the dust lter

1

in place using a special pin spanner (with a pin 4.5 mm in diameter: part no.

K9471UX or equivalent). If a dust lter that has already been replaced once is used again, apply

grease (Never-Seez: G7067ZA) to the threads of the dust lter.

11.1.5 Replacement of O-ring

The detector uses three different types of O-rings

14

,

24

, and

22

. One O-ring alone

14

, or two

O-rings

21

and

22

are used. (For a pressure compensating model, two O-rings are used for

individual uses. Two O-rings

21

and

22

are used for reference gas sealing and require periodic

replacement.

Part No. Description

(7) K9470BJ Metal O-ring

(14) K9470ZS O-ring with grease

(21)

(22)

K9470ZP Two pairs of O-rings with grease

Loading...

Loading...