13

Configuring ACS355 drives

Starting ACS355 drives for PROFIBUS DP

1. Power up the drive.

2. Enable the communication between the adapter module and the drive by setting parameter 98.02

COMM PROT SEL to EXT FBA.

3. Set the FPBA-01 configuration parameters in group 51. At the minimum, set the required node

address in parameter 51.02 and the communication profile in 51.05 = 1 (ABB drives).

4. With parameter 30.18 COMM FAULT FUNC, select how the drive reacts to a fieldbus communication

break.

5. With parameter 30.19 COMM FAULT TIME, define the time between communication break detection

and the selected action.

6. Define the process data transferred to and from the drive in the FBA-01 configuration parameter

groups 54 and 55.

Note: The adapter module sets the Status word and actual value automatically in parameters 54.01

and 54.02, and Control word and reference in parameters 55.01 and 55.02.

7. Validate the settings made in parameter groups 51, 54 and 55 by setting parameter 51.27 FBA PAR

REFRESH to REFRESH.

8. Set the relevant drive control parameters to control the drive according to the application.

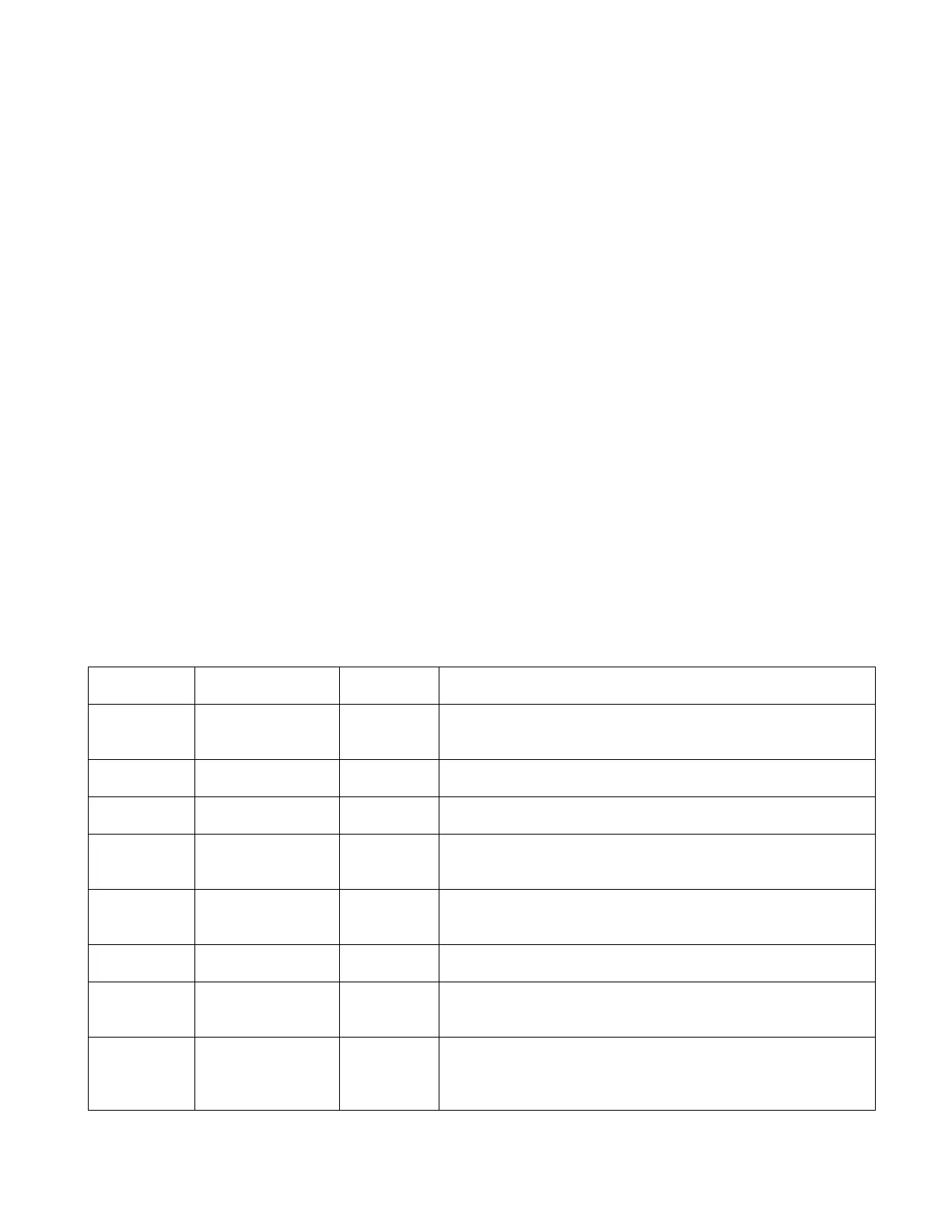

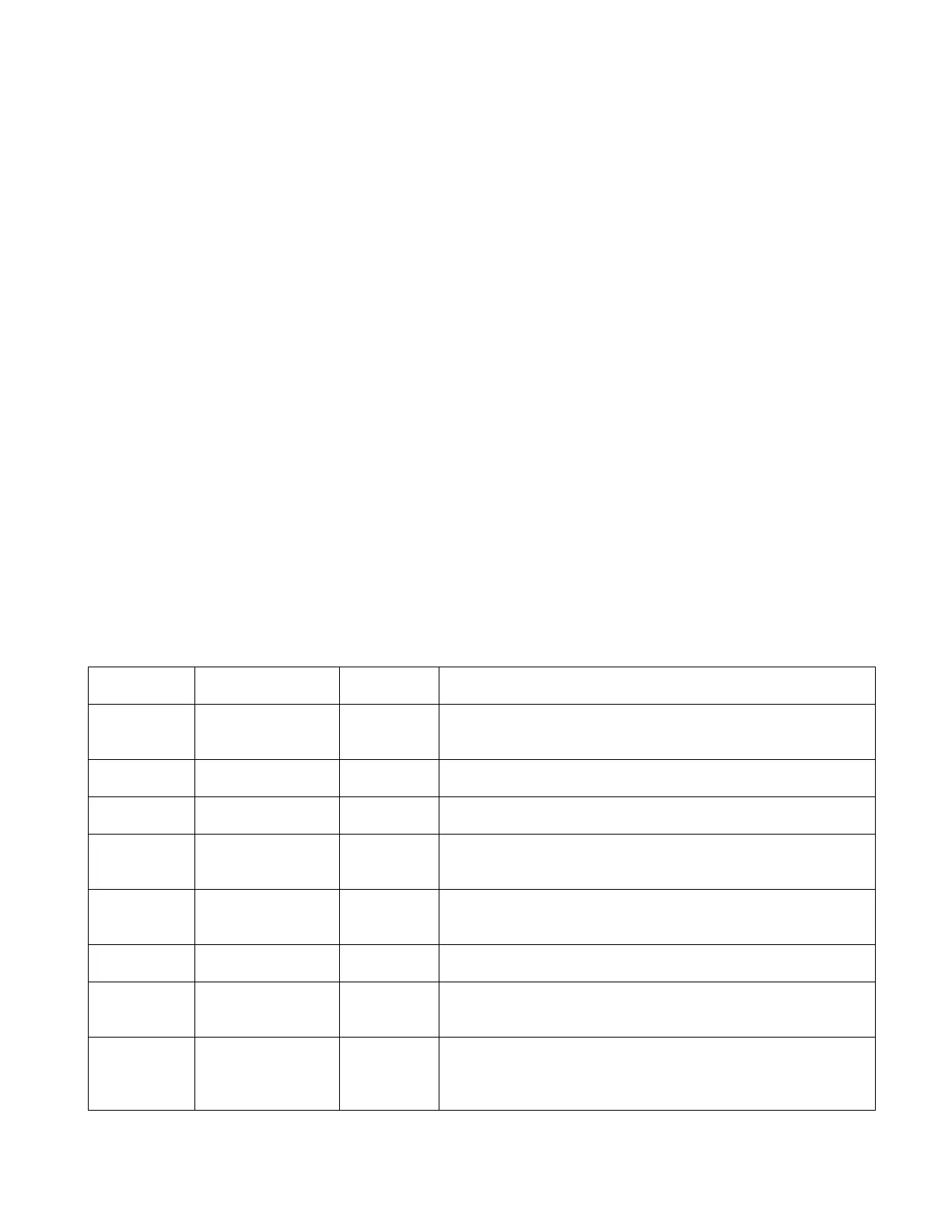

ACS355 Minimum required parameter settings for PROFIBUS DP

The minimum required parameter settings are based on factory default settings.

Activates fieldbus module.

PROFIBUS DP node address of the drive.

Communication profile ABB drives.

Updates fieldbus settings (groups 51 to 55).

Fieldbus interface as source for start and stop.

Fieldbus interface as source for speed reference.

Fieldbus interface as source for fault reset.

Max speed/frequency scaling value (used in function

block/visualization input SPEED_REF_MAX). Must be less

or equal to drive parameter max speed/frequency.

Loading...

Loading...