HEALTH & SAFETY

1-10 L025317 Issue 1 March 2011

Materials

All guard materials must be opaque to 9 to 11 micron wavelength laser light

produced by the CO

2

laser. Guards may be metallic, however if a see-through

guard is required, acrylic (perspex or flexiglass) or polycarbonate may be used.

The thickness of the guard material depends on the mechanical strength

required, and the amount of ‘burn through’ anticipated. For the purpose of

adequate mechanical rigidity, a thickness of at least five millimetres, and

preferably eight millimetres is recommended.

A ceramic or metal plate may be used as a beam stop. A greater thickness is

required to achieve eight hour burn through requirement.

Guidance regarding laser guards can be found in EN60825-Part 4.

Interlock Switches

Interlock switches must be fitted to all access guards preventing access to the

laser output lens and marking area that can be opened without the use of

access tools.

Interlock switches must be wired into the laser control circuit so that the laser

beam is disabled when the guard is removed.

Guarding Labels

Domino recommend that the following information is prominently displayed

on the guard:

Class 4 laser is enclosed in a Class 1 enclosure. Operation of the

system with safety guards removed may result in hazardous exposure

to laser radiation.

These labels are supplied with the laser system. Additional labels are available

from Domino Printing Sciences plc as part of the Guarding Labels Kit, Part

Number L007628.

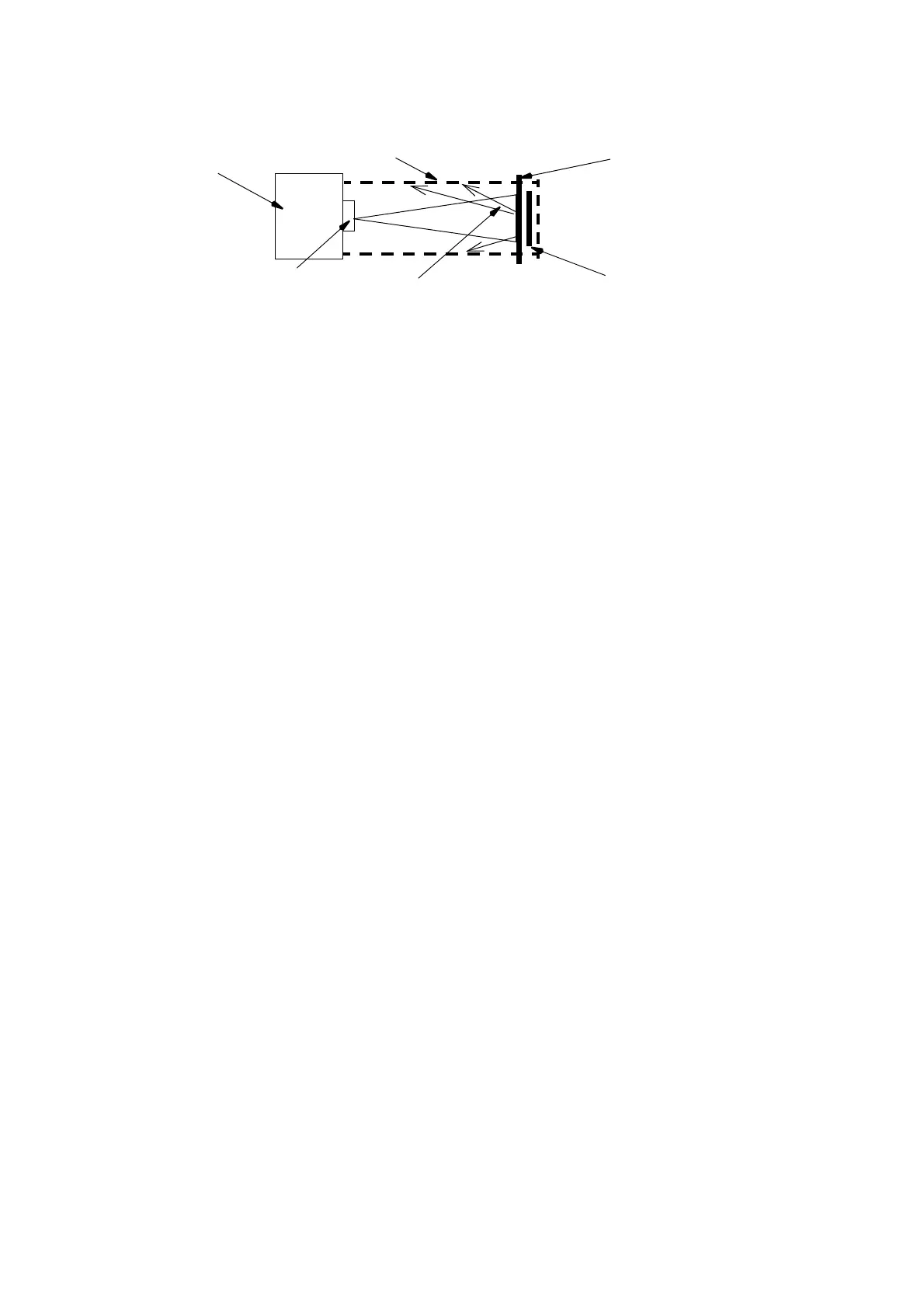

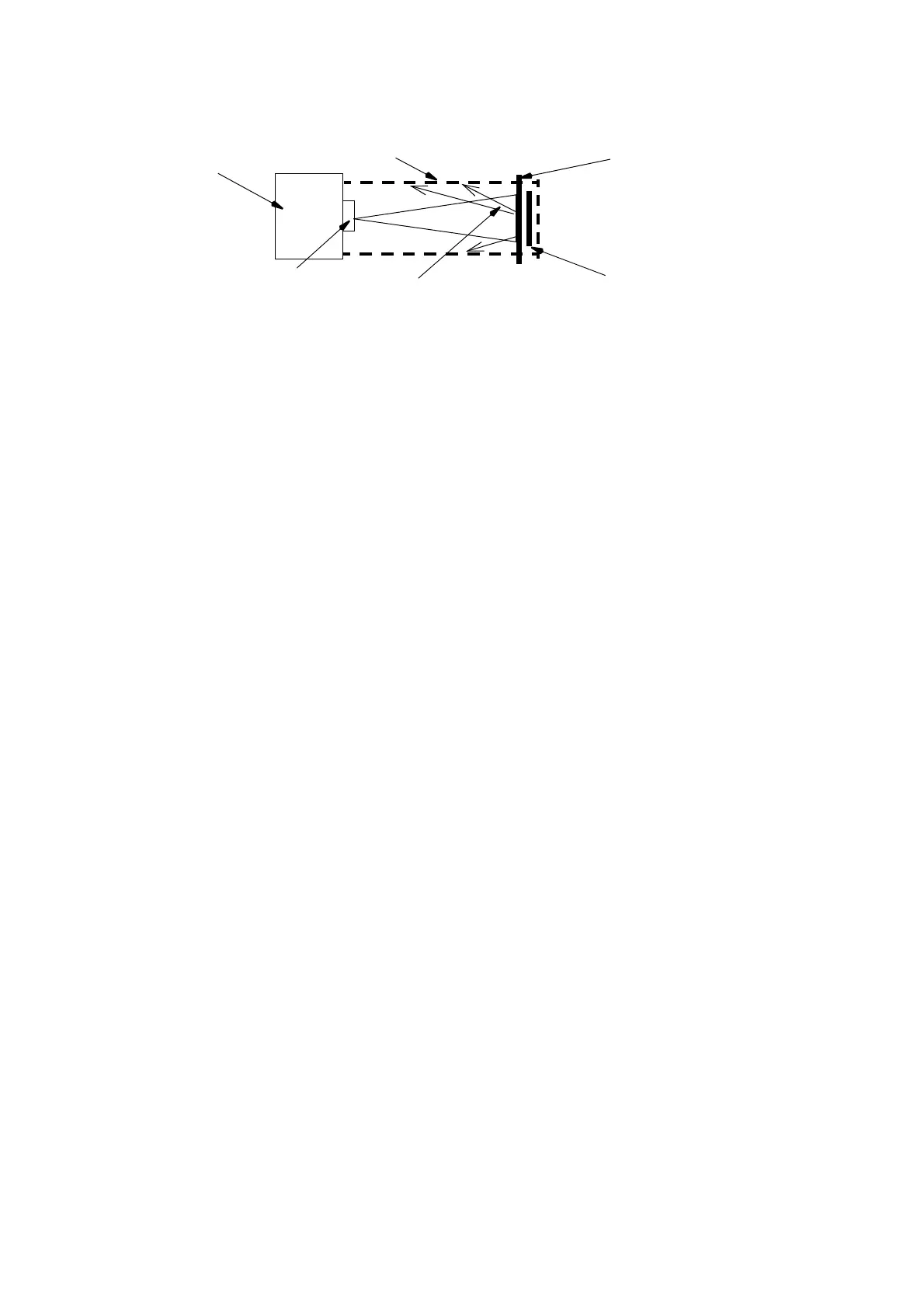

Substrate

Laser Beam Path

Access Guard

Laser Head

Lens

Beam Stop

Loading...

Loading...