INSTALLATION

L025317 Issue 1 March 2011 2-35

COMPRESSED AIR CONNECTION,

CHILLING

The Laser Head is equipped with a connection for compressed air with a

typical flow rate of 280 litres per minute (10 cubic feet per minute (cfm)) -

actual air flow is duty cycle and ambient dependent. This air cools the laser

and keeps the objective lens free from dust. It requires a 12mm diameter

hose. The lens requires a constant flow at 5psi (0.3 bar). The D120 IP and

D320 IP provide an outlet to supply the lens with air.

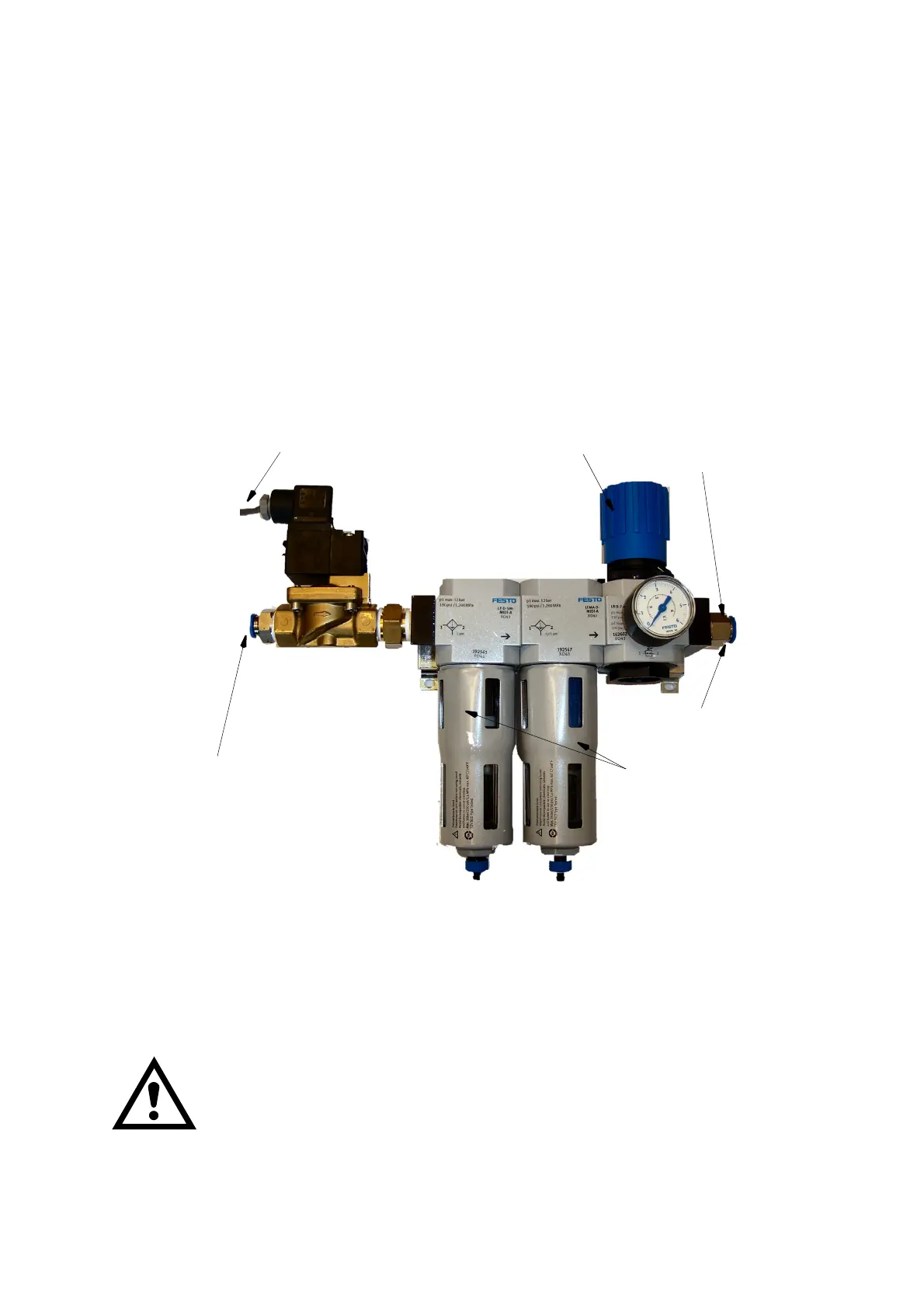

An optional air installation kit, for treating factory air that is to be supplied to

the laser head, is available. The air kit includes an air filter, regulator,

coalescing filter, a control solenoid and cable, fittings, and 12 meters of 12mm

tubing.

CAUTION: Only clean compressed air, free of oil, to Class 1.7.2 of

ISO8573 should be used to avoid damage to the lens and

laser tube.

Air Solenoid Cable

Connector to D-Series

10mm or 3/8"

OD Tubing

D-Series Air Kit

Pressure Regulator

In-Line Filters

Push-In

Connctor

12mm OD

Tubing to Laser

Push-In

Connctor

Notes: (1) Check that thread tape

is applied prior to assembly.

(2) Minimum 4 bar / 58 psi factory air supply needed to operate the air

kit

Loading...

Loading...