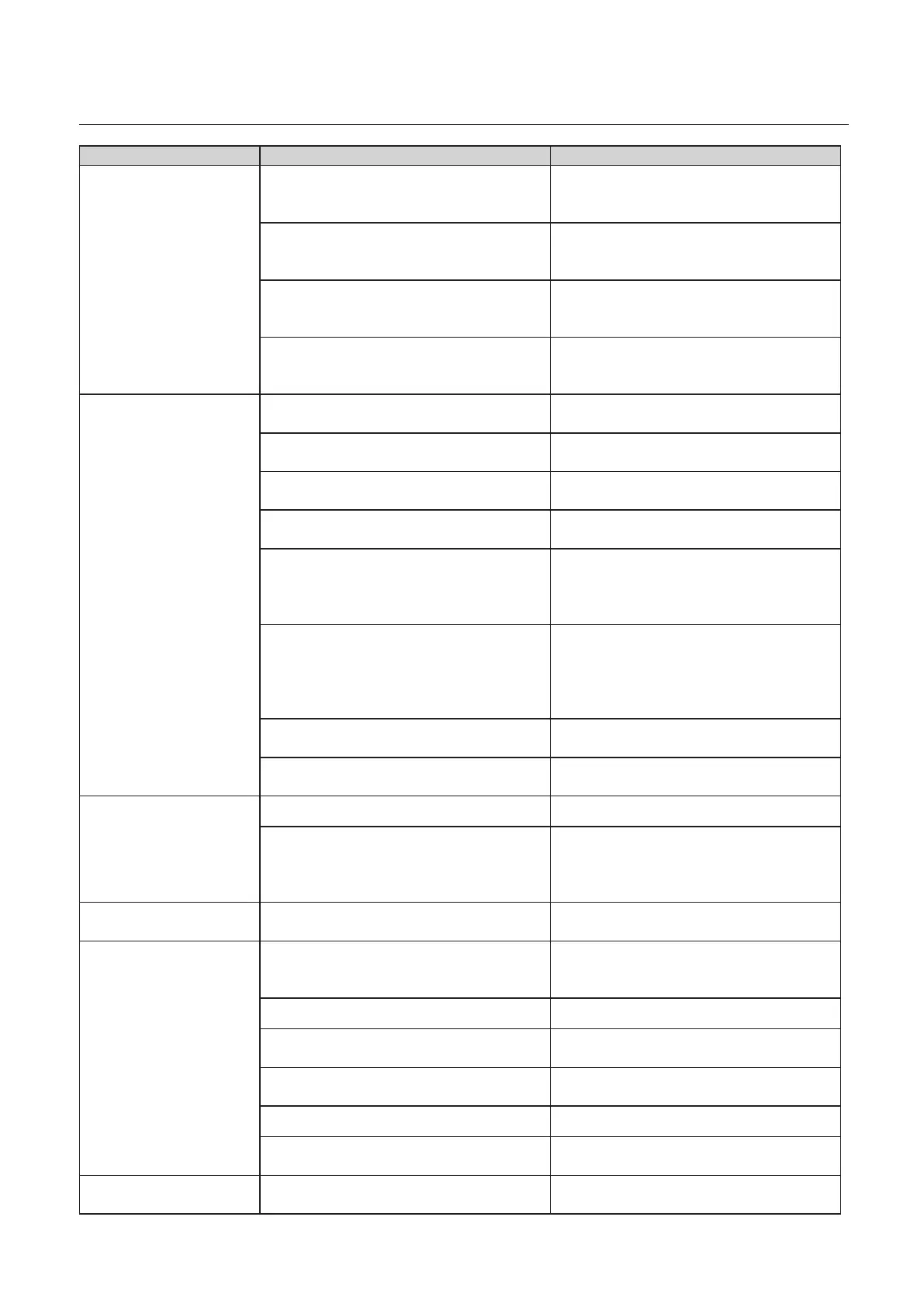

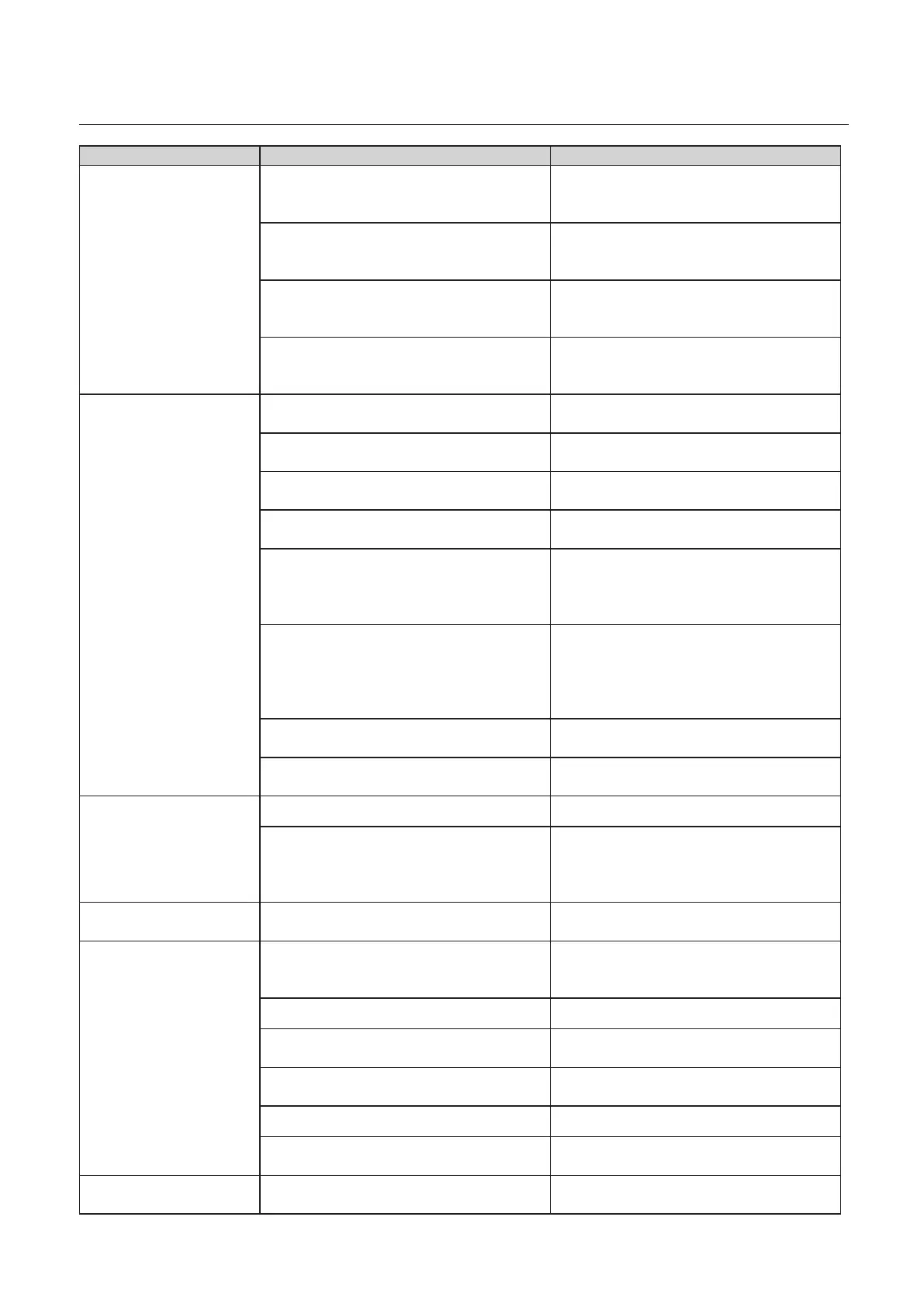

5-11

Chapter 5 Trouble Guide

Symptom Cause Solution

Paper jams in the

stitching section.

When delivering paper sheet by sheet, the

trailing edge of the paper oats and the

next paper strikes against it.

Lower the bracket of the infeed paper

holder.

(p.2-37)

When delivering paper sheet by sheet, the

air of the DBM-600 AIR KIT (option) is not

properly adjusted.

Adjust the air volume.

(p.3-2)

The gap between the stitching paper

holder and the conveyance guide is too

narrow for the paper thickness.

Widen the gap.

(p.2-37)

When delivering paper sheet by sheet and

saddle stitching it, the paper guide for side

stitching is used.

Use the paper guide for saddle stitching.

(p.2-16)

Paper alignment is poor. The stitching side guides are too distant

from each other.

Set the stitching side guides closer to each

other.

(p.2-21)

The space between the stitching back

guide and paper is too wide.

Narrow the space.

(p.2-21)

Because the number of jogs are small,

paper do not align.

Increase the number of jogs.

(p.2-27)

The paper guide for side stitching is not

used for side stitching.

Use the paper guide for side stitching.

(p.2-16)

Because the gap between the stitching

paper holder and the conveyance guide

is too wide for the paper thickness, paper

overrides the saddle-stitching stopper.

Narrow the gap.

(p.2-37)

Because the gap between the stitching

paper holder and the conveyance guide

is too wide for the paper thickness, paper

bend when it reaches the saddle-stitching

stopper.

Narrow the gap.

(p.2-37)

The stitching side guides are not parallel to

paper.

Adjust the angle of the stitching side

guides.

(p.2-32)

The saddle-stitching stopper is not parallel

to paper.

Adjust the angle of the saddle-stitching

stopper.

(p.2-32)

The stitching position is

not stable.

Paper alignment is poor. Refer to “Paper alignment is poor.”

Because the gap between the stitching

paper holder and the conveyance guide

is too wide for the paper thickness, paper

overrides the saddle-stitching stopper.

Narrow the gap.

(p.2-37)

The stitch is not at right

angles to paper.

The angle of the saddle-stitching stopper

is not appropriately adjusted.

Adjust the angle of the saddle-stitching

stopper.

(p.2-32)

Paper is not stitched. The pressure of the leaf spring attached to

the wire reel is so strong that the wire reel

cannot turn.

Decrease the pressure of the leaf spring.

(p.4-7)

There is no wire left. Install a new wire.

(p.4-7)

The wire jams inside the stitcher head. Remove the wire and adjust each section

of the stitcher head.

(p.4-4)

The triangular handle has been set to the

non-stitching position.

Set the triangular handle to the stitching

position.

(p.4-4)

The stitch release lever has not been set. Set the stitch release lever.

(p.3-2)

The stitcher head is not appropriately

adjusted.

Adjust each section of the stitcher head.

(p.4-4)

Stitches are deformed. The stitcher head is not appropriately

adjusted.

Adjust each section of the stitcher head.

(p.4-4)

Loading...

Loading...