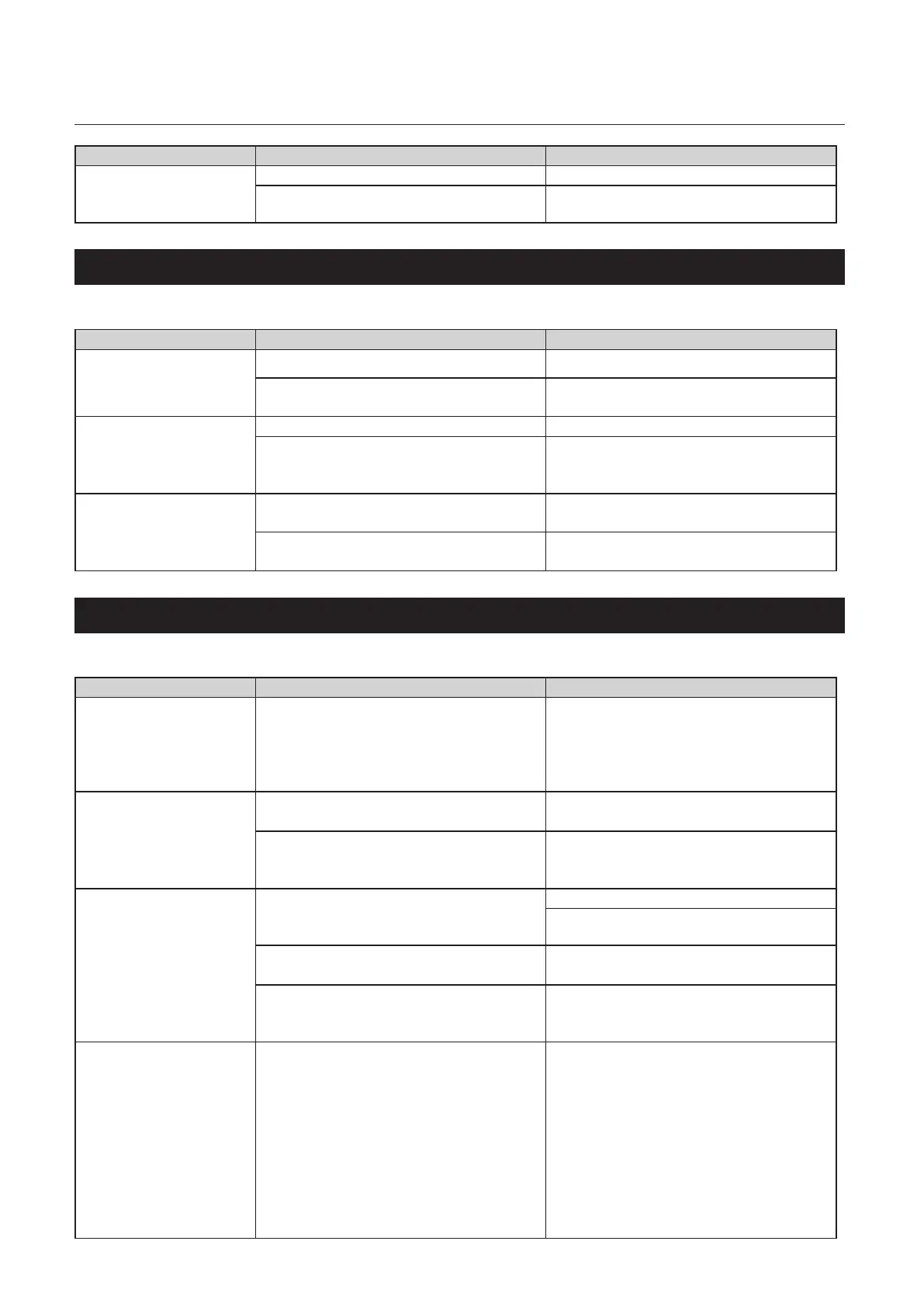

5-14

Chapter 5 Trouble Guide

Symptom Cause Solution

After a booklet is folded,

it is not smoothly ejected

from the paper exit.

The ejection pressure is too strong. Decrease the pressure.

(p.2-40)

The ejection pressure is too weak. Increase the pressure.

(p.2-40)

4-4. DBM-600 paper receiver and the stacker

Symptom Cause Solution

Paper does not align on

the paper receiver.

The paper receiving guides are not used. Use the paper receiving guides.

(p.2-41)

The paper receiver stopper is not adjusted. Adjust the position of the paper receiver

stopper according to the paper size.

(p.2-17)

Paper stands on the

paper receiver.

The paper guide bracket is not used. Use the paper guide bracket.

(p.2-41)

During corner stitching, the paper receiver

full loading sensor is set to the upper

position.

Lower the position using the paper receiver

full loading sensor height adjustment.

(p.2-42)

The booklet jams under

the paper guide roller

unit.

The position of the paper guide roller unit

is not appropriate.

Check the position of the paper guide

roller unit.

(p.2-46)

The conveyance start timing and the

stacker conveyance time is not appropriate.

Adjust them.

(p.2-47)

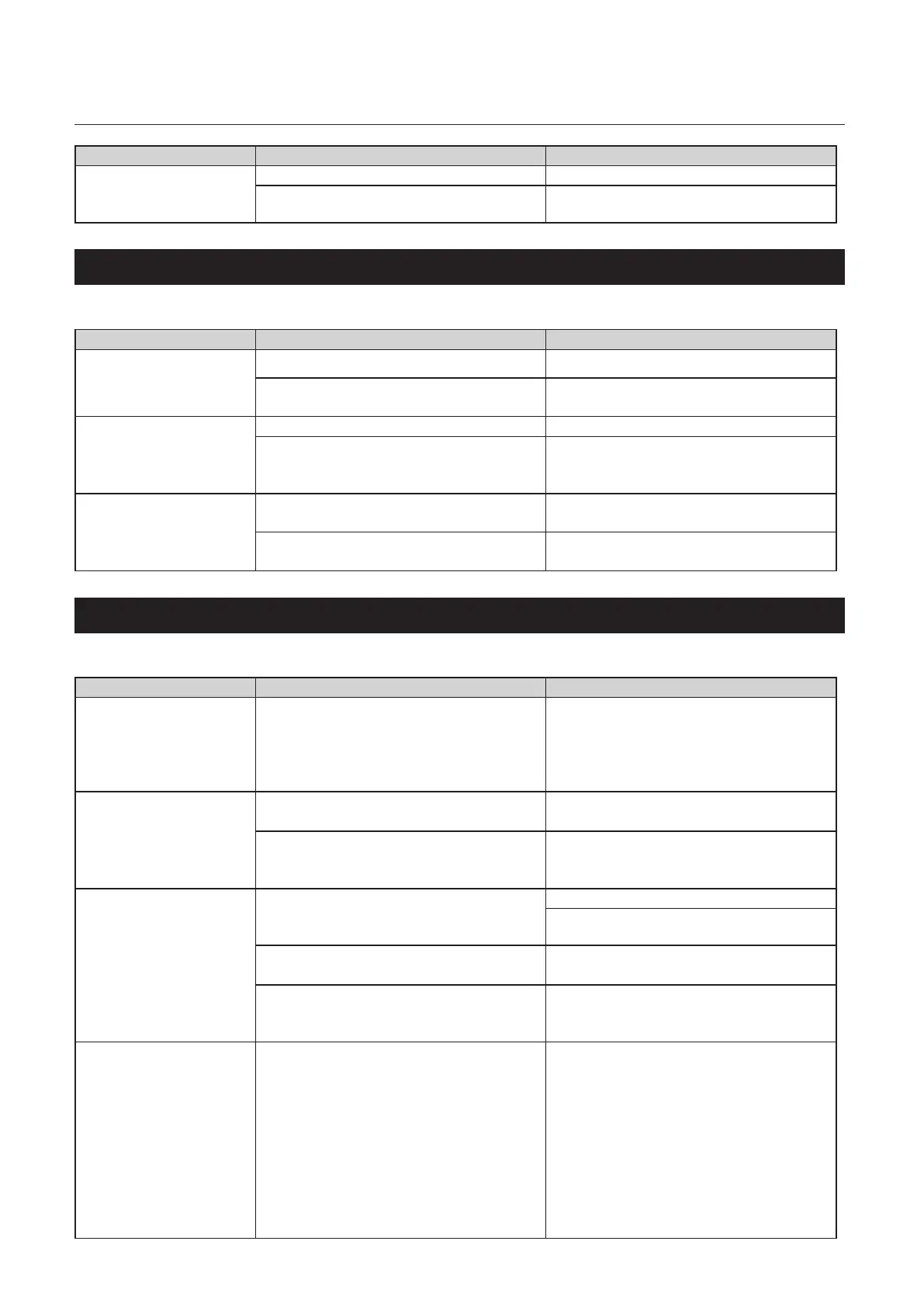

4-5. DBM-600T trimming section

Symptom Cause Solution

The booklet is not in

contact with the stopper

because it does not reach

the stopper or bounces

o the stopper.

The conveyance stop timing is not

appropriate.

Make the conveyance stop timing slower

on the control panel of the DBM-600 or the

PC CONTROLLER

(p.2-47)

. If the problem is not

solved yet, narrow the roller gap.

(p.2-19)

The booklet does not

enter the infeed roller.

The roller gap is too narrow. Widen the roller gap.

(p.2-19)

When the trimming width is 25 mm/0.98

inch or longer, the infeed roller unit is not

on the angle.

Place the infeed roller unit on the angle,

then widen the roller gap.

(p.2-19)

The cover sheet is wider

than the inner sheets

after trimmed.

The infeed rollers press the booklet too

tight.

Raise the infeed rollers.

(p.5-9)

Remove the spring of the infeed roller unit.

(p.5-9)

The roller gap is too narrow. Widen the roller gap.

(p.2-19)

The conveyance stop timing is not

appropriate.

Make the conveyance stop timing faster on

the control panel of the DBM-600 or the PC

CONTROLLER.

(p.2-47)

.

The booklet is trimmed

skewed.

Because the conveyance stop timing is not

appropriate, the booklet has not reached

the stopper. Or the stopper is skewed.

1) Make the conveyance stop timing slower

on the control panel of the DBM-600 or the

PC CONTROLLER

.(p.2-47)

.

2) If the problem is not solved after

completing step1) above, narrow the roller

gap.

(p.2-19)

3) If the problem is not solved after

completing step2) above, the stopper may

be skewed. Adjust the angle of the stopper.

(p.2-43)

Loading...

Loading...