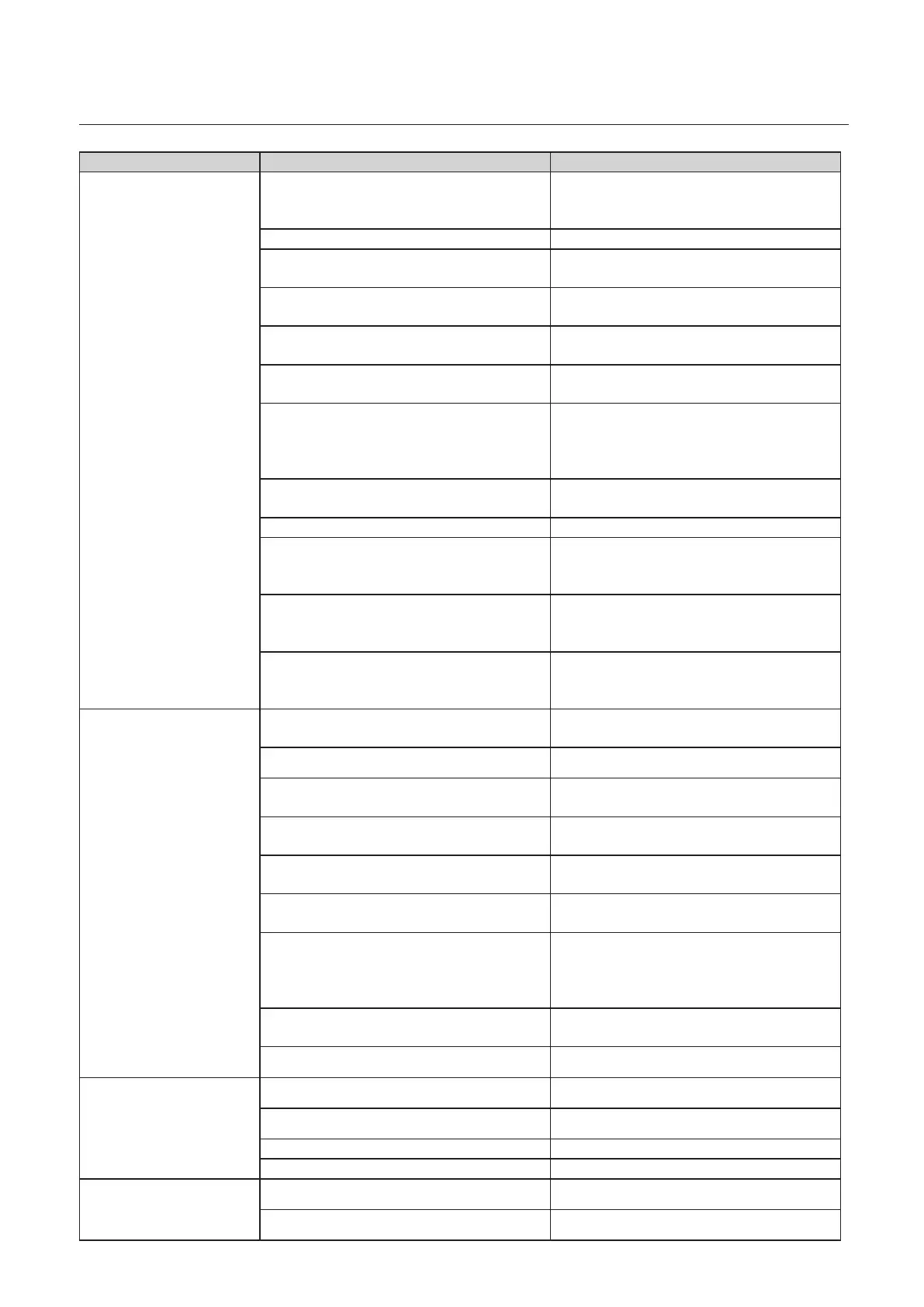

5-13

Chapter 5 Trouble Guide

Symptom Cause Solution

Paper is folded skewed. The angle of the folding side guides are

not adjusted using the fold misalignment

adjustment knob screw.

Adjust the angle.

(p.2-31)

Paper alignment is poor. Refer to “Paper alignment is poor.”

The folding side guides are too close to

each other.

Set the folding side guides distant from

each other.

(p.2-23)

The folding side guides are too distant

from each other.

Set the folding side guides closer to each

other.

(p.2-23)

The space between the folding back guide

and paper is too narrow.

Widen the space.

(p.2-23)

The space between the folding back guide

and paper is too wide.

Narrow the space.

(p.2-23)

Because the space under the fold paper

holder is too wide for the paper thickness,

paper bend when it reaches the folding

stopper.

Narrow the space.

(p.2-40)

The stitch is in the stitch prohibited area. Adjust the stitching width so that the stitch

is not in the stitch prohibited area.

(p.1-40)

The fold start timing is too early. Make the timing slower.

(p.2-39)

The position of the fold ejection roller gap

lever is dierent between the operator’s

side and the non-operator’s side.

Adjust the position so that it is the same on

the operator’s side and the non-operator’s

side.

(p.2-36)

The position of the press roller gap is

dierent between the operator’s side and

the non-operator’s side.

Adjust the position so that it is the same on

the operator’s side and the non-operator’s

side.

(p.2-36)

The position of the pressure adjustment

lever is dierent between the operator’s

side and the non-operator’s side.

Adjust the position so that it is the same on

the operator’s side and the non-operator’s

side.

(p.2-39)

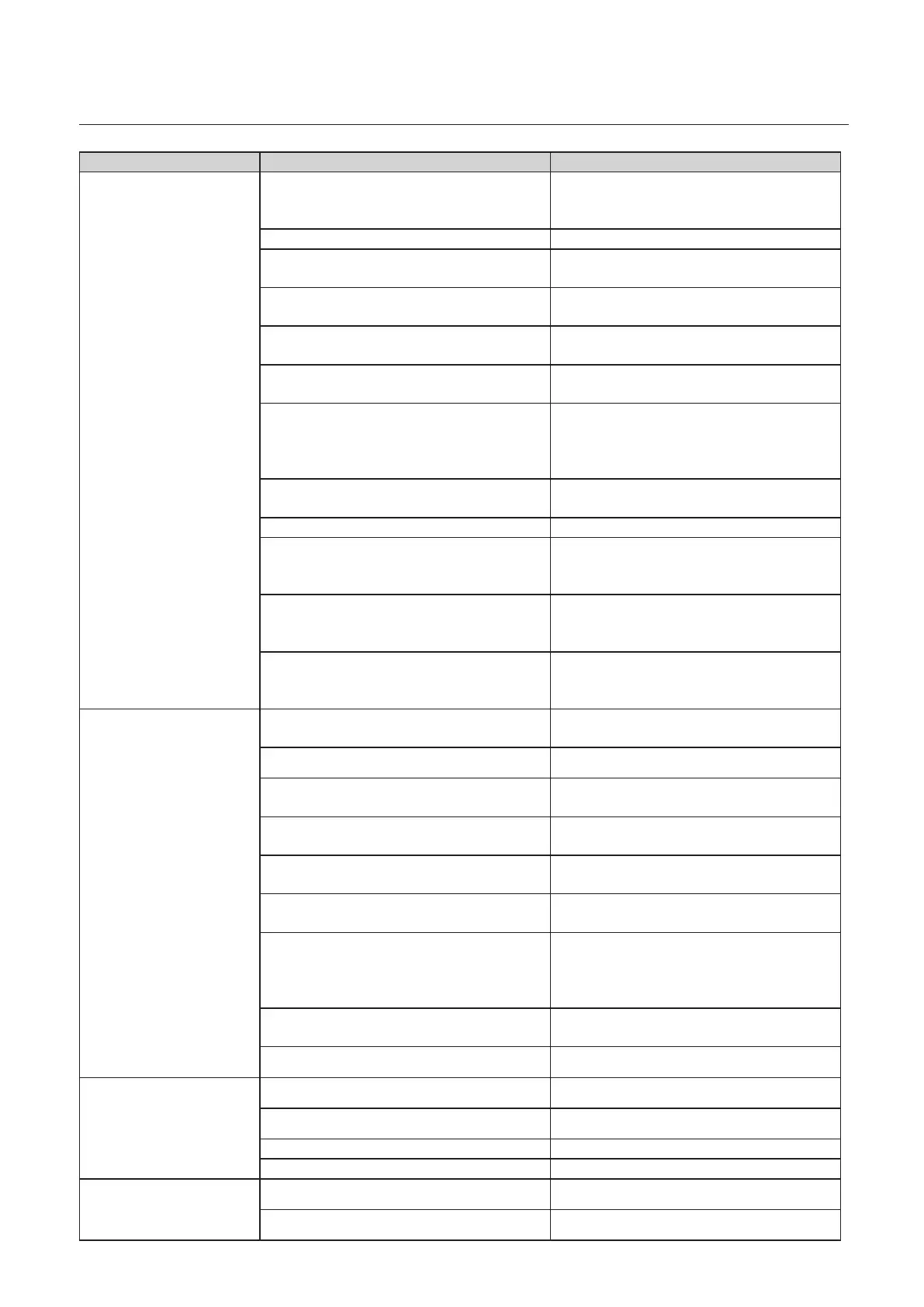

The folding position is

not stable.

The space under the fold paper holder is

too narrow for the paper thickness.

Widen the space.

(p.2-40)

Paper alignment is poor. Refer to “Paper alignment is poor.”

The folding side guides are too close to

each other.

Set the folding side guides distant from

each other.

(p.2-23)

The folding side guides are too distant

from each other.

Set the folding side guides closer to each

other.

(p.2-23)

The space between the folding back guide

and paper is too narrow.

Widen the space.

(p.2-23)

The space between the folding back guide

and paper is too wide.

Narrow the space.

(p.2-23)

Because the space under the fold paper

holder is too wide for the paper thickness,

paper bend when it reaches the folding

stopper.

Narrow the space.

(p.2-40)

The stitch is in the stitch prohibited area. Adjust the stitching width so that the stitch

is not in the stitch prohibited area .

(p.1-40)

The fold start timing is too early. Make the timing slower.

(p.2-39)

Paper stops at the folding

roller or the press roller.

The folding roller gap is too narrow. Widen the folding roller gap.

(p.2-38)

The folding roller gap is too wide. Narrow the folding roller gap.

(p.2-38)

The press roller pressure is too strong. Decrease the pressure.

(p.2-39)

The press roller pressure is too weak. Increase the pressure.

(p.2-39)

The surface of a booklet

is stripped at the press

roller.

The fold ejection roller gap is too narrow. Increase the gap.

(p.2-36)

The press roller gap is too narrow. Increase the gap.

(p.2-36)

Loading...

Loading...