GE H

EALTHCARE

D

IRECTION

GA091568, R

EVISION

5 VIVID E9 S

ERVICE

M

ANUAL

8 - 4 Section 8-2 - Warnings and important information

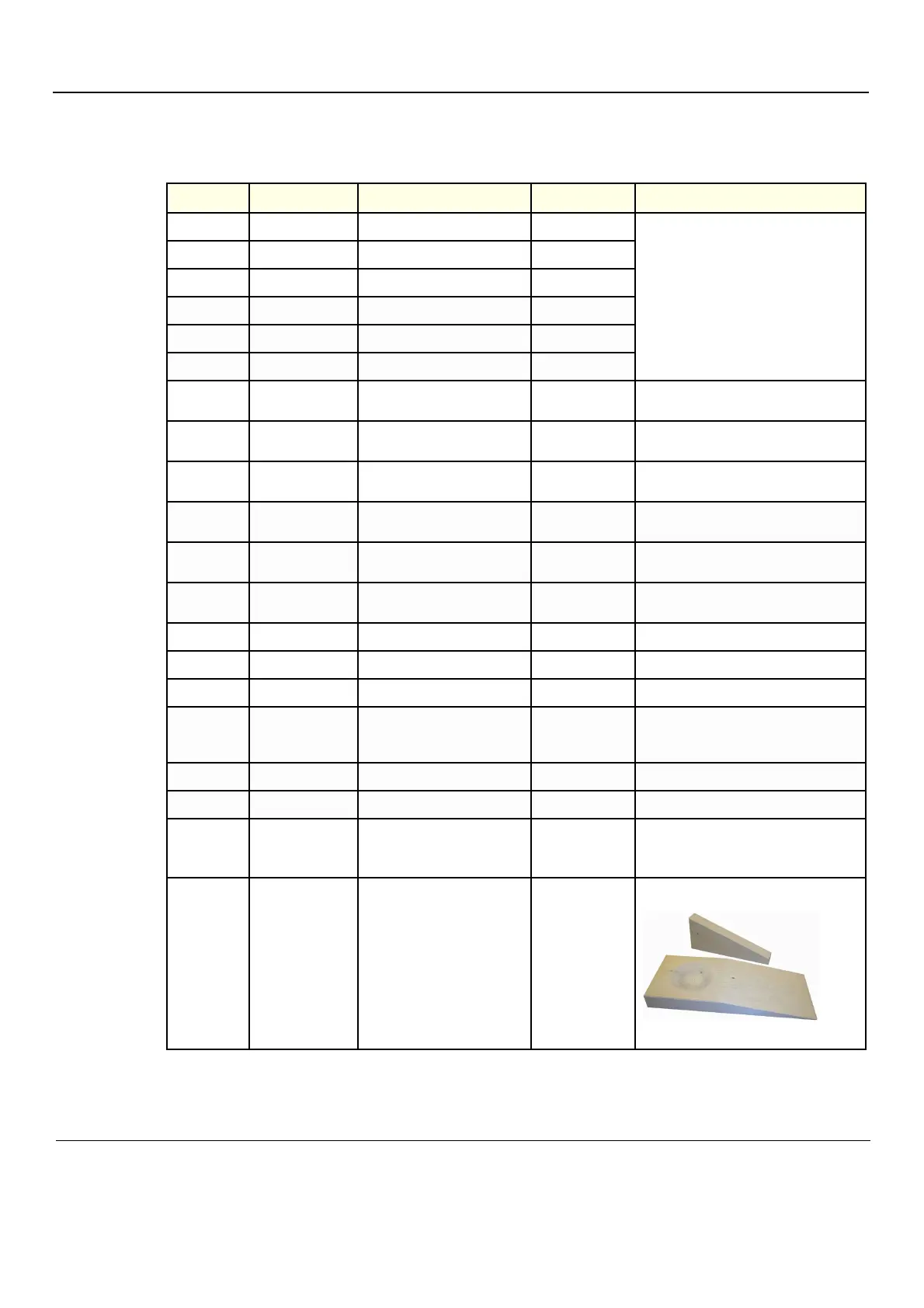

8-2-5 Tools needed for servicing VIVID E9

Table 8-1 Tools used for servicing VIVID E9

ITEM NO. TOOL SIZE TORQUE COMMENTS

1.

BIT # TX-10 M2.5

• Use Torque specified in procedure.

• If the torque is not indicated with the

procedure, hand tighten the screws/

nuts.

• 90 degree “L“ are suggested.

• A full set of 90 degree “L“ Torx

wrenches are recommended.

2.

BIT # TX-15 M3

3.

BIT # TX-20 M4

4.

BIT # TX-25 M5

5.

BIT # TX-30 M6

6.

BIT # TX-45 M10

7.

FLAT BLADE

SCREWDRIVER

3.2 mm

8.

FLAT BLADE

SCREWDRIVER

4 mm

9.

FLAT BLADE

SCREWDRIVER

6 mm

10.

PHILLIPS

SCREWDRIVER

PH1

11.

PHILLIPS

SCREWDRIVER

PH2

12.

PHILLIPS

SCREWDRIVER

PH3

13.

HEX KEY 5 mm (UNBRAKO KEY / ALLEN KEY)

14.

HEX KEY 8 mm (UNBRAKO KEY / ALLEN KEY)

15.

HEX KEY 10 mm (UNBRAKO KEY / ALLEN KEY)

16.

HEX KEY M12

REAR

CASTERS:

130 Nm

(UNBRAKO KEY / ALLEN KEY)

REAR CASTERS

17.

Nut Driver 5 mm

18.

Nut Driver 3/16 inch

19.

Torque Wrench,

Up to 81 Nm

Heavy mechanical parts may need a

specific torque. Each procedure will

indicate the torque needed.

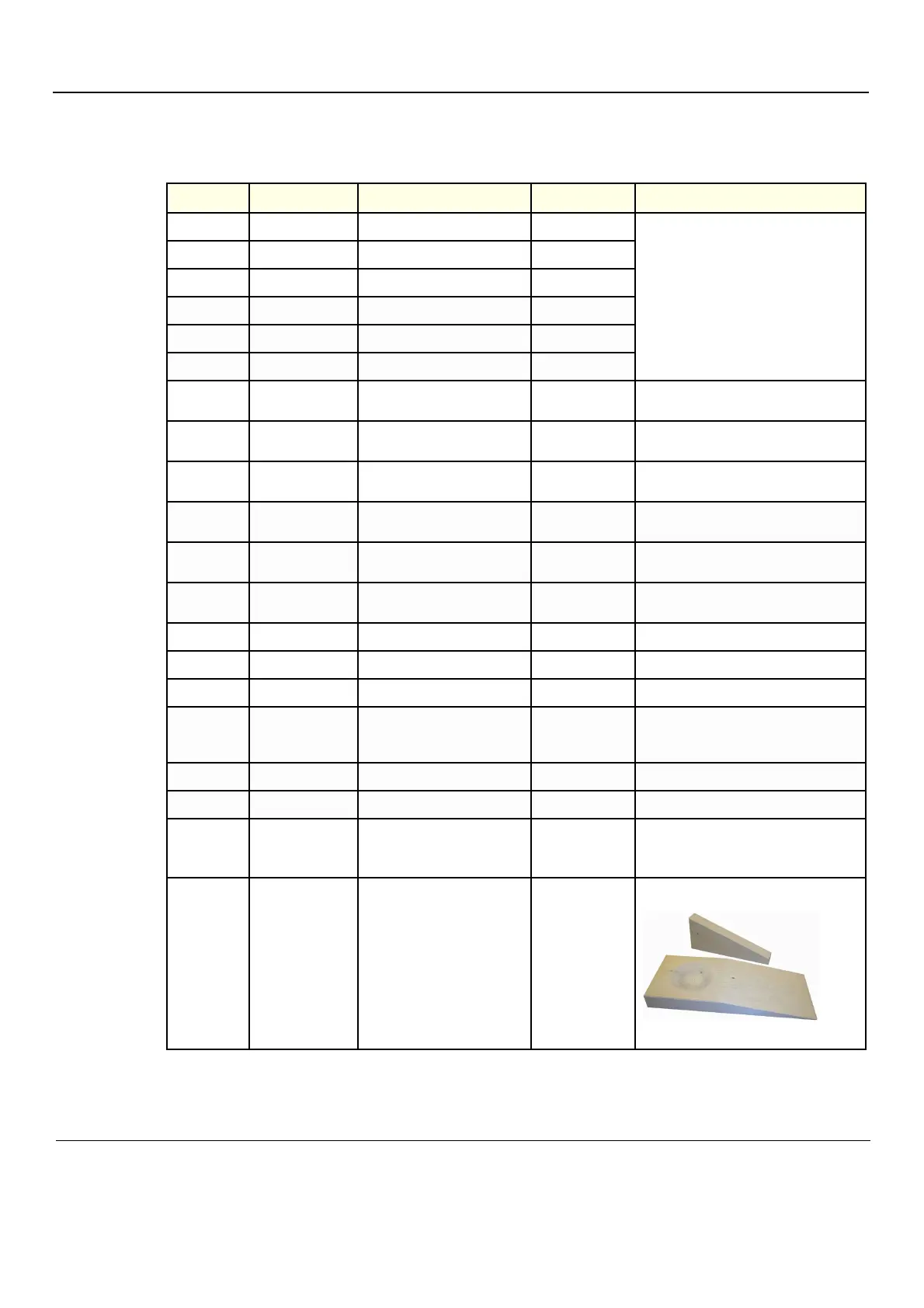

20.

WHEEL CHANGE

KIT

N/A N/A

FC200829

BEVEL EDGED BOARD

WOODEN WEDGE

Loading...

Loading...