Install and Set Up the Plasma Power Supply

60 810470 Operator Manual Powermax65/85/105 SYNC

Add additional gas filtration (if necessary)

It is extremely important to keep a clean, dry gas line to do the following:

Prevent oil, water, dirt, and other contaminants from causing damage to internal

components.

Get optimal cut quality and consumable life.

Dirty, oily air is the root cause of many common

problems that occur in Powermax systems, and in

some conditions it can void the warranty on the

plasma power supply and on the torch. Refer to

the gas quality recommendations in the ratings

tables that start on page 24.

The plasma power supply contains a built-in air

filter. Regularly do a check of the filter element

inside the air filter bowl and replace as necessary.

Refer to Examine the air filter bowl and filter

element on page 171.

The built-in air filter must not take the place of sufficient external filtration. If you work in an

environment that is extremely warm and humid, or if work site conditions introduce oil, vapors, or

other contaminants into the gas line, install an external filtration system that cleans the gas supply

before it gets into the plasma power supply.

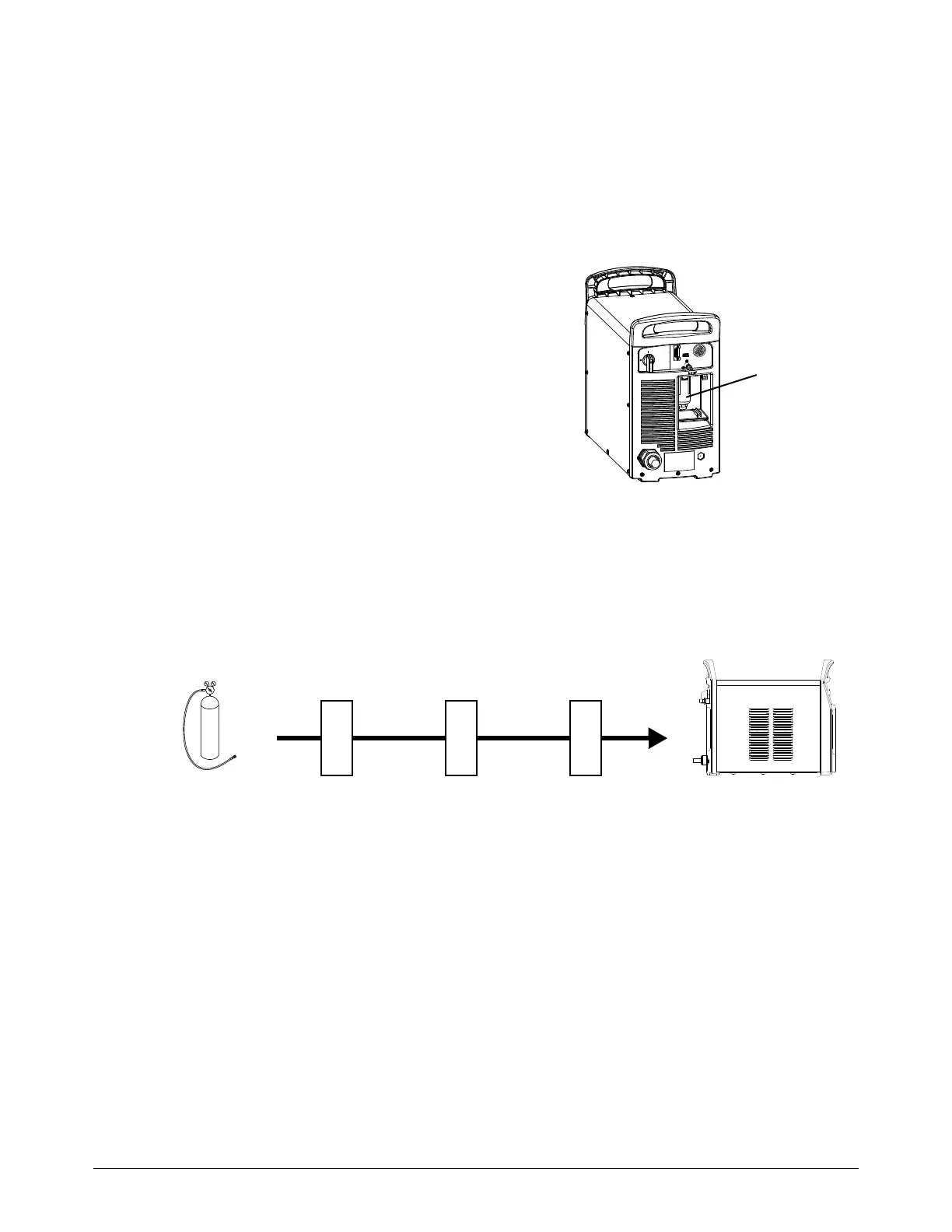

A 3-stage coalescing filtration system is recommended. A 3-stage filtering system works as follows

to clean contaminants from the gas supply.

The filtering system must be installed between the gas supply and the plasma power supply.

Additional gas filtration can make higher pressure from the gas supply

necessary. For the recommended gas inlet flow rate and pressure, refer to

Inlet gas pressure requirements (while gas is flowing) on page 58.

Gas supply Water and

particle filter

Oil filter Plasma power

supply

Oil vapor filter

Loading...

Loading...