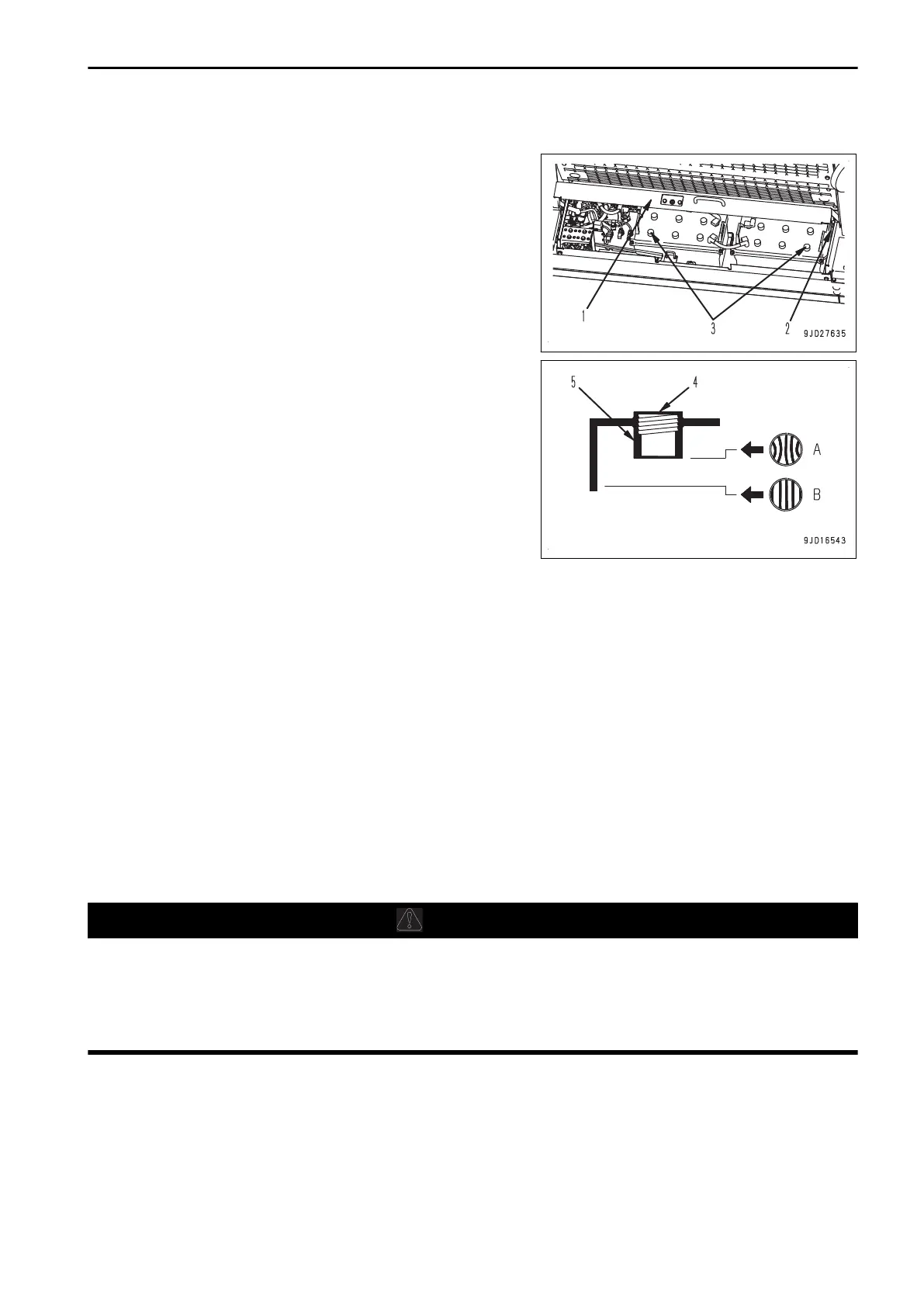

The battery box is on the front of the machine.

1.

Open the cover (1) of the battery box.

Open the cover (1) of the battery box fully, and it is se-

cured by rod (2).

2.

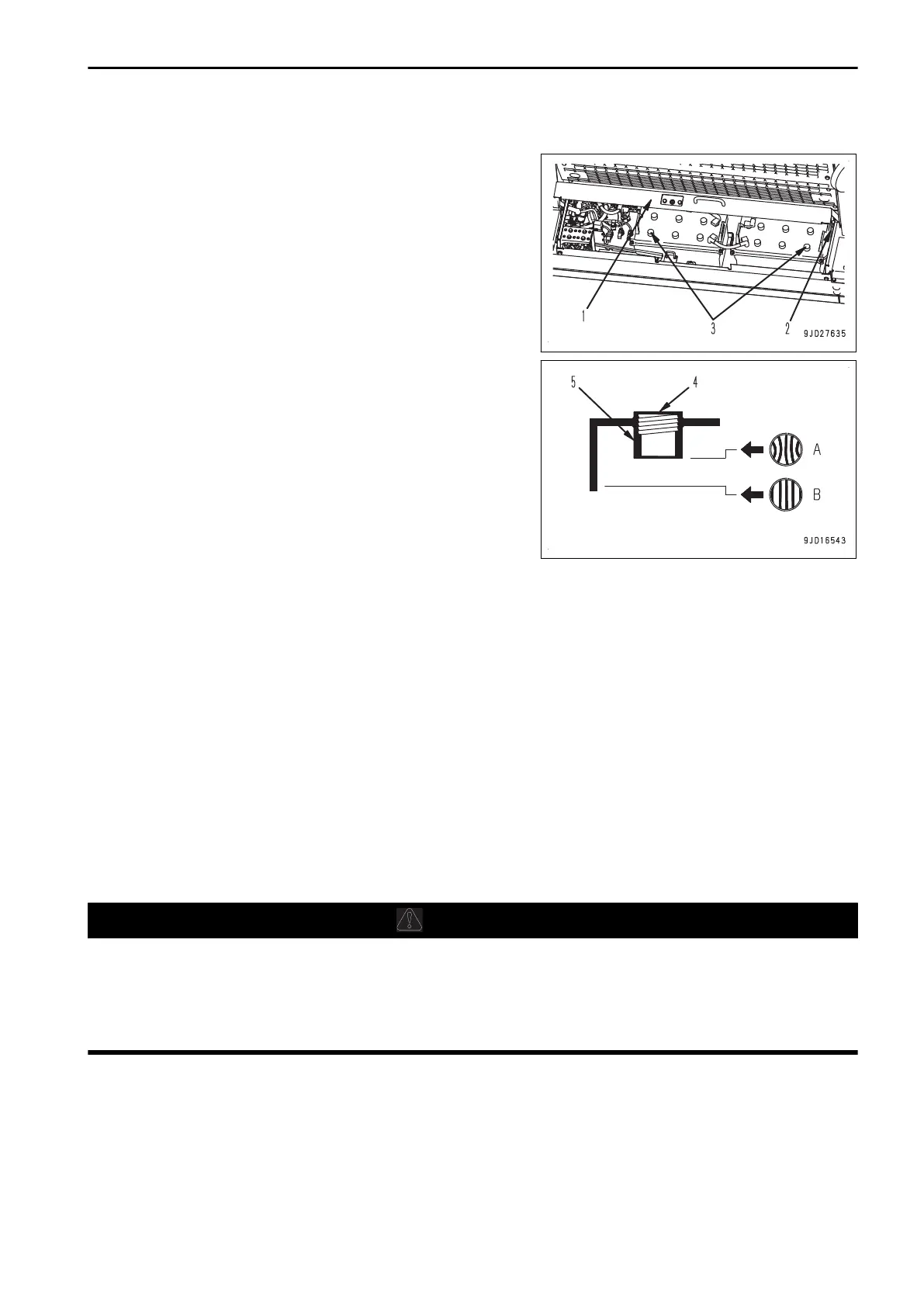

Remove the cap (3) at the top of the battery and check the

electrolyte level through electrolyte filler port (4).

3.

If the electrolyte does not reach the sleeve (5), always add

the purified water (such as a commercial battery fluid) so

that the level reaches the bottom of the sleeve (UPPER

LEVEL line).

• (A) Correct level: Electrolyte level is up to bottom of

sleeve, so surface tension causes electrolyte surface

to bulge and pole plate appears to be warped.

• (B) Low level: Electrolyte level does not reach the bot-

tom of sleeve, so pole plate appears straight and not

to be warped.

4.

When you add the battery fluid to the cell of cap (3), add it to other cells as well.

5.

After adding, tighten the cap (3) securely.

REMARK

If the battery fluid is added to the level above the bottom of the sleeve, use a syringe to remove it until the

level becomes under the bottom of the sleeve. Neutralize the removed fluid with baking soda (sodium bicar-

bonate), then flush it away with a large amount of water. If necessary, consult your Komatsu distributor or a

battery manufacturer.

6.

Release the lock of battery box cover (1), and close the cover.

METHOD FOR CHECKING ELECTROLYTE LEVEL ON INDICATOR ETC

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

METHOD FOR CLEANING TRANSMISSION CASE AND BRAKE SUB-TANK

BREATHER

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• When performing the check of the machine with the dump body raised, always set the dump lever to

“HOLD” position, lock it with the dump lever lock knob, then use the body pivot pin for further safe-

ty.

1.

Raise the dump body.

2.

Fix the dump body with the dump body pivot pin.

MAINTENANCE MAINTENANCE PROCEDURE

4-43

Loading...

Loading...