3.

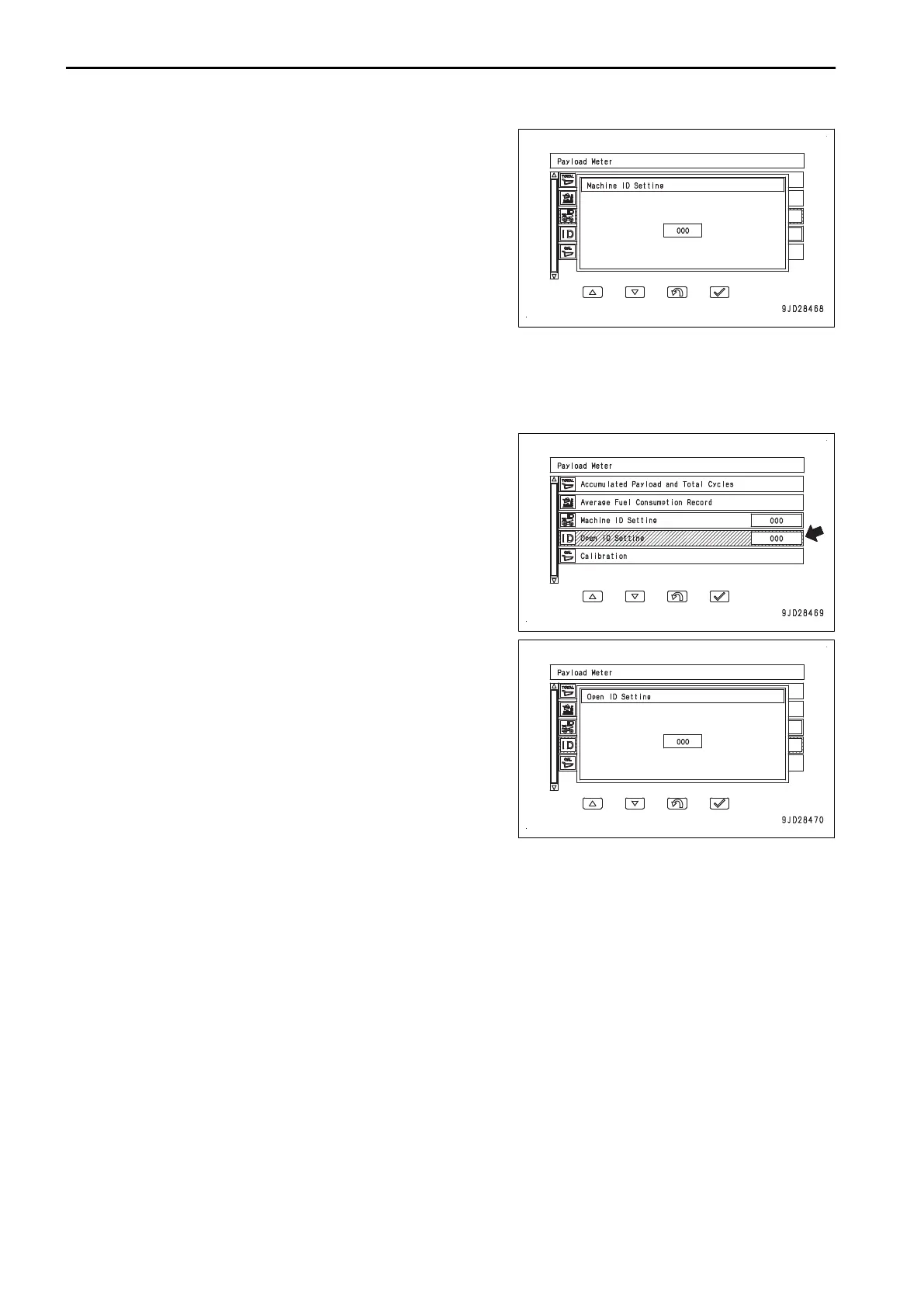

Press ENTER switch (2).

The pop-up window opens and displays the currently set

machine ID. Input the machine ID.

• The settable range is from 0 to 200.

• Each time UP switch (3) is pressed, ID increases by 1.

Each time DOWN switch (4) is pressed, ID decreases

by 1.

• If UP switch (3) is held down, ID increases rapidly. If

DOWN switch (4) is held down, ID decreases rapidly.

• If UP switch (3) is pressed when 200 is displayed as

ID, ID returns to 0. If DOWN switch (4) is pressed when 0 is displayed as ID, it becomes 200.

4.

After inputting the machine ID, press ENTER switch (2).

The value at this time is set as ID, and the windows closes.

If you press RETURN switch (5), the window closes without changing the value of ID.

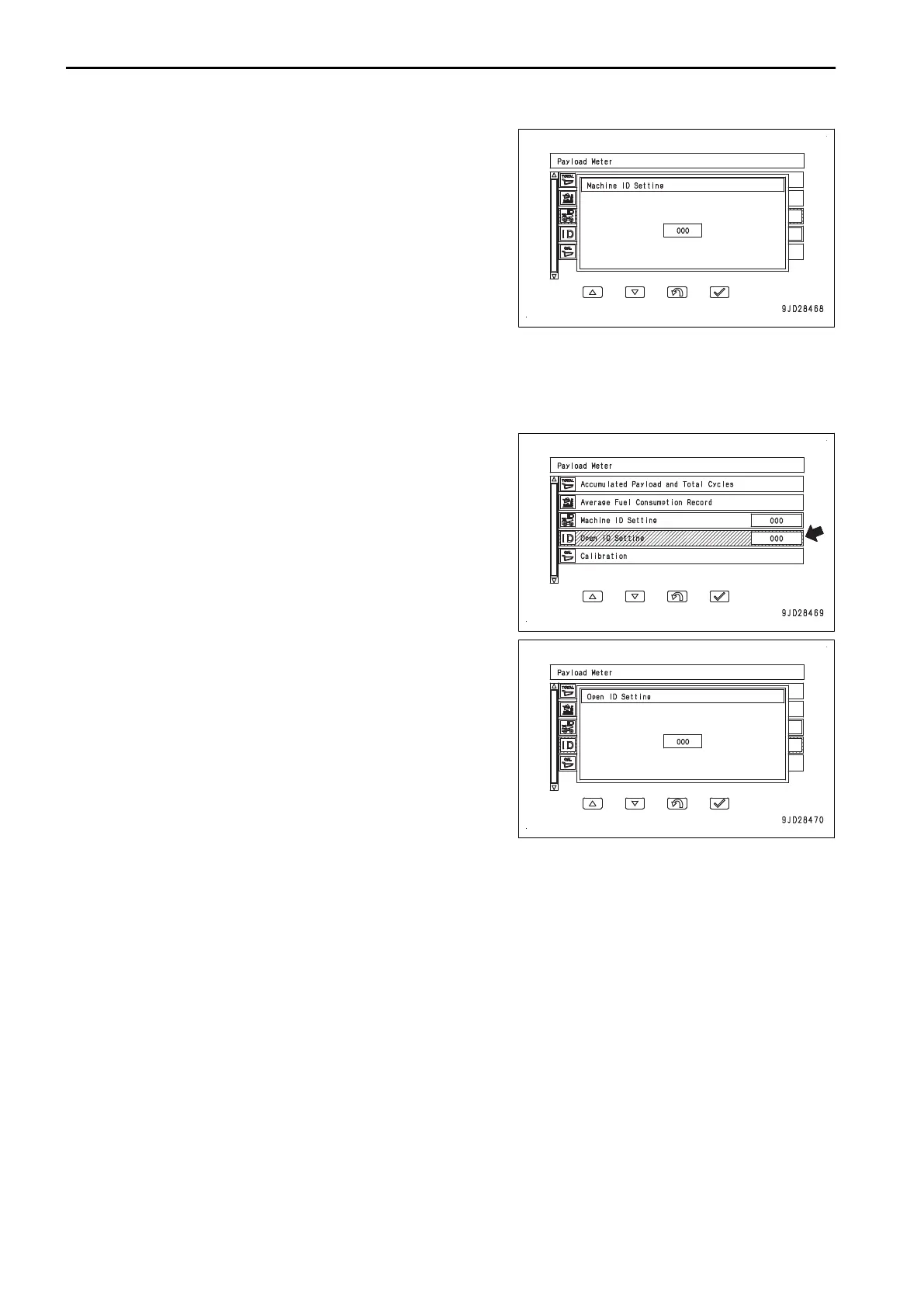

5.

Select “Open ID Setting” on the screen of step 2 for setting

the open ID.

The set open ID is displayed on the right side.

6.

The setting procedure for the open ID is the same with the

machine ID.

Set the open ID.

METHOD FOR PERFORMING CALIBRATION

Perform the calibration in the following cases.

• When the machine or payload meter is delivered

• Once a month

• When the suspension cylinder gas pressure and oil quantity are adjusted (When the suspension is adjus-

ted)

• When the suspension pressure sensor is replaced

• When the machine is modified and the empty weight of the machine changes by 100 kg or more.

HANDLING PAYLOAD METER ATTACHMENTS AND OPTIONS

6-12

Loading...

Loading...