Safety instructions

Thermal motor monitoring

Self−ventilated motors

2

24

EDBCSXM064 EN 11.0

2.2.2 Self−ventilated motors

Due to the construction, self−ventilated standard motors are exposed to an increased heat

generation in the lower speed range compared to forced ventilated motors.

Warnings!

For complying with the UL 508C standard, you have to set the

speed−dependent evaluation of the permissible torque via code C0129/x.

Parameter setting

The following codes can be set for I

2

x t monitoring:

Code Meaning Value range Lenze setting

C0066 Display of the I

2

x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

C0129/1 S1 torque characteristic I

1

/I

rated

10 ... 200 % 100 %

C0129/2 S1 torque characteristics n

2

/n

rated

10 ... 200 % 40 %

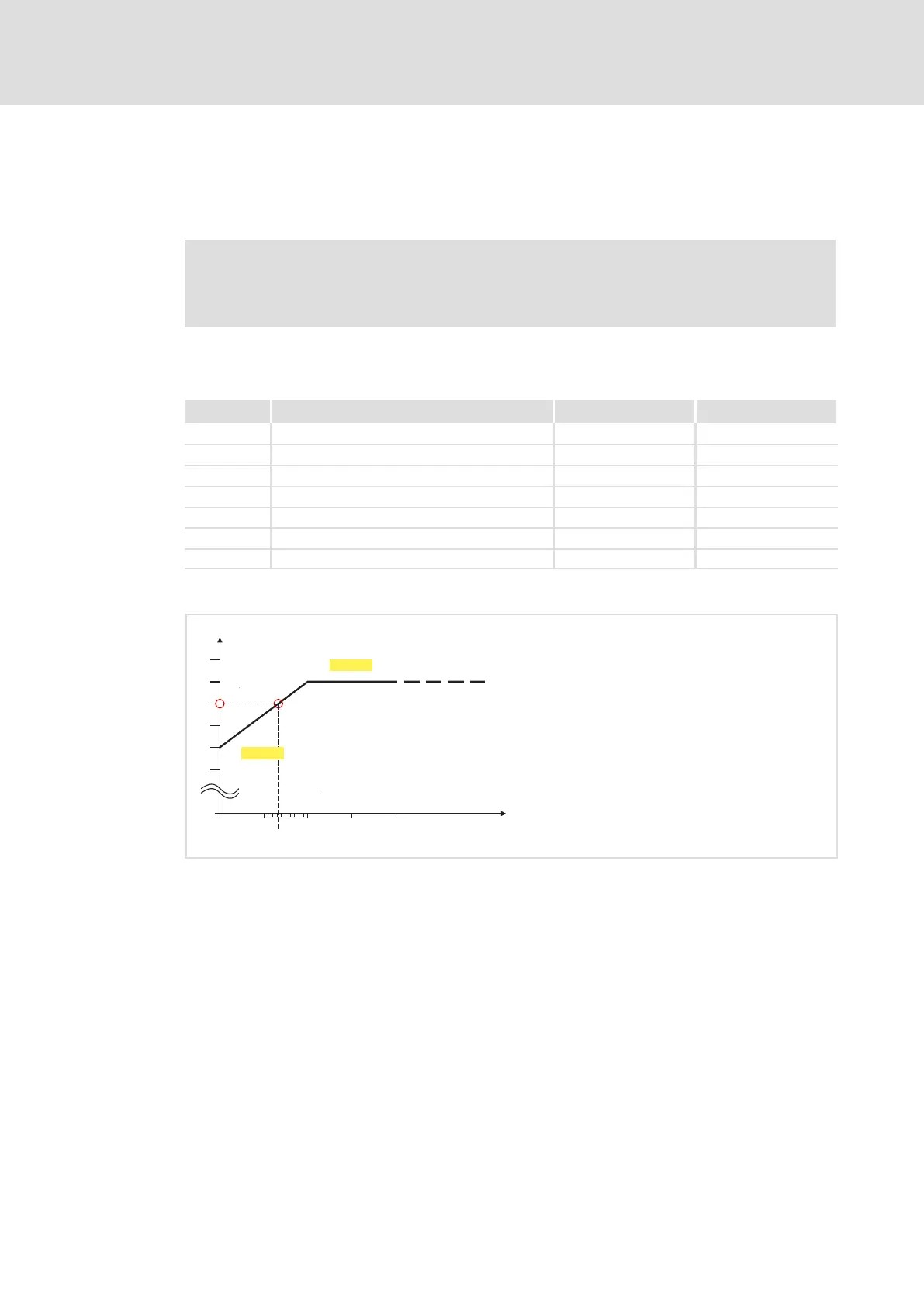

Effect of code C0129/x

0

0.9

0 0.1

C0129/2

0.2 0.3 0.4

0.6

0.7

0.8

1.0

1.1

1

0

0.132

2

I / I

N

n / n

N

C0129/1

3

9300STD350

Fig. 2−2 Working point in the range of characteristic lowering

The lowered speed / torque characteristic (Fig. 2−2) reduces the permissible thermal load

of self−ventilated standard motors. The characteristic is a line the definition of which

requires two points:

ƒ Point : Definition with C0129/1

This value also enables an increase of the maximally permissible load.

ƒ Point : Definition with C0129/2

With increasing speeds, the maximally permissible load remains unchanged

(I

Mot

= I

rated

).

In Fig. 2−2, the motor speed and the corresponding permissible motor torque () can be

read for each working point (on the characteristic () ... ). can also be calculated

using the values in C0129/1and C0129/2 (evaluation coefficient "y", 25)

Loading...

Loading...