Manitowoc Published 09-10-14, Control # 065-24 2-27

14000 SERVICE MANUAL HYDRAULIC SYSTEM

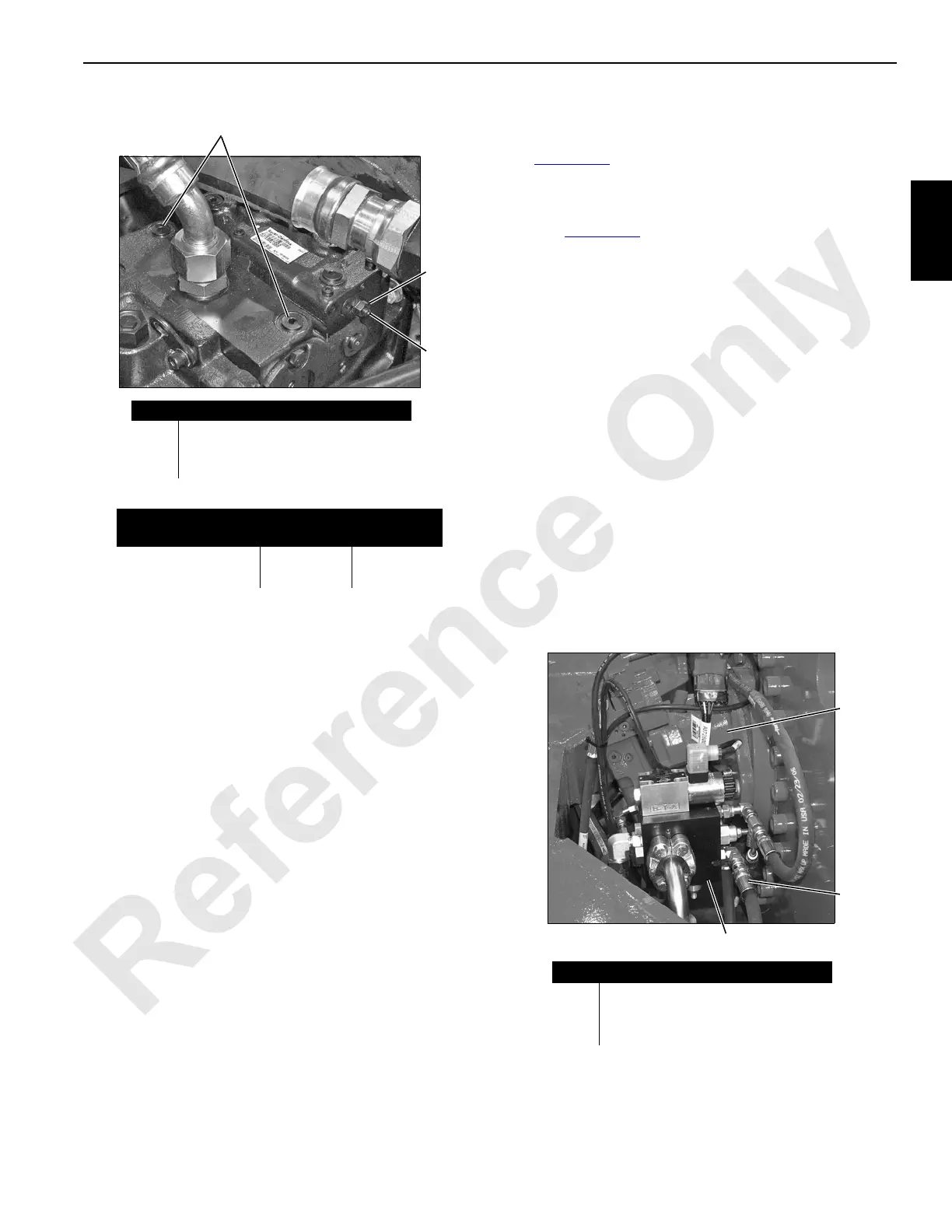

5. Loosen lock nut (2).

6. Using an internal hex wrench, turn adjusting screw (3) in

until pressure increases in either gauge.

7. Note angular position of internal hex wrench.

8. Then, turn adjusting screw out until pressure increases

an equal amount in other gauge.

9. Again, note angular position of internal hex wrench.

10. Turn adjusting screw in half the distance between

positions noted above.

11. Pump control should now be in neutral with both gauges

reading same pressure.

12. Hold adjusting screw (3) in position and securely tighten

lock nut (2).

13. Stop the engine, remove gauges, and securely install

servo gauge port plugs (1).

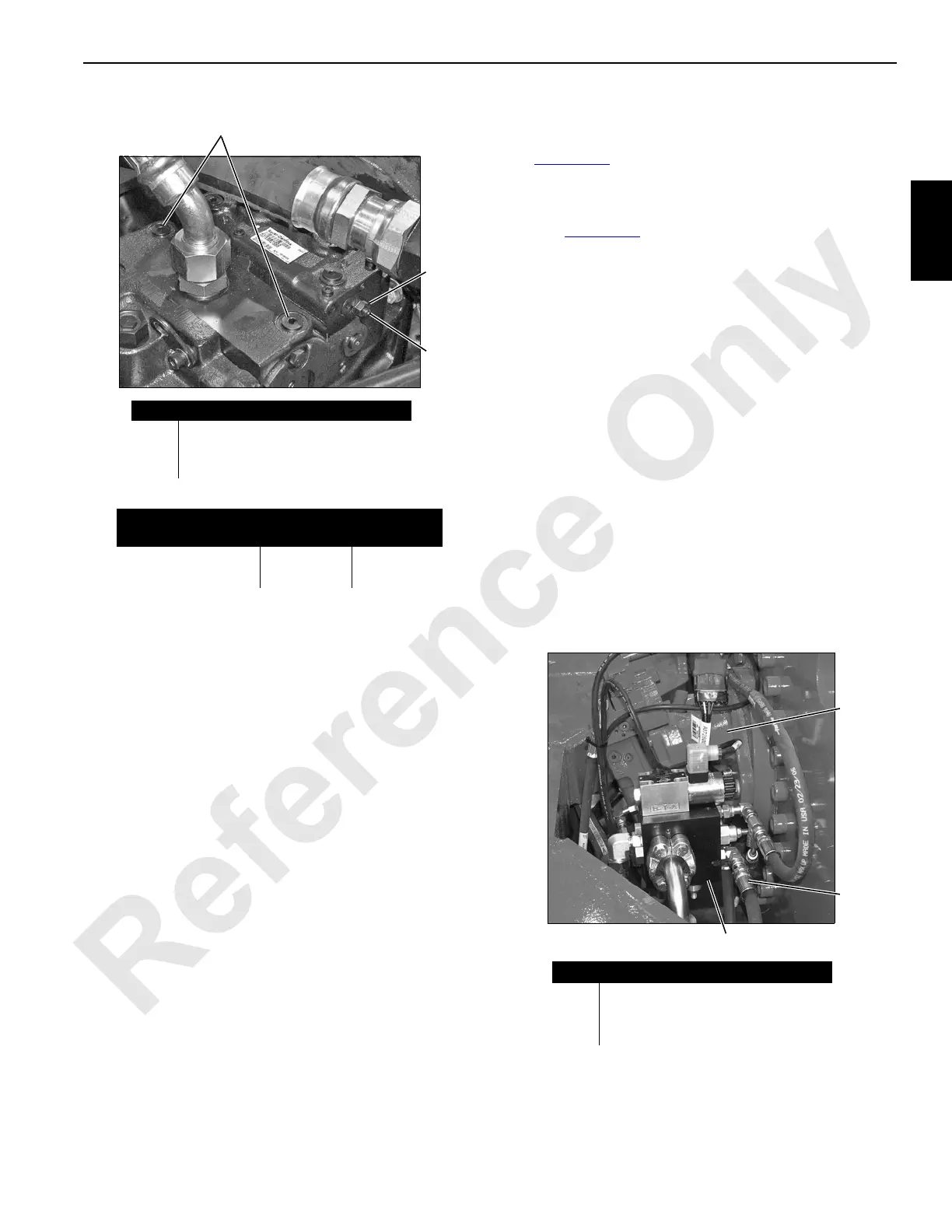

Motor Leakage Test

Perform the following test if troubleshooting indicates the

need:

• Low Charge Pressure

• Sluggish Operation

• Excessive Heat

See Figure 2-28

for the following procedure.

1. Stop the engine.

2. Install an accurate flow meter in highest case drain port

(see Figure 2-13

) at desired motor.

• A 3,000 psi (207 bar) in-line meter with a flow rate of

30 gpm (114 L/m) is required.

• All motors except swing require 16 ORS fittings.

Swing requires 12 ORS fittings.

3. For hoist motors only, disable loop flushing as follows:

a. Disconnect loop flushing hose (2) from elbow in loop

flushing valve (1).

b. Install an 08 ORS cap on end of elbow and an 08

ORS plug in end of hose.

4. Start and run the engine at high idle.

5. Monitor flow meter. Under all operating conditions,

leakage should not be more than 1-1/2 to 2-1/2 gpm (5.7

to 9,5 L/m.

6. Stop the engine and enable loop flushing by

reconnecting hose to elbow in loop flushing valve.

7. Start and run the engine at high idle.

1

2

Item Description

1 Servo Gauge Ports (SAE 06)

2 Lock Nut

3 Adjusting Screw

Wrench Size

Pump Series

Lock Nut

Hex Size

Internal

Hex Size

Early Series Units 17 mm 5 mm

Current Series Units 10 mm 3 mm

FIGURE 2-27

P1535a

Typical Pump Installation

3

FIGURE 2-28

Typical Motor Installation

Item Description

1 Loop Flushing Valve

2 Loop Flushing Hose

3 Motor

1

2

3

P2297b

Loading...

Loading...