POWER TRAIN 14000 SERVICE MANUAL

7-16

Published 09-10-14, Control # 065-24

ENGINE ENCLOSURE - CURRENT

PRODUCTION - TIER 3/4

The enclosure has panels that can be removed to allow

access for engine service.

Do not operate the crane without the enclosure in place and

all fasteners secure.

ENGINE BELT ROUTING

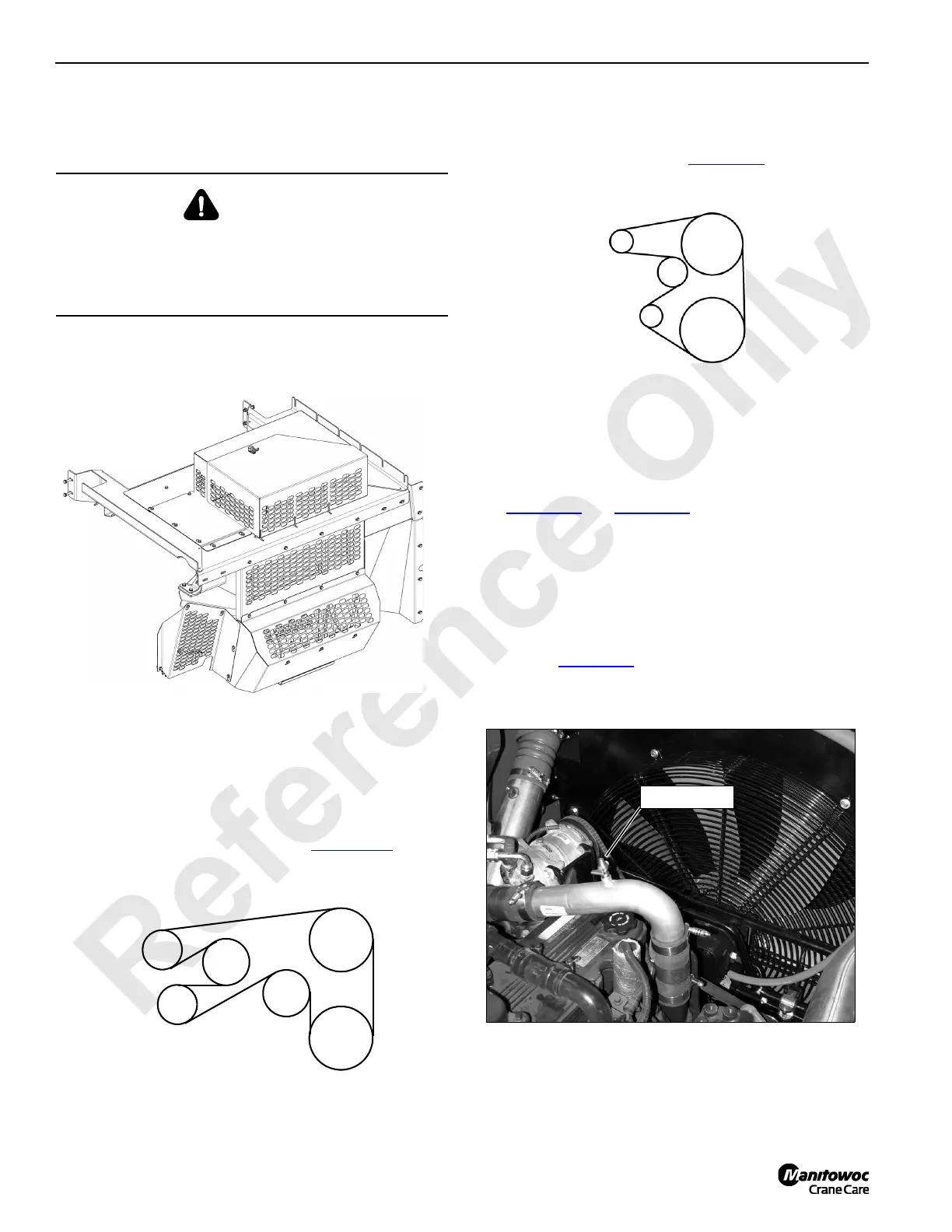

Engine Driven Fan - Past Production Tier 3

Engine fan belt routing is shown in Figure 7-10 to help

service personnel when installing a new fan belt on engine.

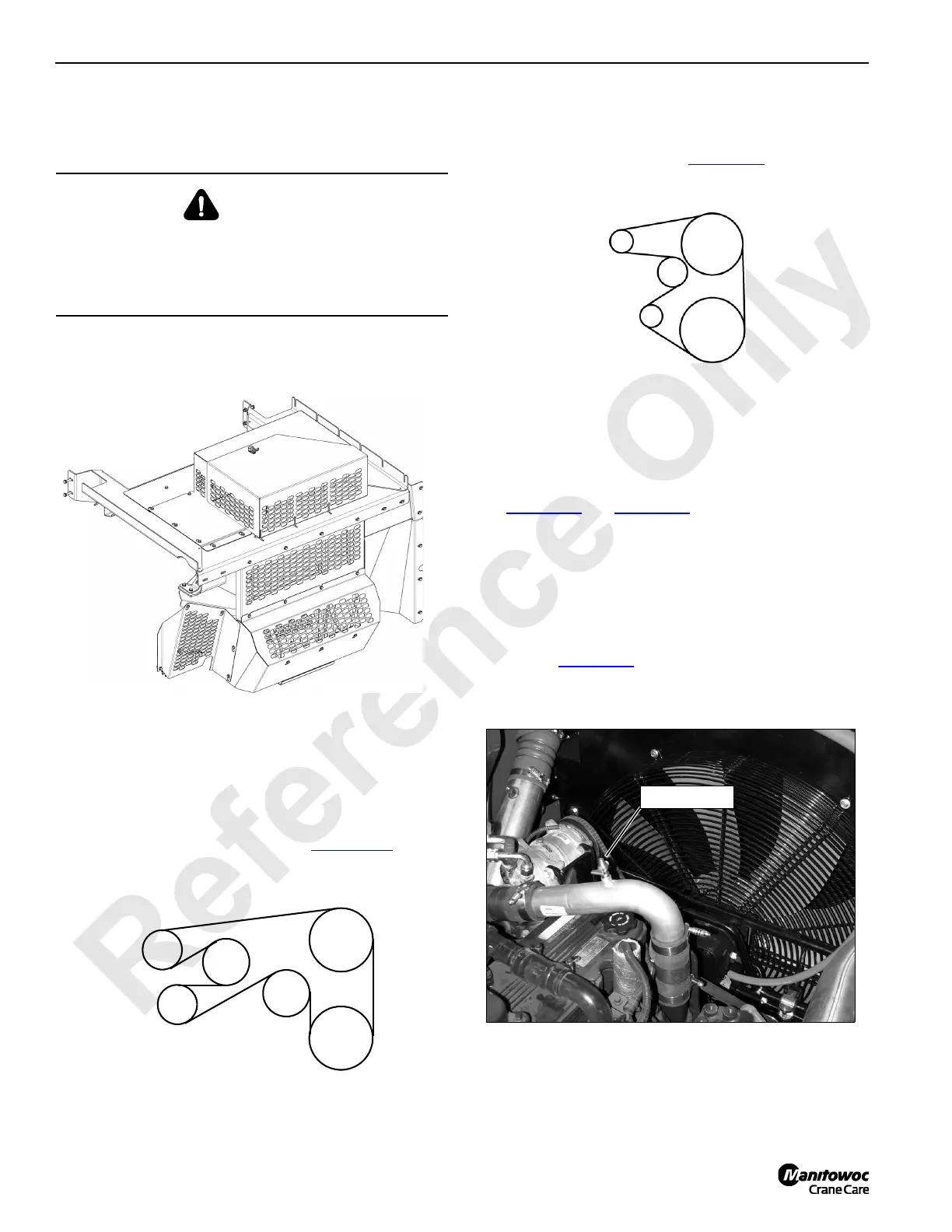

Hydraulic Driven Fan - Current Production

Tier 3/4

Engine belt routing is shown in Figure 7-11 to help service

personnel when installing a new fan belt on the engine.

ENGINE COOLING SYSTEM FILL -

CURRENT PRODUCTION - TIER 3/4

Add coolant to FULL (COLD) LEVEL as determined on

checks per the schedule in the engine owner’s manual.

See Figure 7-12

and Figure 7-13 for the following procedure

to replace coolant in a drained system:

1. Open the air bleed valve on the upper radiator tube. This

valve must be open during a radiator fill.

2. Add coolant to the radiator. Observe and close the

petcock when clear coolant appears at bleed valve.

3. Continue adding coolant until the level is at FULL

(COLD) Figure 7-13

.

NOTE: Maximum fill rate is 3 GPM (11.4 liters/min).

4. Run the engine until normal operating temperature is

reached.

WARNING

Not a Step!

Do not step on the enclosure (guard). It can collapse. You

can lose your balance and fall.

Death or serious injury can result.

FIGURE 7-10

Ten si o n

Idler

Crank

Shaft

Fan

Alternator

Water

Pump

Looking at Engine

from Fan End

FIGURE 7-11

Tension

Water Pump

Crank

Shaft

Idler -

No Fan

Option

Looking at Engine

from Fan End

Alternator

Loading...

Loading...