Manitowoc Published 09-10-14, Control # 065-24 2-13

14000 SERVICE MANUAL HYDRAULIC SYSTEM

SHOP PROCEDURES

Initial Oil Fill

The following procedure is used at the factory to fill the

hydraulic system on a new crane. It is necessary to use this

procedure in the field only if the entire hydraulic system has

been drained.

1. If equipped with free fall drums, fill front and rear drum

pump cases with oil as follows:

a. Disconnect hydraulic hose and remove fitting from

case drain port in top of both pumps.

b. Fill both pump cases to level of case drain port. Use

new hydraulic oil filtered through a 10-micron

filter.

c. Reinstall fittings and reconnect hydraulic lines.

2. Fill all motor cases with oil (Figure 2-13

).

a. Disconnect fittings at case drain ports.

b. Fill each motor case to level of case drain port. Use

new hydraulic oil filtered through a 10-micron

filter.

c. Reconnect fittings.

3. Open hydraulic tank shut off valve (7a, Figure 2-1

).

4. Open return line cap (8) in return line (Figure 2-1

).

5. Make sure drain valve (7, Figure 2-1

) is closed.

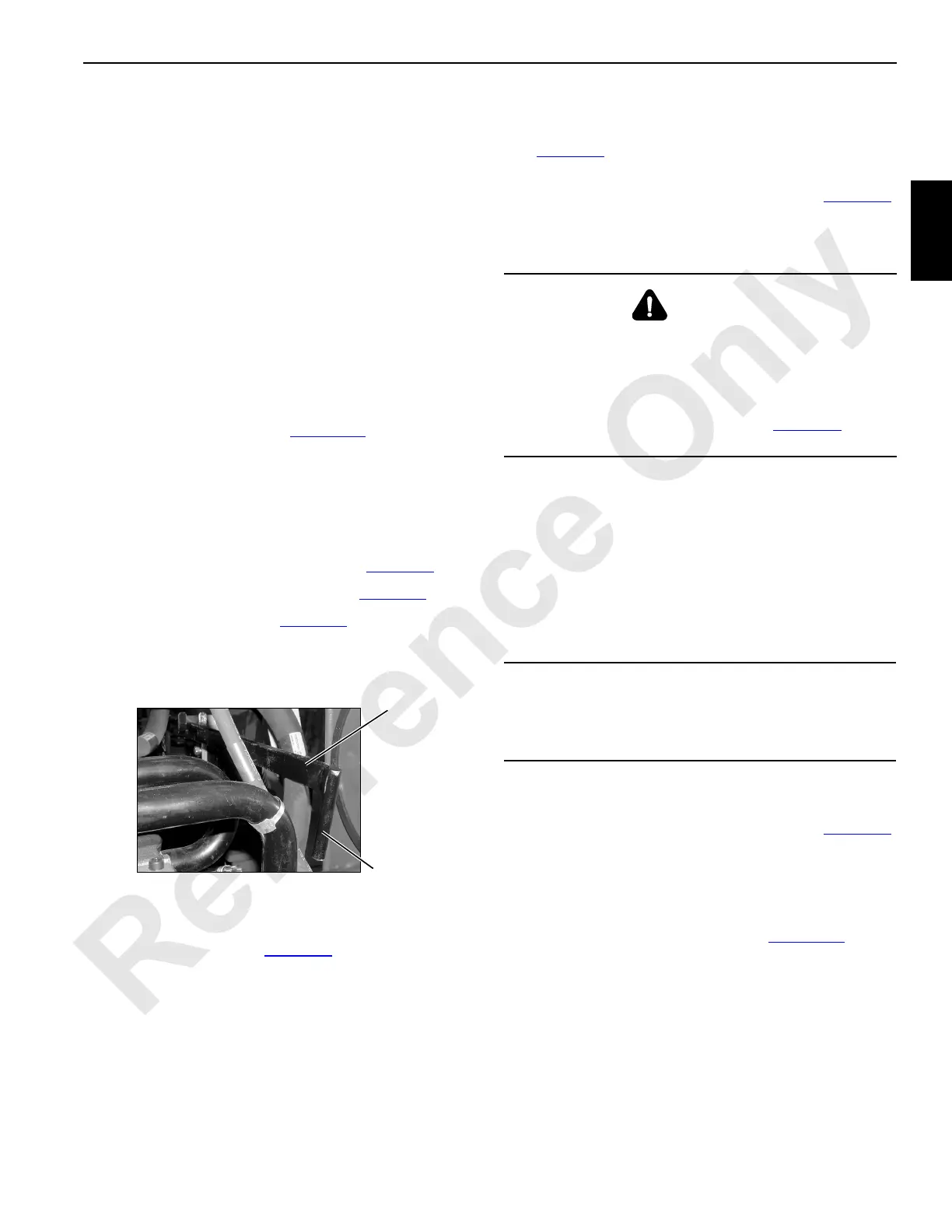

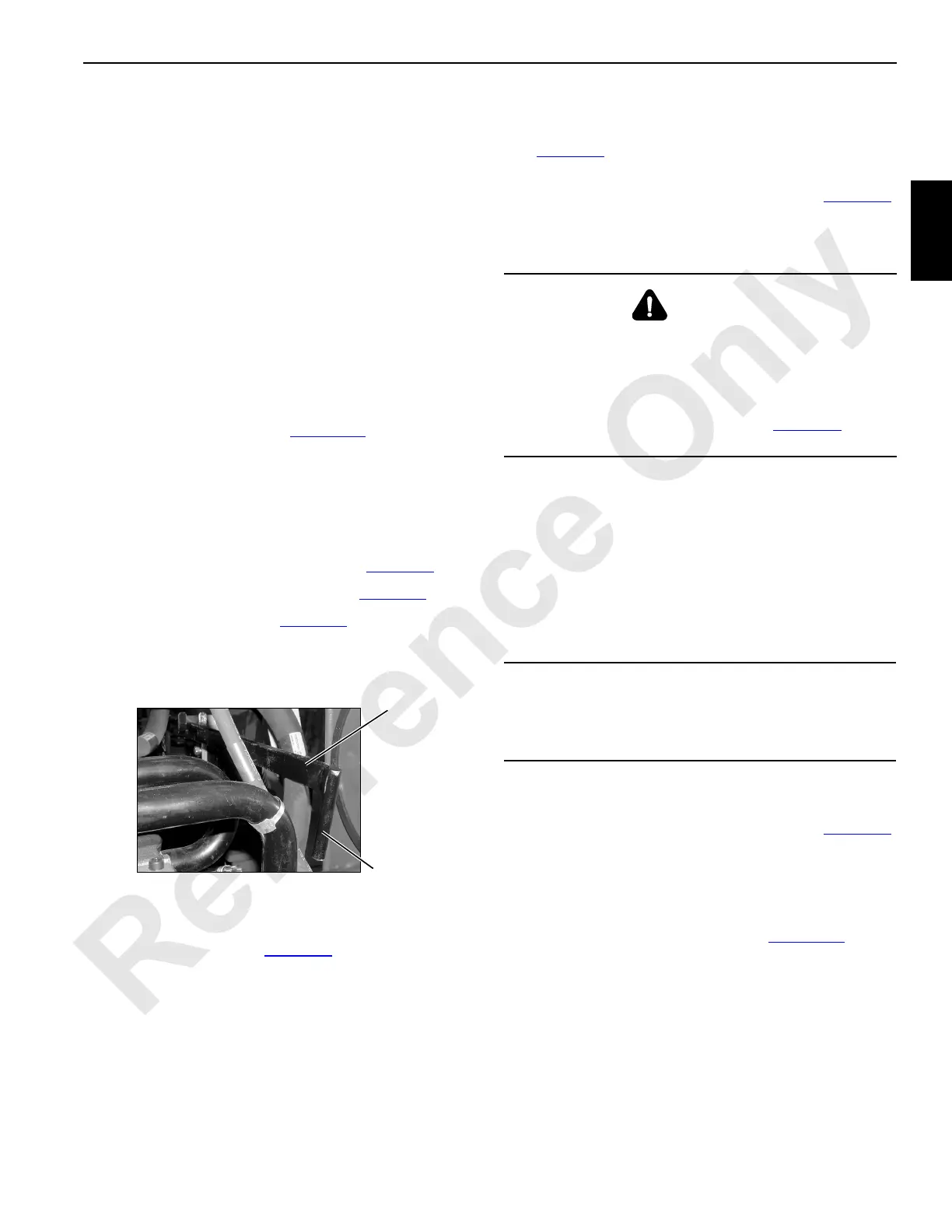

6. At the engine, disengage engine clutch (Figure 2-14).

7. Fill through stand pipe in return line (2a) or through

power fill coupling (2b, Figure 2-1

). Use new hydraulic

oil filtered through a 10-micron filter.

8. Open air valve (4) on top of tank to release pressure

when filling through power fill coupling.

9. Fill to Cold Full level (9) on hydraulic tank gauge.

10. Fill pump cases at return line cap (8) in return line

(Figure 2-1

) until manifold will not take any more oil. Use

new hydraulic oil filtered through a 10-micron filter.

11. Install and securely tighten return line cap (8, Figure 2-1

)

as soon as clear oil appears.

12. Check for hydraulic leaks and correct if found.

Initial Start-Up

The following procedure is used at the factory to start a new

crane engine for the first time. It is necessary to use this

procedure in the field only if the entire hydraulic system has

been drained.

The procedure requires two people: one to start the engine

and monitor pressures on the diagnostic screens and one to

monitor gauge pressure and check for leaks.

1. BEFORE starting the engine, calibrate pressure senders

as described in this section.

2. Make sure hydraulic tank shutoff valve (6a, Figure 2-1

)

is fully open. Pumps can be damaged from cavitation

if this step is not performed.

3. Disconnect electrical (DIN) connectors (5) from

solenoids.

4. At engine, disengage engine clutch (Figure 2-14

).

5. Start the engine at lowest possible speed and make

necessary adjustments before engaging clutch.

6. Slowly engage and disengage clutch and check for

charge pressure.

FIGURE 2-14

Left Side Enclosure

Lift Handle Up

and Push

In to Engaged

Disengaged

Position

Engine Clutch Lever

P2374

WARNING

Burn Hazard!

Oil in hydraulic tank may be under pressure and

extremely hot.

Hot oil can escape when you remove filter fill cap.

Relieve pressure through air valve (4, Figure 2-1

) in top

of tank before servicing.

CAUTION

Avoid Damage to Hydraulic System!

If hydraulic fluid low alarm comes on at any time during

start-up procedure, add oil to tank.

Loading...

Loading...