HYDRAULIC SYSTEM 14000 SERVICE MANUAL

2-14

Published 09-10-14, Control # 065-24

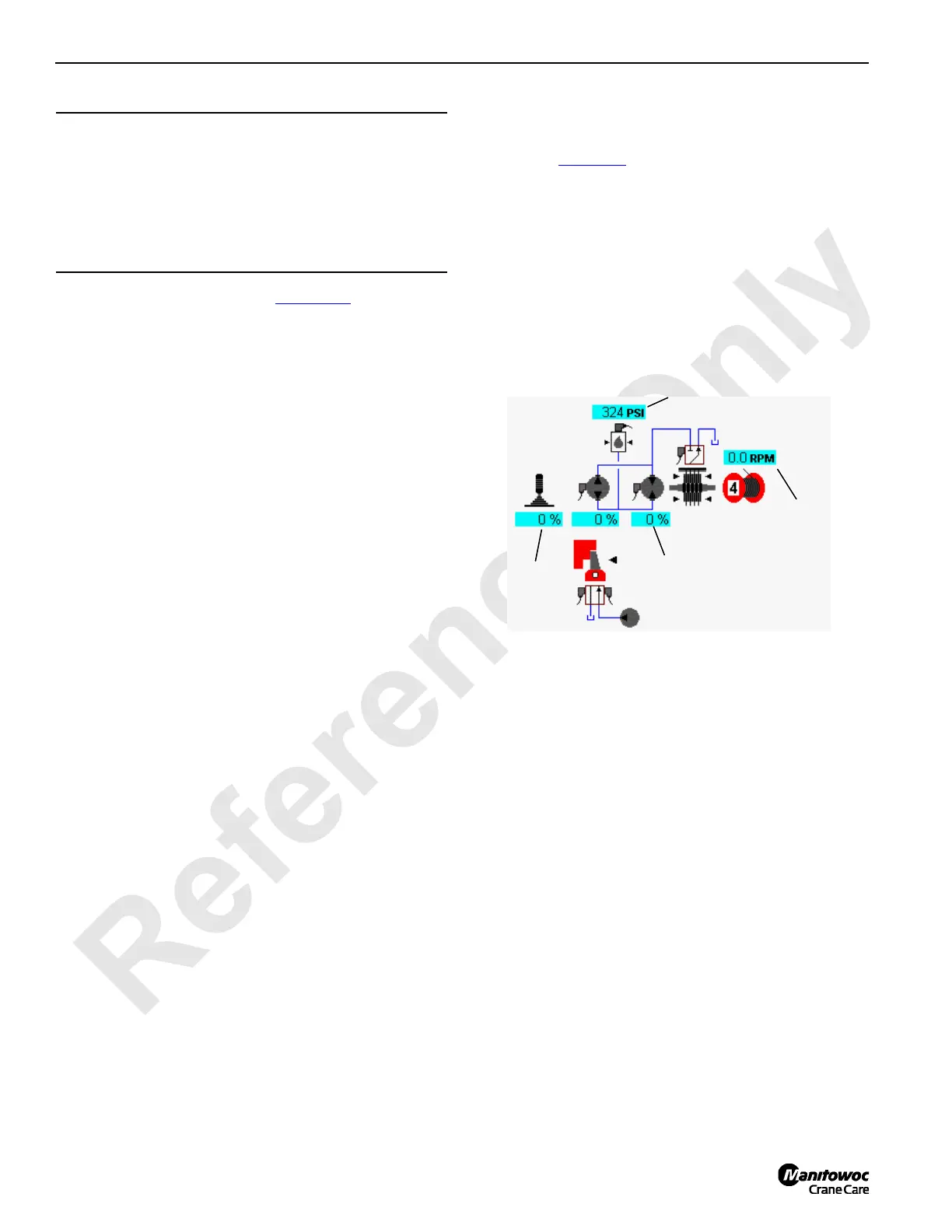

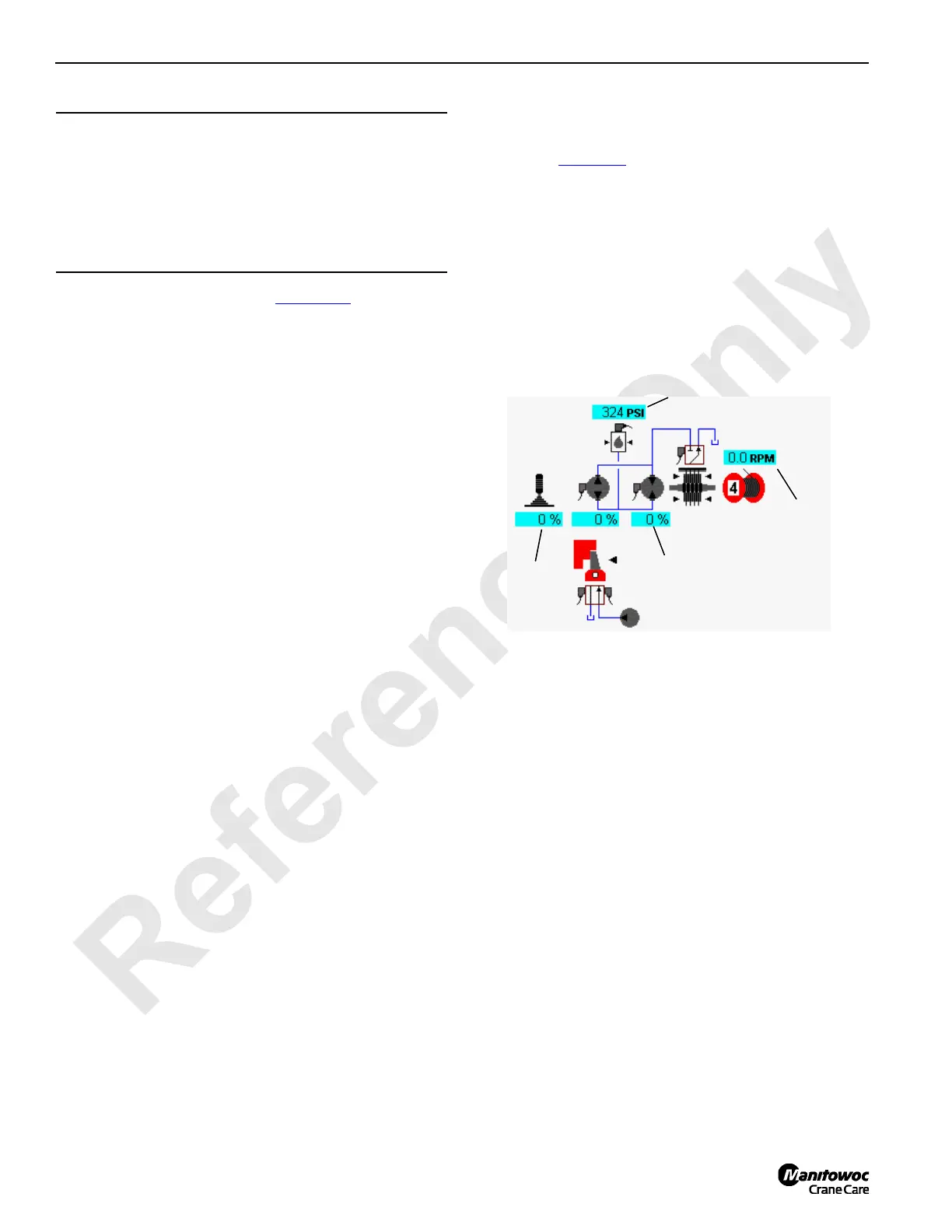

7. On diagnostic screens (see Figure 2-15), check pump

pressures for load drums, boom hoist, swing, and travel

pumps:

a. Make sure pressure reading for each pump is 250 to

370 psi (22 to 25,5 bar).

b. If pump pressures are not within specified range,

stop the engine immediately. Determine cause of

faulty pressure and correct.

8. Stop the engine.

9. Reconnect electrical (DIN) connectors removed in step

3.

10. Start and run the engine at low idle.

11. With the engine at low idle, extend and retract all

cylinders three times: gantry cylinders, mast cylinders,

back hitch pins, cab tilt, boom hinge pin, carbody jacks,

and crawler pins.

If oil level drops to 50%, a fault alarm will come on and a

fault symbol will appear on the active display.

HYDRAULIC FLUID LOW icon will appear on fault

display (Figure 2-2

). Fill tank immediately.

12. With the engine running at low idle, slowly cycle each

crane function in both directions for at least five minutes

to vent any remaining air from hydraulic system.

13. Be sure all crane functions operate in proper direction

with relation to control handle movement.

14. Check for hydraulic leaks and correct cause if found.

15. Stop the engine and fill hydraulic tank to proper level.

16. Perform System Calibration and Test in this section.

CAUTION

Equipment Damage!

Check pump pressures during first two minutes of

operation. If pressure for any pump is not within specified

range, shut down the engine immediately to prevent

pump damage. Troubleshoot to determine cause of

problem.

FIGURE 2-15

Typical Diagnostic Screen

(Screen for Drum 4 Shown)

Handle

Command

Drum

Speed

System

Pressure

Pump

Command

14COM3-34

Loading...

Loading...