Manitowoc Published 09-10-14, Control # 065-24 5-13

14000 SERVICE MANUAL HOISTS

Wear and Other Damage

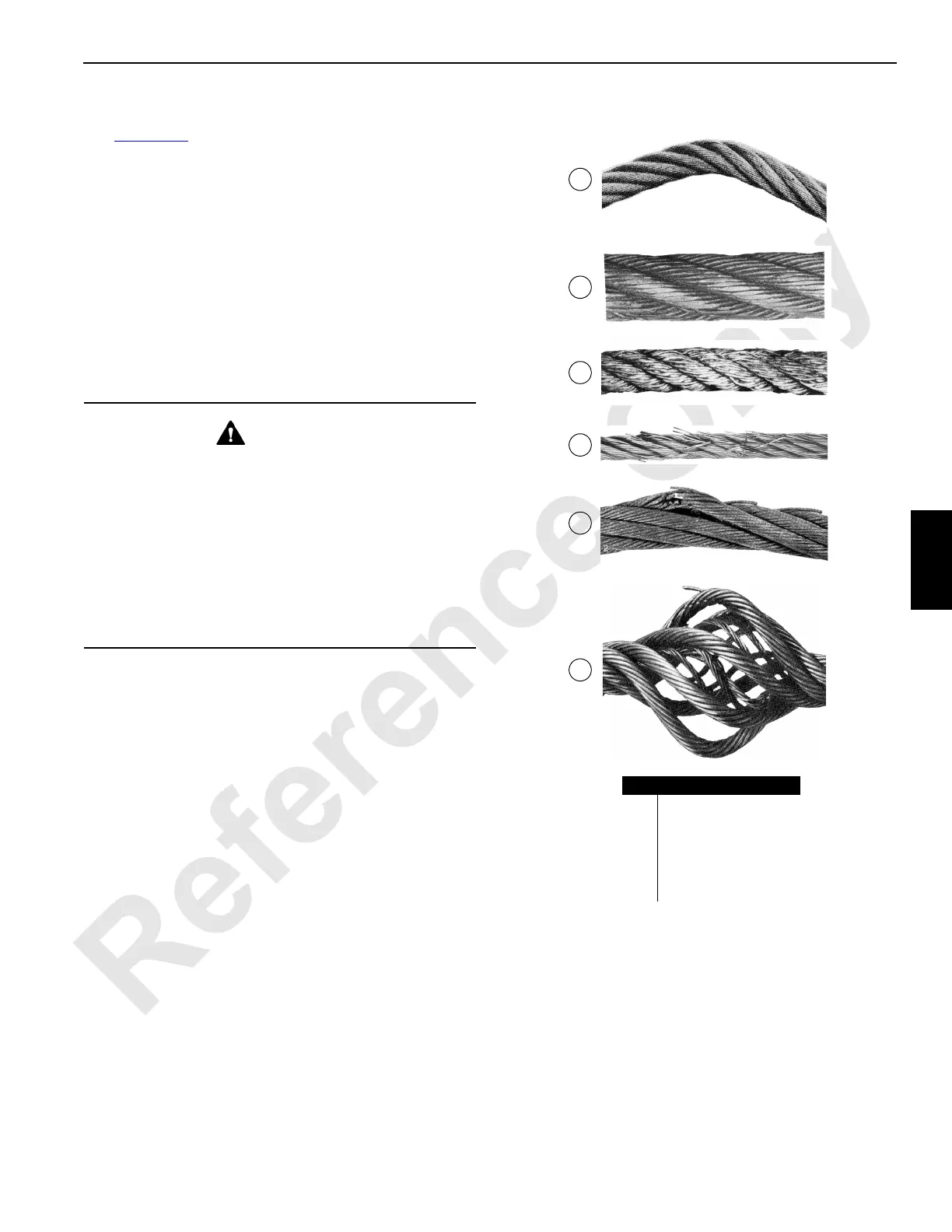

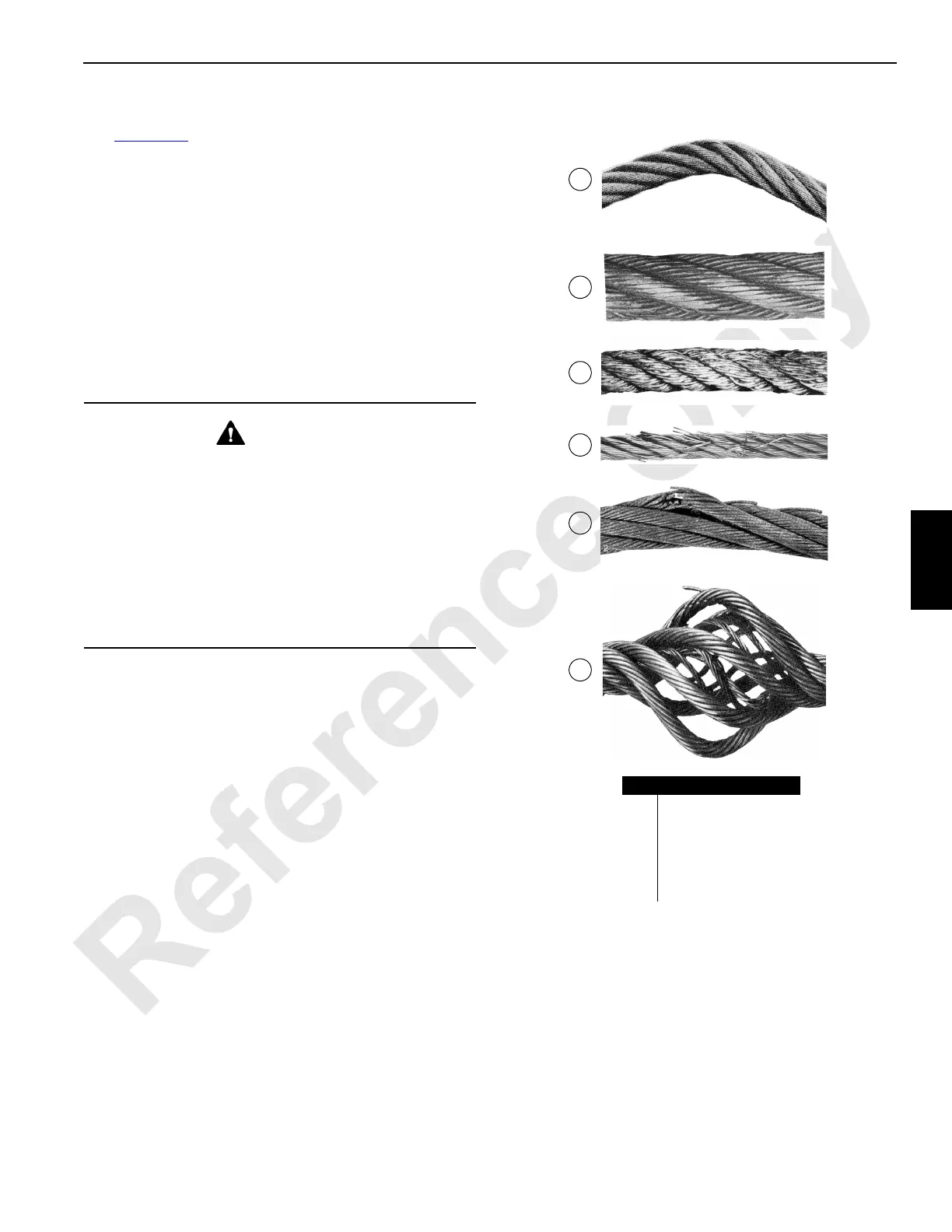

See Figure 5-11 for examples of wire rope damage.

It is normal for the outer wires of the rope to wear first

because of friction.

The wire rope must be taken out of service if:

• Rope core protrudes from between outer strands

• Severe corrosion – indicated by pitting – exists

• Obvious damage exists from any heat source to include

– but not limited to – welding, power line strike, or

lighting.

• Kinking, crushing, bird caging, or any other damage

resulting in distortion of the rope structure exists.

DISTRIBUTING WIRE ROPE WEAR

Wire rope wear at the “critical wear points” can be reduced

and the life of the wire rope extended by moving the rope at

regular intervals so different sections of rope are subjected to

the wear points. This practice can also help correct spooling

problems and rope vibration.

To move the wire rope, cut off a piece of wire rope at the

drum and refasten it. The piece cut off should be long

enough to move wire rope at least one full drum wrap.

If the wire rope is too short to allow cutting off a piece of it,

reverse the rope end for end and refasten it.

WARNING

Falling Load Hazard!

Replacement wire rope can break if does not meet

Manitowoc specifications given in the following

publications supplied with your crane:

• Wire Rope Specifications Chart located in Capacity

Chart Manual (for load lines)

• Boom or Jib Assembly Drawings located in Crane

Operator Manual (for boom or luffing hoist)

• Mast Assembly Drawing located in Parts Manual

FIGURE 5-11

Item Description

1 Dog-Leg or Kink

2 Drum Abrasion

3 Drum Crushing

4 Sheaves Too Small

5 Button Socket

6 Bird Cage

1

2

3

4

5

6

M100655a-f

Loading...

Loading...