HOISTS 14000 SERVICE MANUAL

5-14

Published 09-10-14, Control # 065-24

SHEAVE, ROLLER, AND DRUM INSPECTION

Perform the following inspections WEEKLY.

1. Check the drum clutches and brakes for proper

adjustment.

2. Check all sheaves, rollers, and drums for the following

conditions:

a. Unusual noises

b. Freedom of movement — must turn freely by hand.

Wire rope may have to be loosened to perform this

inspection.

c. Wobble — must turn true with very little side-to-side

or up-and-down play

d. Signs of rust (indicating that water may have

entered bearing).

e. Grease leaks (indicating a faulty seal or water in

grease)

The above problems indicate bearing damage. If found,

the corresponding sheave, roller, or drum should be

disassembled for further inspection. New bearings

should be installed.

For sheaves not equipped with grease fittings, be sure to

pack new bearings with grease at assembly.

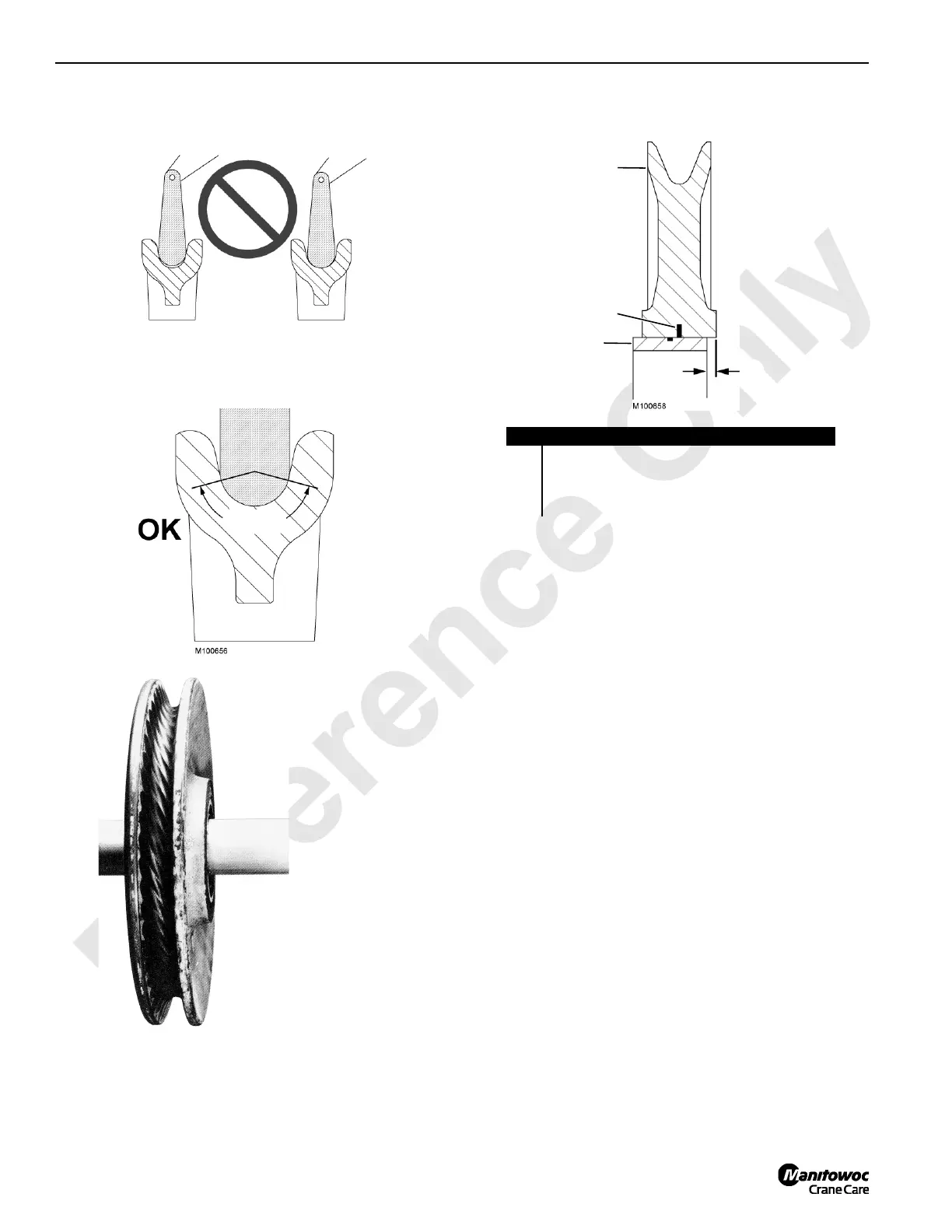

FIGURE 5-12

Observe groove to see if contour of gauge

matches contour at bottom of sheave groove.

Proper fitting sheave groove should support wire

rope or 135–150° of rope circumference.

Groove Too Small

Groove Too Large

135°–150°

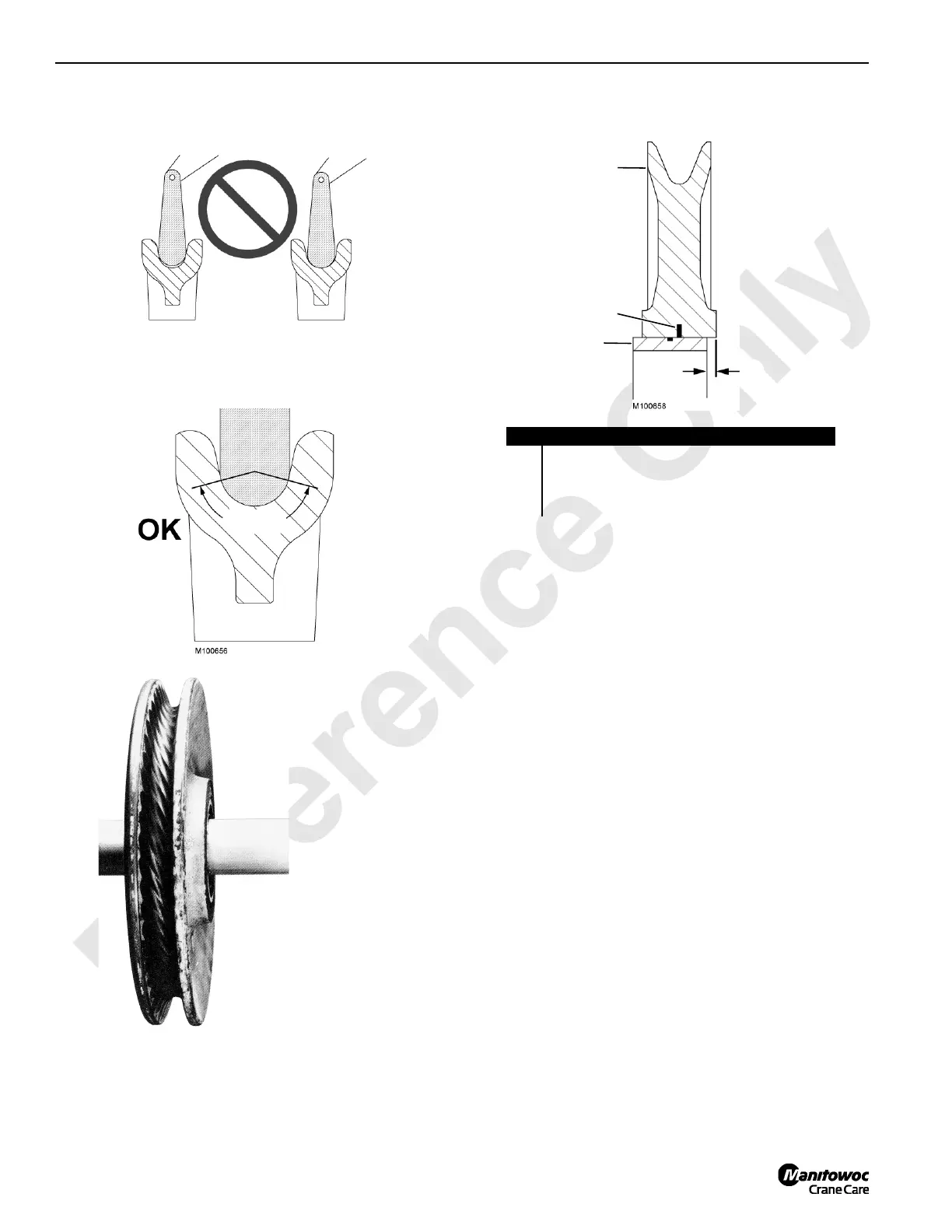

FIGURE 5-13

“Corrugated” steel sheave,

roller, or drum will cause

wire rope to wear rapidly.

FIGURE 5-14

Item Description

1 Nylon Sheave

2 Improper Snap Ring Engagement

3 Steel Insert of Bearing

4 1/8 in (3 mm) Maximum Sideways Displacement

1

3

2

4

Loading...

Loading...