2202MYJE-MY-C8-N_2018.02.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 3225**C 2.3 Compressor Specifications

2-2

2.3 Compressor Specifications

2.3.1 Standard Specifications

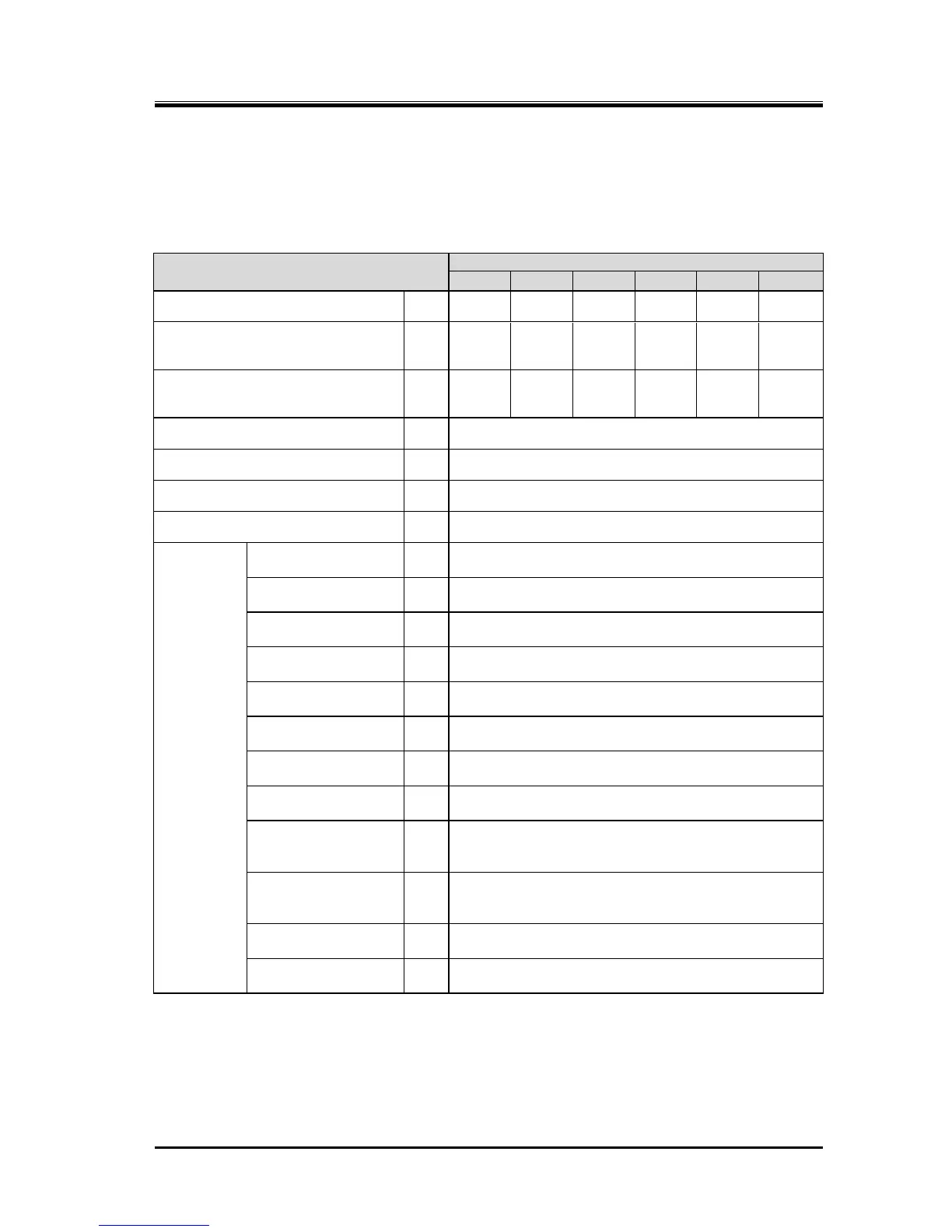

Table 2-1 3225**C Screw Compressor Specifications (1/2)

Low-stage swept volume

@3550 min

-1

/2950 min

-1

High-stage swept volume

@3550 min

-1

/2950 min

-1

Working fluid (Refrigerant)

Ammonia, Hydrofluorocarbon, etc.

Capacity control (Actual load)

Counterclockwise viewed from motor

Low-stage discharge

flange

High-stage suction

flange

High-stage discharge

flange

Journal lubrication

(low-stage)

Journal lubrication

(High-stage)

Oil injection

lubrication

Oil return Inlet

(Rotor casing)

Oil return outlet

(Low-stage Bearing

cover)

Oil return outlet

(High-stage Suction

cover)

Low-stage capacity

control

Load: Rc3/8, Unload: Rc3/8

High-stage capacity

control

Load: Rc3/8・Rc1/2, Unload: Rc3/8

Unless otherwise noted, the pressure unit MPa represents the gauge pressure

in this manual.

For limits of working temperature and pressure, see "2.3.2 Operation Limits" in

this manual.