2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.4 Disassembly and Inspection

5-21

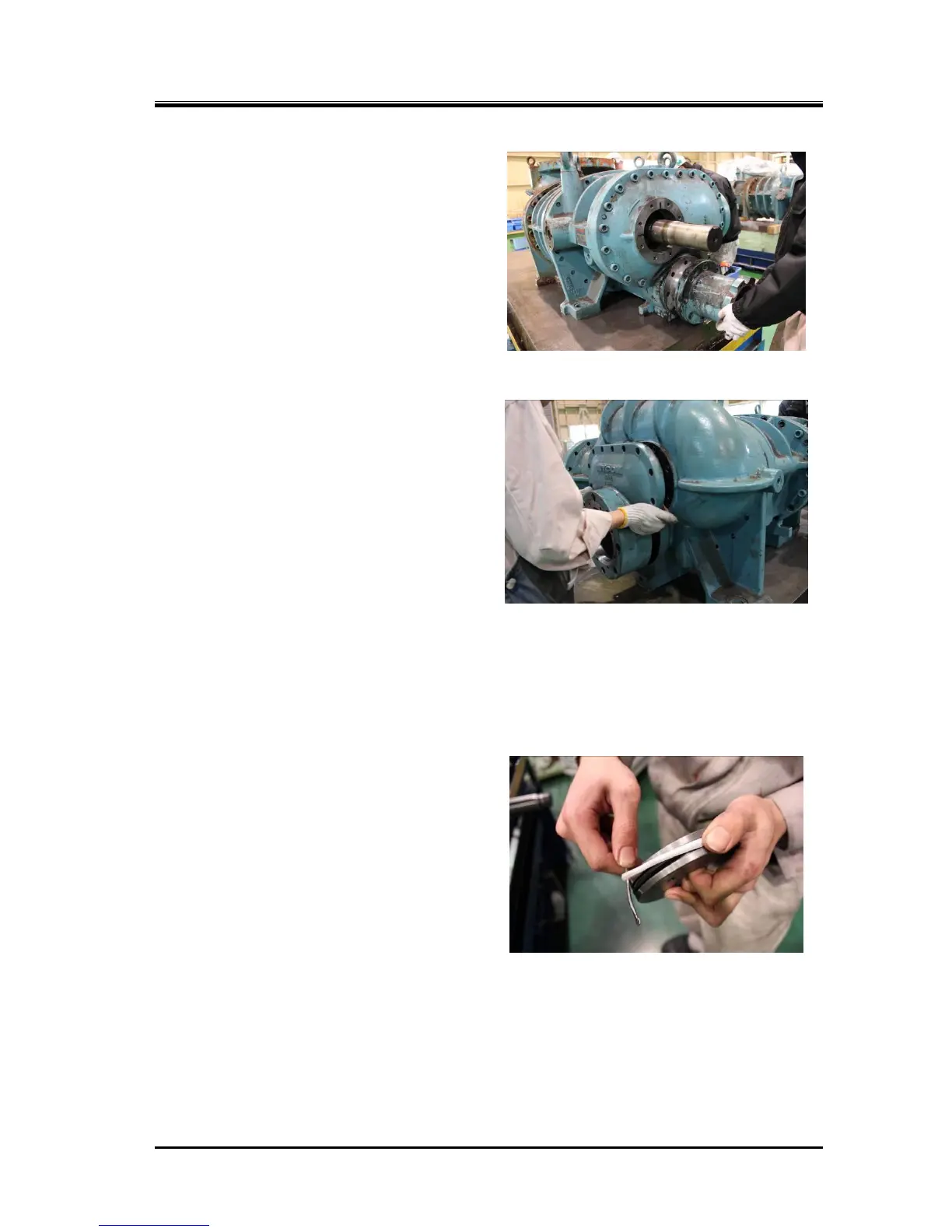

b) The low-stage unloader cylinder [60-1] is

fastened by eight long hexagon socket head

cap screws [62-1] to the low-stage bearing

head [11-1] together with the bearing cover

[16].

Even when all the hexagon socket head cap

screws are removed, the unloader cylinder will

not drop off as it is securely engaged with the

bearing cover. Pull out the unloader cylinder

by holding the flange or rib.

c) The high-stage unloader cylinder [60-2] is also

fastened by hexagon socket head cap screws

[61] (× 2) and [62-2] (× 6). The high-stage

unloader cylinder is to be pulled out similarly

to Step b) for the case of low-stage cylinder.

However, if the cylinder is to be further

disassembled, leave the two bolts [61]

fastened. Remove the bolts [24] and [62-2]

fastening the balance piston cover [22] and

remove the unloader cylinder together with

the balance piston cover. In this, as oil

remains in the balance piston and side

bearing part, be careful of the oil that will

come out when the balance piston cover is

removed. If the gasket [23] is sticking and it

does not come off, screw in two M8 eye bolts

to the two forcing screw threads on the

balance piston cover to separate the gasket.

5.4.3.2 Inspection

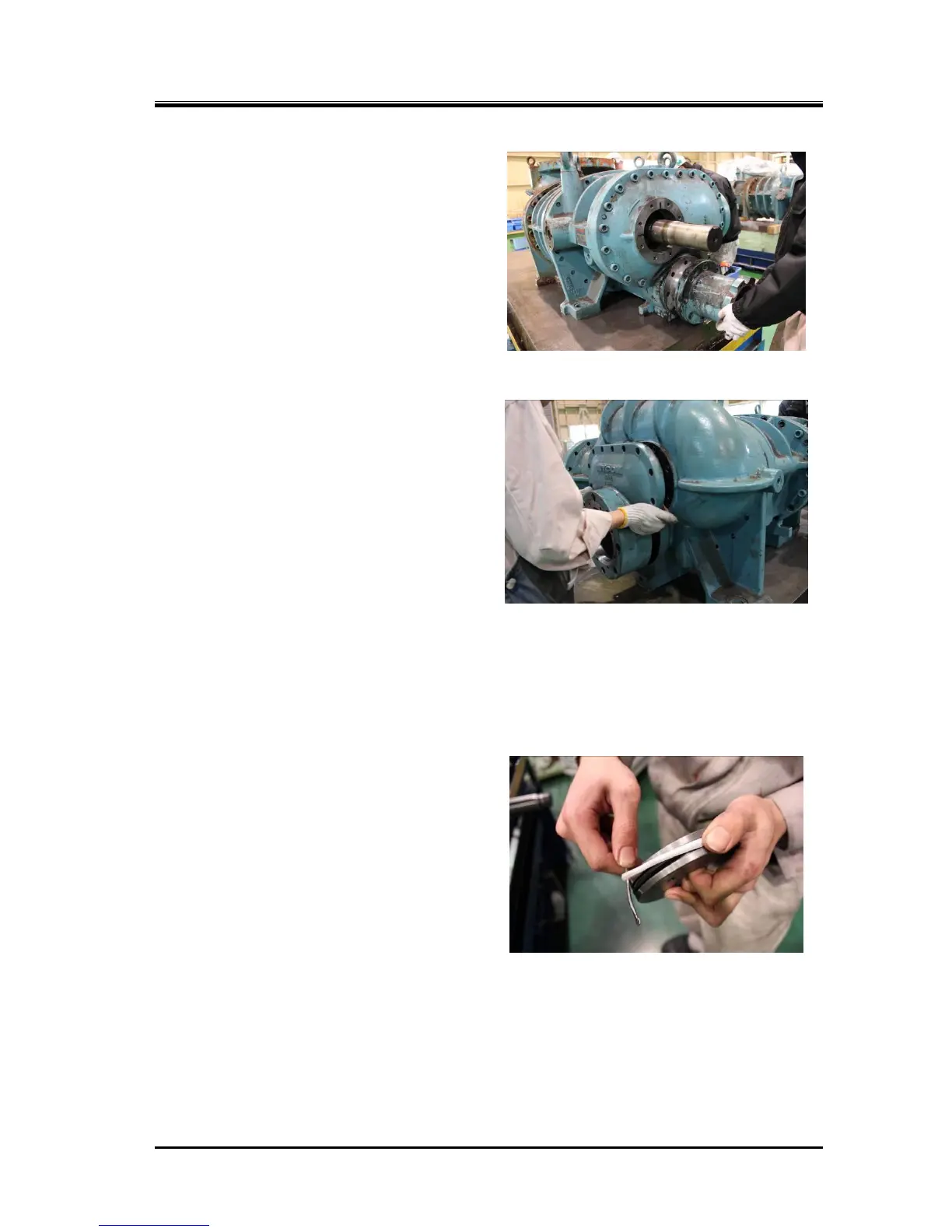

a) Both the O-ring [65-1] [65-2] and cap seal

[64-1] [64-2] that are on the periphery of the

unloader piston [64-1] [64-2] must be replaced

by new ones.

b) As it is often seen that the inside of the

unloader cylinder has flaws or is contaminated

by oil residue, thoroughly clean the area and

use fine sandpapers to finish the surface.

Loading...

Loading...