2202MYJE-MY-C8-N_2018.02.

Chapter 4 Operation of Compressor and Unit

Compound 2-stage Screw Compressor 3225**C 4.2 Precautions for Operation

4-7

4.2 Precautions for Operation

If the package unit is used in the refrigeration cycle, please keep in mind the contents of this section in

particular.

4.2.1 Prevention of Liquid Flow-back Operation

Liquid flow-back is a phenomenon where refrigerant that did not completely evaporate with the gas

reaches the compressor. Liquid flow-back may cause insufficient lubrication of the compressor,

abnormal vibrations and noises, and abnormal foaming of lubricating oil (too much oil loss). To prevent

liquid flow-back, properly adjust the expansion valve of each liquid cooler.

For details, refer to Chapter 6 "Troubleshooting" in this manual Chapter 6.

4.2.2 Purging of Non-Condensable Gases

Some types of refrigerants emit bad smells or toxic gases. Make sure to ventilate the

air during work.

When handling fluorocarbon refrigerants, remember that they are prohibited from

being purged into air by law.

If there is a leak on the low-pressure side of the system, air may enter the package unit.

If non-condensable gas like air enters the package unit, the condensing pressure rises and the energy

consumption increases. This leads to uneconomical operation.

Follow the procedure below to check for non-condensable gases.

1. When the compressor is stopped, allow the cooling water to flow to the unit's condenser for at

least 15 minutes. Check the condensing pressure by using the pressure gauge of the compressor.

2. Check the cooling water temperature.

3. Compare the condensing pressure checked in step 1 above with the refrigerant saturation

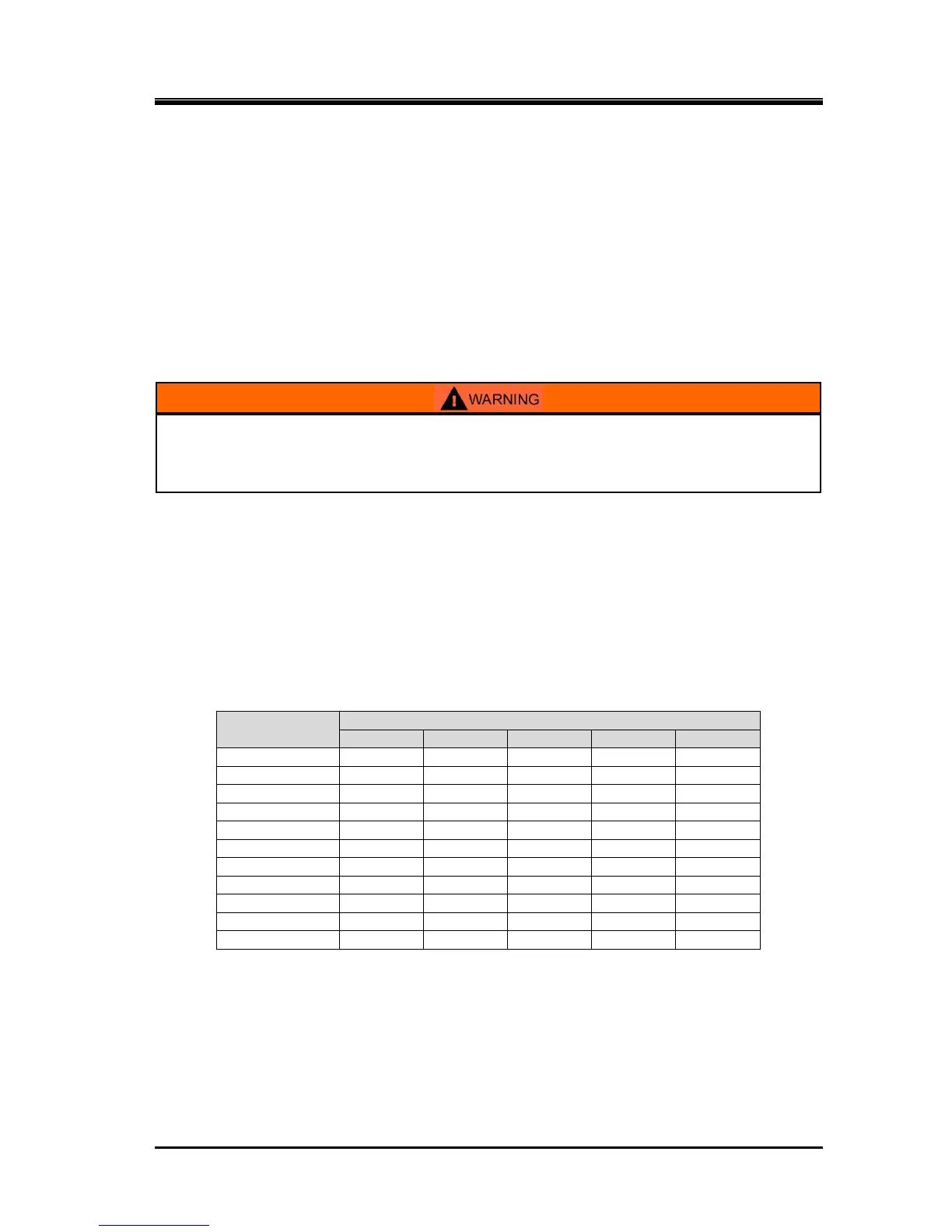

pressure that depends on the cooling water temperature (as shown in the table below).

Table 4-4 Typical Refrigerant Temperature and Saturation Pressure

■ Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

4. When the pressure inside the condenser and the refrigerant saturation pressure that depends on

the cooling water temperature are approximately equivalent, non-condensable gases do not exist.

When the pressure inside the condenser is 0.05 MPa or more higher than the refrigerant

saturation pressure that depends on the cooling water temperature, there is a possibility of

non-condensable gases entering the unit. In that case, purge the non-condensable gases from

the condenser.

Loading...

Loading...