2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.4 Disassembly and Inspection

5-26

5.4.7.2 Inspection

Check the hub and sleeve for possible deformation of the gear teeth and wear on each tooth flank.

If it is found abnormal, replace the whole gear coupling assembly. At the same time, investigate the

cause of the abnormality.

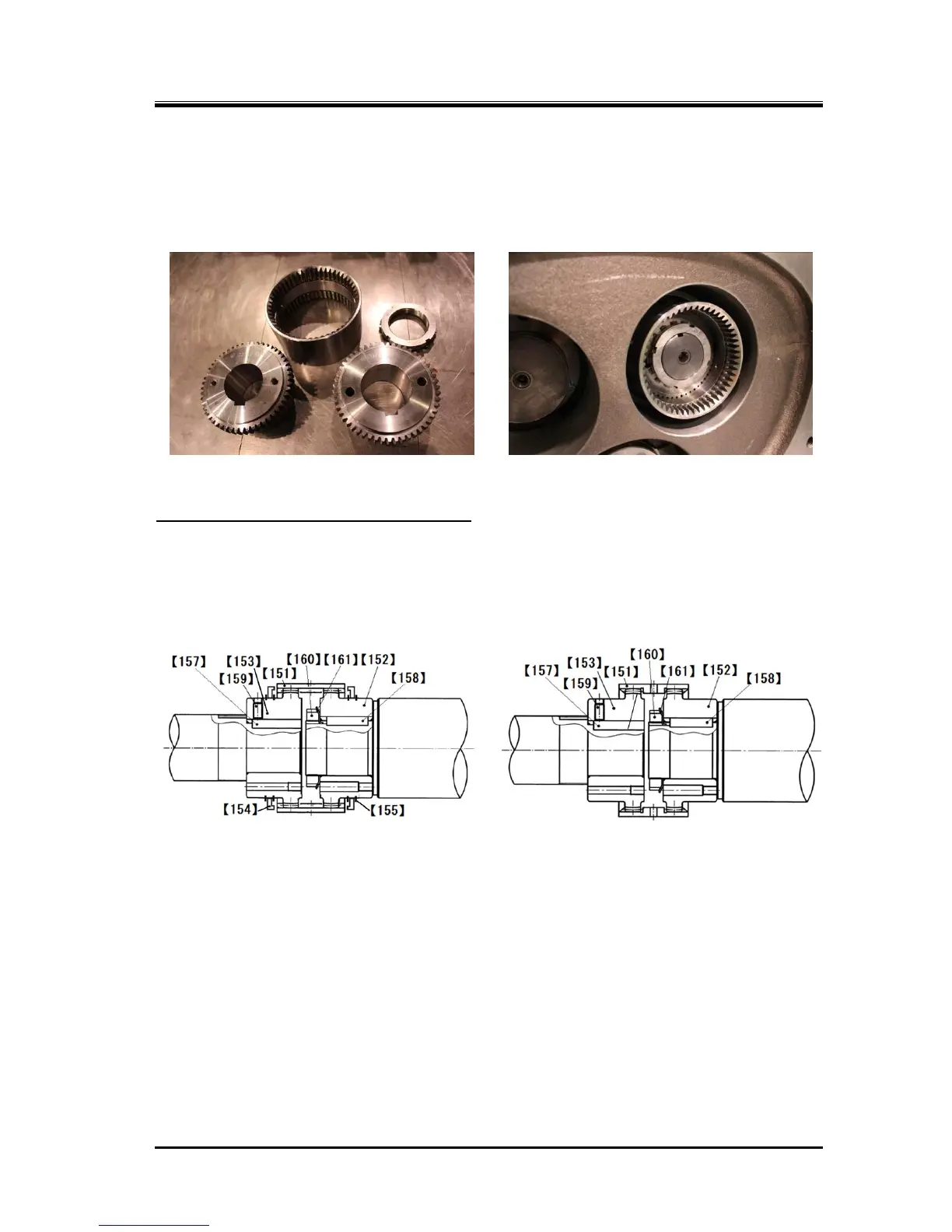

Photo 027: Current Gear coupling parts

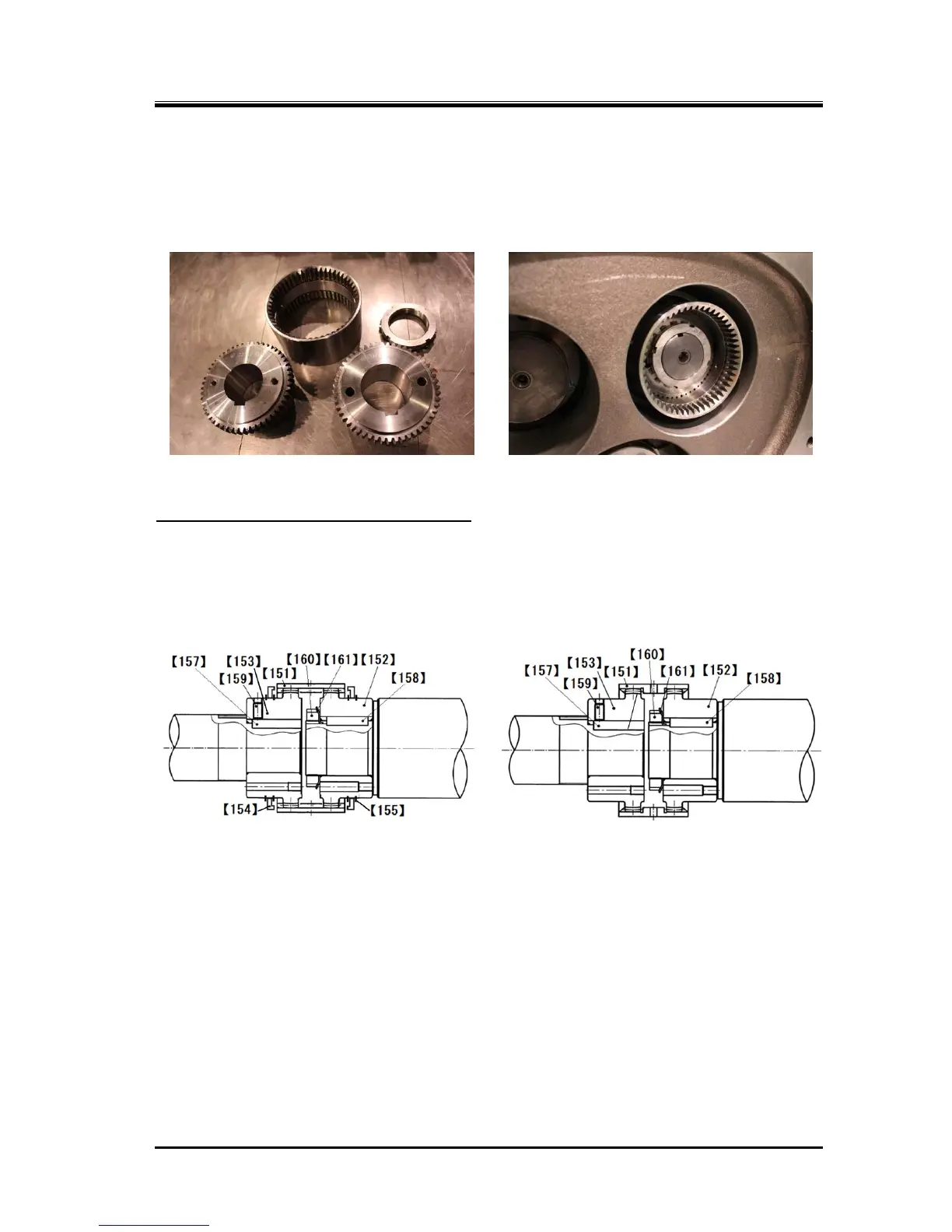

Photo 028: Low-stage Gear Coupling

Gear coupling mechanism of 3225**C models

The gear coupling of 3225**C uses a coupling hub and drive sleeve. While the old couplings (before the

design modification made in February 2011) have a stop on both outer ends of the sleeve to prevent the

sleeve from dropping off, the stops are placed on the inside of the drive sleeve after the design

modification (compatible with the old type).

After this design modification, the drive sleeve stopper [154] and stop ring [155] are no more used.

The gear coupling assembly consists of the items

151, 152, 153, 154*2, 155*4, and 159.

The gear coupling assembly consists of the

items151, 152, 153, and 159.

Figure 5-8 Conventional Method (Before the

Design modification in Feb. 2011)

Figure 5-9 New Method (After the Design

modification in Feb. 2011)

Loading...

Loading...