2202MYJE-MY-C8-N_2018.02.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 3225**C 5.4 Disassembly and Inspection

5-15

5.4.1 Unloader Indicator

Because the type 3225**C has a capacity control mechanism also on the high-stage, there are two

unloader indicator locations. The standard operation method is such that the capacity control is used

only on the low-stage during operation, and the capacity control on the high-stage is used to reduce the

load during the startup phase.

As a different control method may be used depending on the system, refer to the separate electrical

control schematic diagram for the plant.

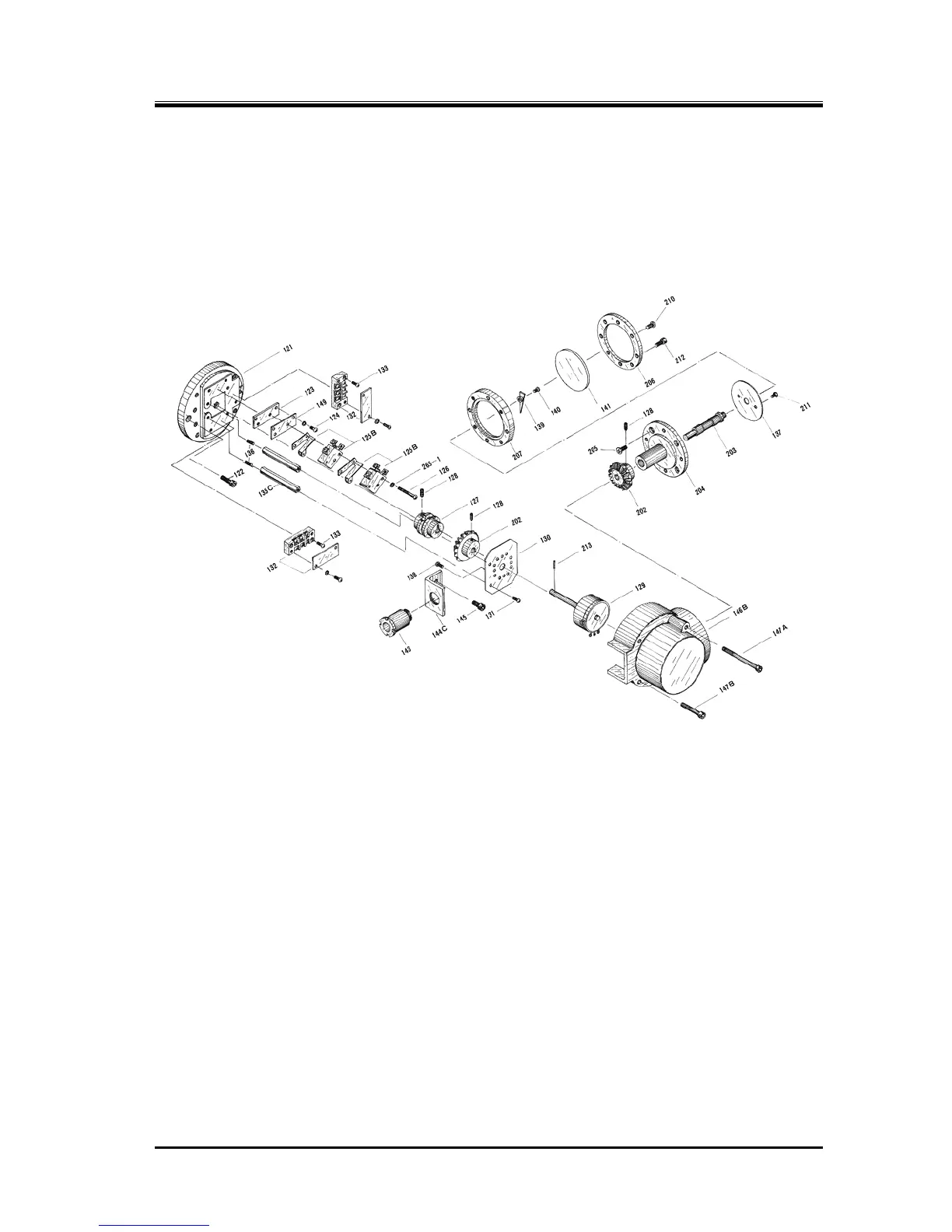

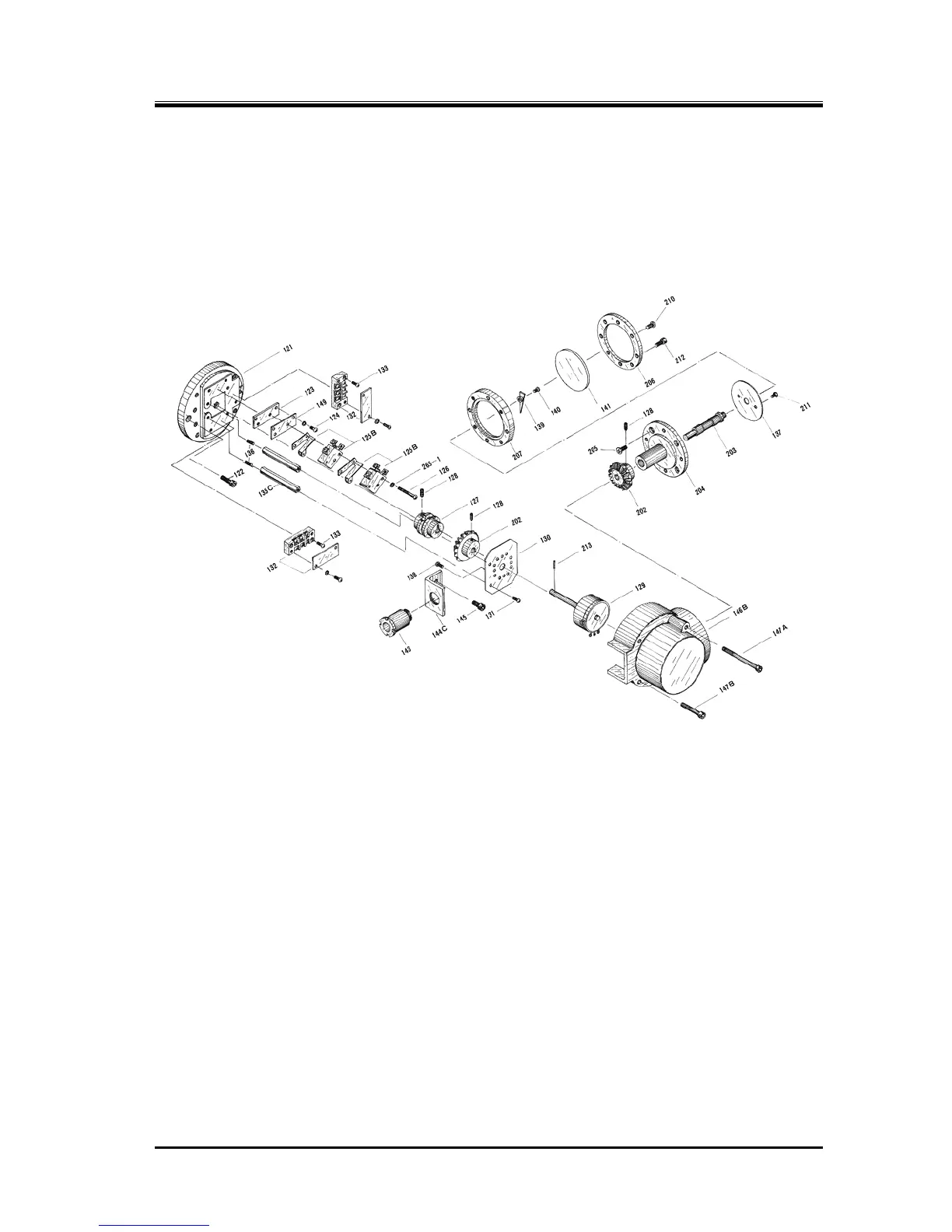

Figure 5-2 Exploded View of the Standard Low-stage Indicator for 3225**C

5.4.1.1 Disassembly

■ In Case of Removing the Wiring only

When removing the wiring of the unloader indicator upon removing the compressor, it is necessary

to remove the cover as the indicator has a terminal block for the wiring. Perform the work according

to the following procedure, and after removing the wires, attach the cover to them for protection.

○ Low-stage

a) Loosen the hexagon socket head cap screws [212] that are fastening the indicator glass [141]. In

this, do not loosen the Phillips screws [210] on the same surface. In this way, the assembly

consisting of the parts [141], [202 to 207], [210], and [211] can be removed.

b) By removing the two each hexagon socket head cap screws [147A] and [147B] that are used to

fasten the indicator cover [146B], the cover can be removed.

c) As you can see the terminal block, remove the plastic cover on the block, and then remove the

screws to disconnect the wires.

Loading...

Loading...