13NIBE F1330

Installation / Adjustment

Pipe connections

Filling and venting the collector system

The brine circuit must be supplied with a pressure expan-

sion vessel. If there is a level vessel this should be replaced.

The brine side should be pressurised to at least 0.5 bar.

The pressure expansion vessel should be dimensioned as

set out in the diagram, to prevent operating disturbances.

The pressure expansion vessel covers the temperature

range from -10 °C to +20 °C at a pre-pressure of 0.5 bar

and the safety valve’s opening pressure 3 bar.

To fill the collector system, mix antifreeze with water in an

open container which connect with filling pump and hoses

as illustrated. The brine should be protected from freezing

down till -15 °C.

Q The valve on the main pipe between service connec-

tions is closed.

Q To fill, start the pump in the filling vessel and allow it to

run until the fluid comes back in the return hose.

Q The fluid can circulate via the mixing vessel until fluid,

without air, returns to the return hose.

Q Stop the filling pump and clean the particle filter. Start

the filling pump again.

Q Open the valve on the main pipe between the service

branches while the filling pump is still operational (to

release the air between the branches).

Q Close the valve on the return hose.

Q Pressurise the system (to max 3 bar) with the filling

pump.

Q Close the filling valve and stop the filling pump.

Internal venting valves

Filling the heating medium system

The heating medium system is filled with water until the

required pressure is reached and then vented.

Readjusting, heating medium side (75)

Air is initially released from the hot water and venting

may be necessary. If bubbling sounds can be heard from

the heat pump, the entire system requires further vent-

ing. When the system has stabilised (correct pressure and

all the air removed) the heating controls can be set at the

required value.

Readjusting, brine side (77)

Check that all air is removed from the collector system

by opening the venting valves. The pressure in the brine

circuit is checked with the help of pressure gauges. Filling

of collector system is done by pumping ready mixed brine

through the filling valve.

Venting and filling are repeated until all the air has been

removed and the correct pressure (0.5 - 3 bar) has been

obtained.

AV Shutoff valve

BK Rock collector

EXP Level vessel

JK Soil collector

KB-in Brine in

KB-ut Brine out

KBP Brine pump

SF Particle filter

B

A

A B I II

50.0 C

Varmvattentemperatur

13.43

1.0

A B

BK / JK

KBP

VBP-B

VVR

VVF

VBFB

VBRA/VBRB

KBut

KB-in

VBFA

AV

VBP-A

SF

EXP

P

*

* The brine pump for 60 kW is supplied and installed externally out-

side the heat pump..

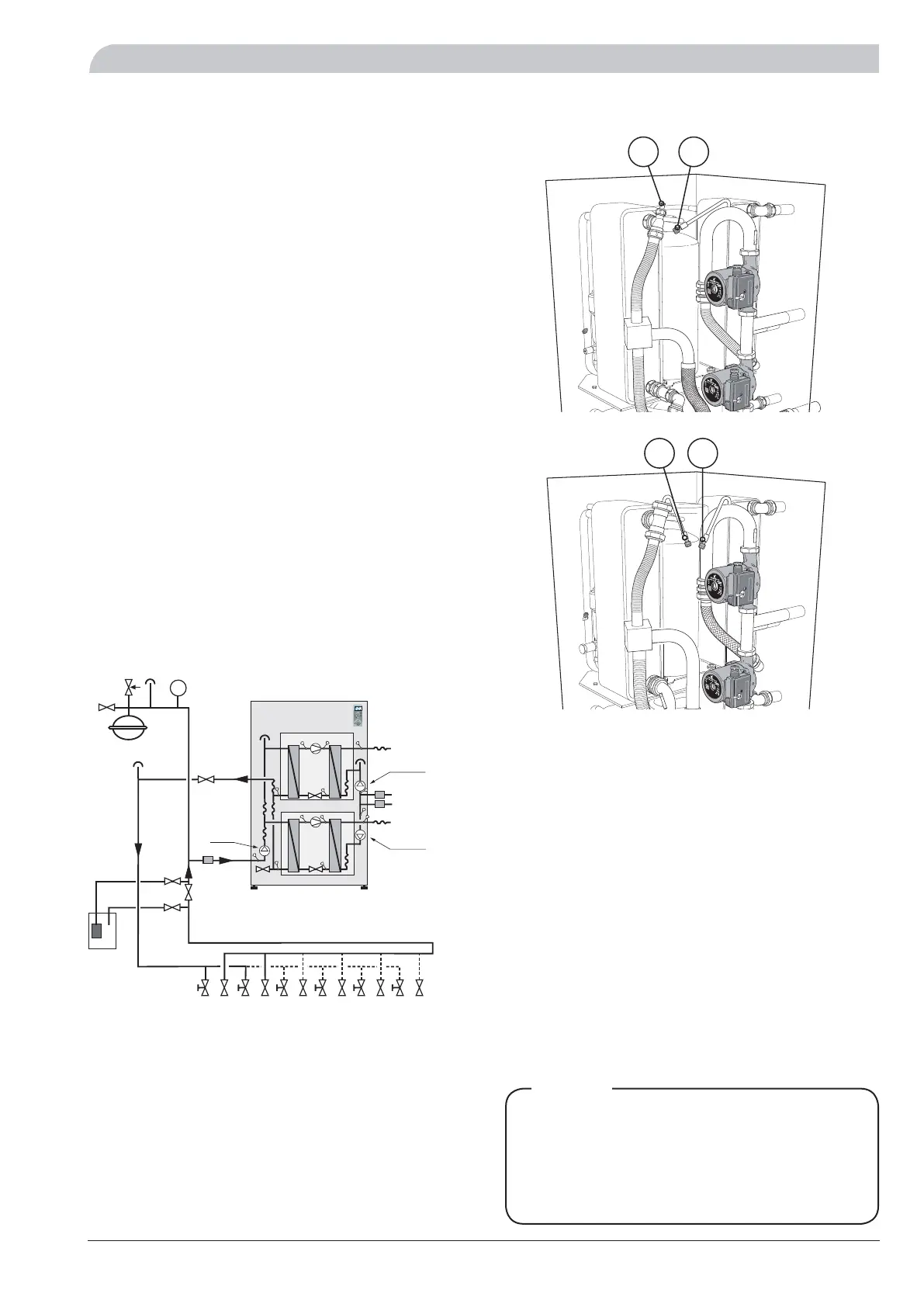

F1330 22-40 kW

75

77

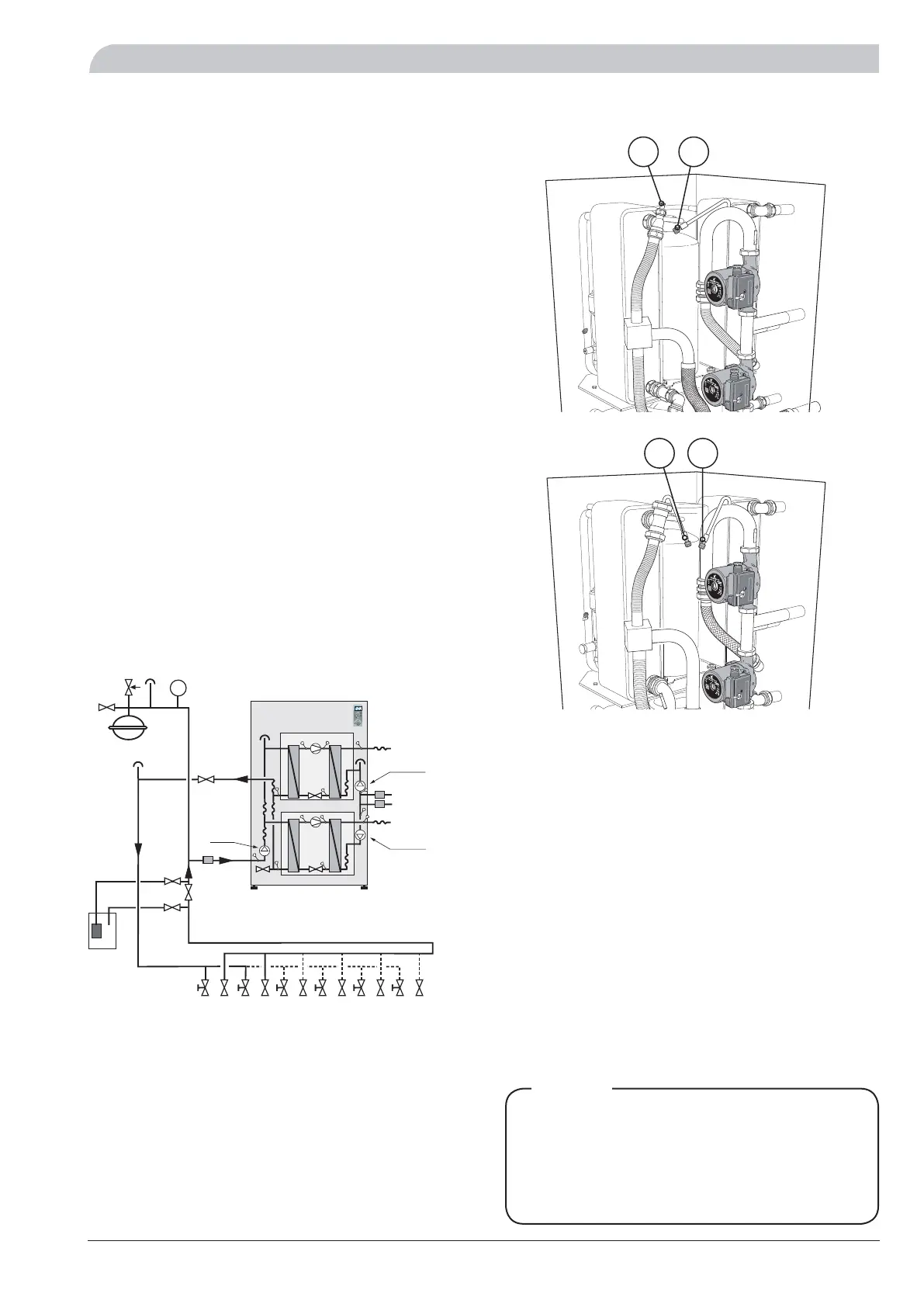

F1330 60 kW

77

75

To access and change the speed of the

brine pump (22-40 kW) the circulation

pump’s distribution box must be opened.

The speed is set to ”3” (maximum speed)

upon delivery.

NOTE!

Loading...

Loading...