60

Determining PID Constants (AT, ST, Manual Setup) Section 3-8

3-8 Determining PID Constants (AT, ST, Manual Setup)

3-8-1 AT (Auto-tuning)

• When AT is executed, the optimum PID constants for the set point at that

time are set automatically. A method (called the limit cycle method) for

forcibly changing the manipulated variable and finding the characteristics

of the control object is employed.

• Either 40% AT or 100% AT can be selected depending on the width of MV

variation in the limit cycle. In the AT Execute/Cancel parameter, specify

at-2 (100% AT) or at-1 (40% AT). To cancel AT, specify off (AT can-

cel).

• Only 100% AT can be executed for heating and cooling control or for float-

ing control for position-proportional models.

• AT cannot be executed when control has stopped or during ON/OFF con-

trol.

• The results of AT are reflected in the Proportional Band (P), Integral Time

(I), and Derivative Time (D) parameters for the PID set at the time AT exe-

cution starts. For details on PID sets, refer to PID Sets on page 129.

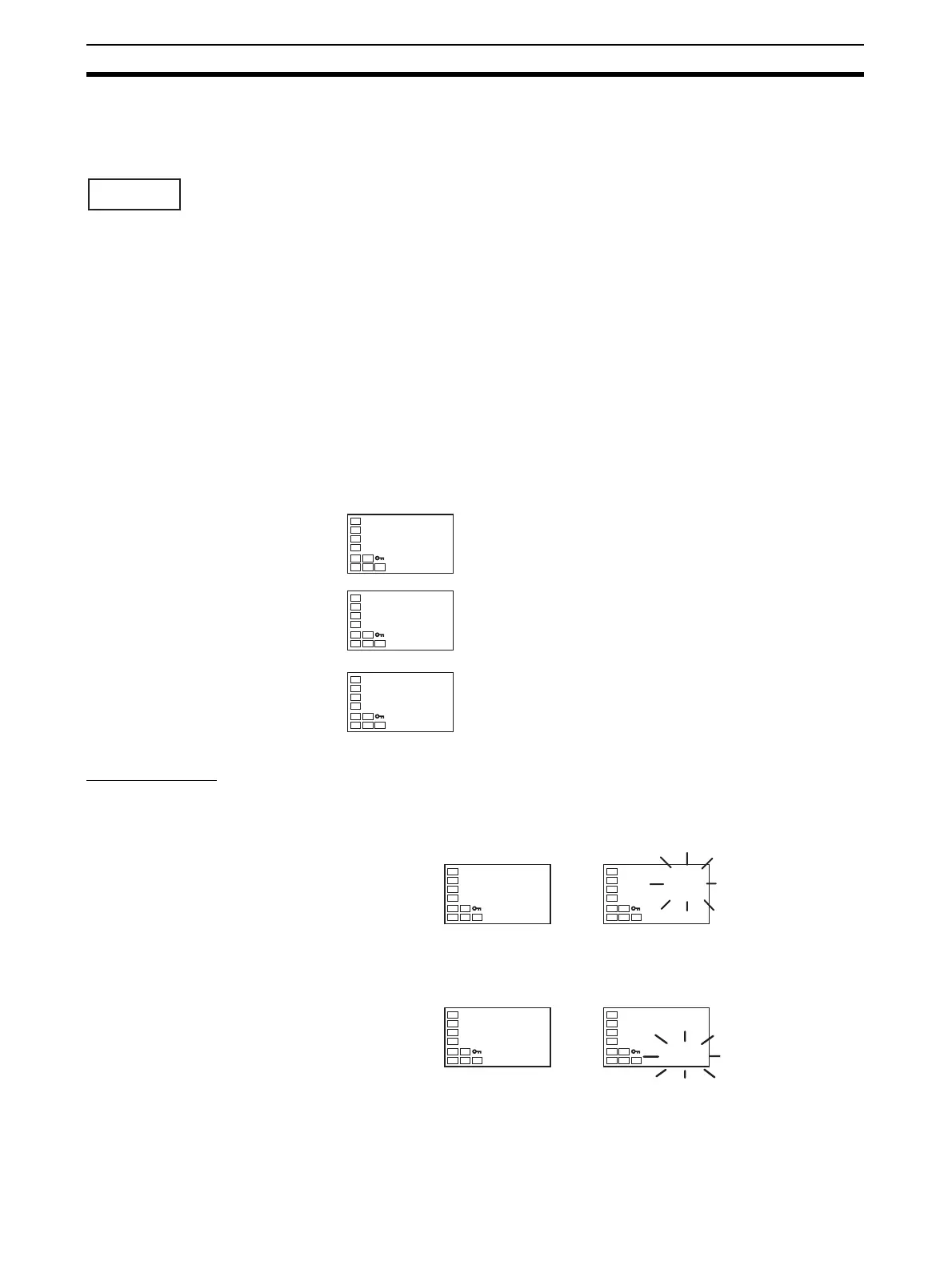

AT Operations AT is started when either at-2 (100% AT) or at-1 (40% AT) is specified for

the AT Execute/Cancel parameter. During execution, the AT Execute/Cancel

parameter on the No. 1 display flashes. When AT ends, the AT Execute/Can-

cel parameter turns OFF, and the No. 1 display stops flashing.

If you move to the operation level during AT execution, the No. 2 display

flashes to indicate that AT is being executed.

Only the Communications Writing, RUN/STOP, AT Execution/Cancel, and Pro-

gram Start parameters can be changed during AT execution. Other parame-

ters cannot be changed.

at

∗

.i

233.0

C

∗

.p

(0

∗

.d

40.0

PID Setting Level

PID* Proportional Band

PID* Integral Time

PID* Derivative Time

(

∗

: 1 to 8)

at

off

at

at-2

AT Execute/Cancel

No. 1 displa

100% AT execution in progress

C

25.0

100.0

C

25.0

100.0

PV/SP

AT execution in progress

No. 2 display

Loading...

Loading...