12.7 H: TERMINALS

730 SIEPYEUOQ2A01A AC Drive Q2A Technical Manual

■ H5-27 Mbus 5A Reg3 Selection

No.

(Hex.)

Name Description

Default

(Range)

H5-27

(158B)

RUN

Mbus 5A Reg3 Selection

Returns the contents of the specified Modbus communications register when responding to the

master device.

0042H (U1-03)

(0000H - FFFFH)

■ H5-28 Mbus 5A Reg4 Selection

No.

(Hex.)

Name Description

Default

(Range)

H5-28

(158C)

RUN

Mbus 5A Reg4 Selection

Returns the contents of the specified Modbus communications register when responding to the

master device.

0049H (U1-10)

(0000H - FFFFH)

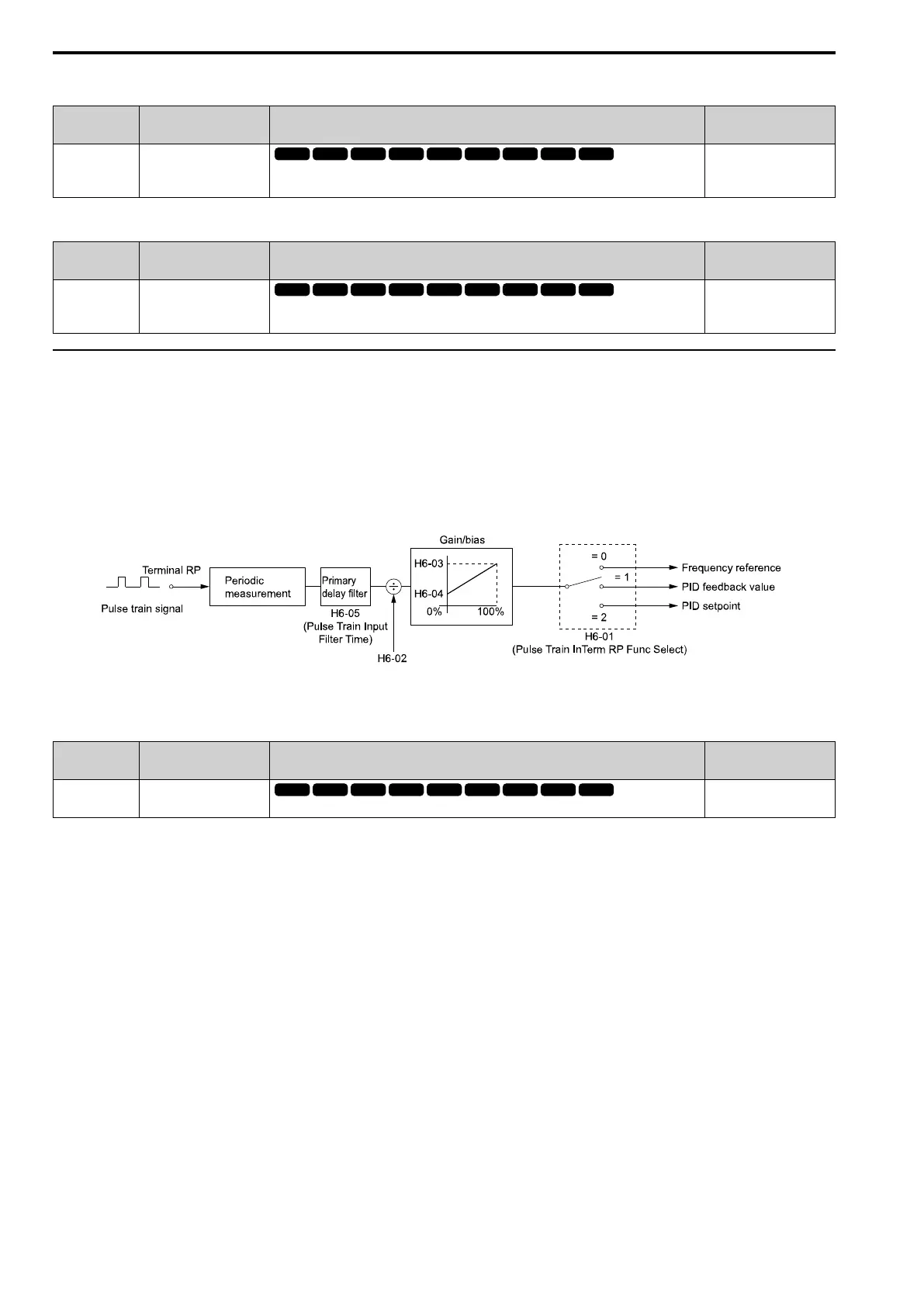

◆ H6: PULSE INPUT OUTPUT

H6 parameters set the drive pulse train input and pulse train monitor. These parameters select input and monitor

parameters and adjust the pulse train frequency.

A pulse train signal with a maximum single pulse of 32 kHz can be input to the drive input terminal PI. You can

use the pulse train signal as the frequency reference, PID feedback value, PID setpoint value, and speed feedback

for V/f Control mode.

A pulse train signal with a maximum frequency of 32 kHz can be output from the drive output terminal PO as the

monitor value. Sinking mode and sourcing mode are supported.

Figure 12.110 Pulse Train Input Block Diagram

■ H6-01 PI Pulse Train Function

No.

(Hex.)

Name Description

Default

(Range)

H6-01

(042C)

PI Pulse Train Function

Sets the function for pulse train input terminal RP.

0

(0 - 3)

0 : Freq Ref

When b1-01 [Freq. Ref. Sel. 1] or b1-15 [Freq. Ref. Sel. 2] = 4 [Pulse Train Input], the drive inputs the frequency

reference received from terminal RP.

1 : PIDFbk Value

The drive inputs the PID control feedback value received from terminal PI.

2 : PID SP Value

The drive inputs the PID control target value received from terminal PI.

3 : PG Feedback

Select V/f Control method to enable simple encoder feedback.

Use motor speed feedback for better speed control precision. The drive compares the frequency reference to the

motor speed feedback received from the encoder, and uses the ASR function to compensates for motor slip. You

cannot use input terminal RP used for the simple encoder to detect the direction of motor rotation. Use a different

method to detect motor rotation.

Use these methods to detect the direction of motor rotation.

• Use DI

Set DI H1-xx = 15 [FWD/REV Det]. When the configured terminal is activated, the motor operates in Reverse

run. When the terminal is deactivated, the motor operates in Forward run.

Use an encoder that outputs 2-tracks (phase A, B) to detect the direction of motor rotation.

Loading...

Loading...