2-2 Product Overview

AC10 Inverter

2.2 Control Features

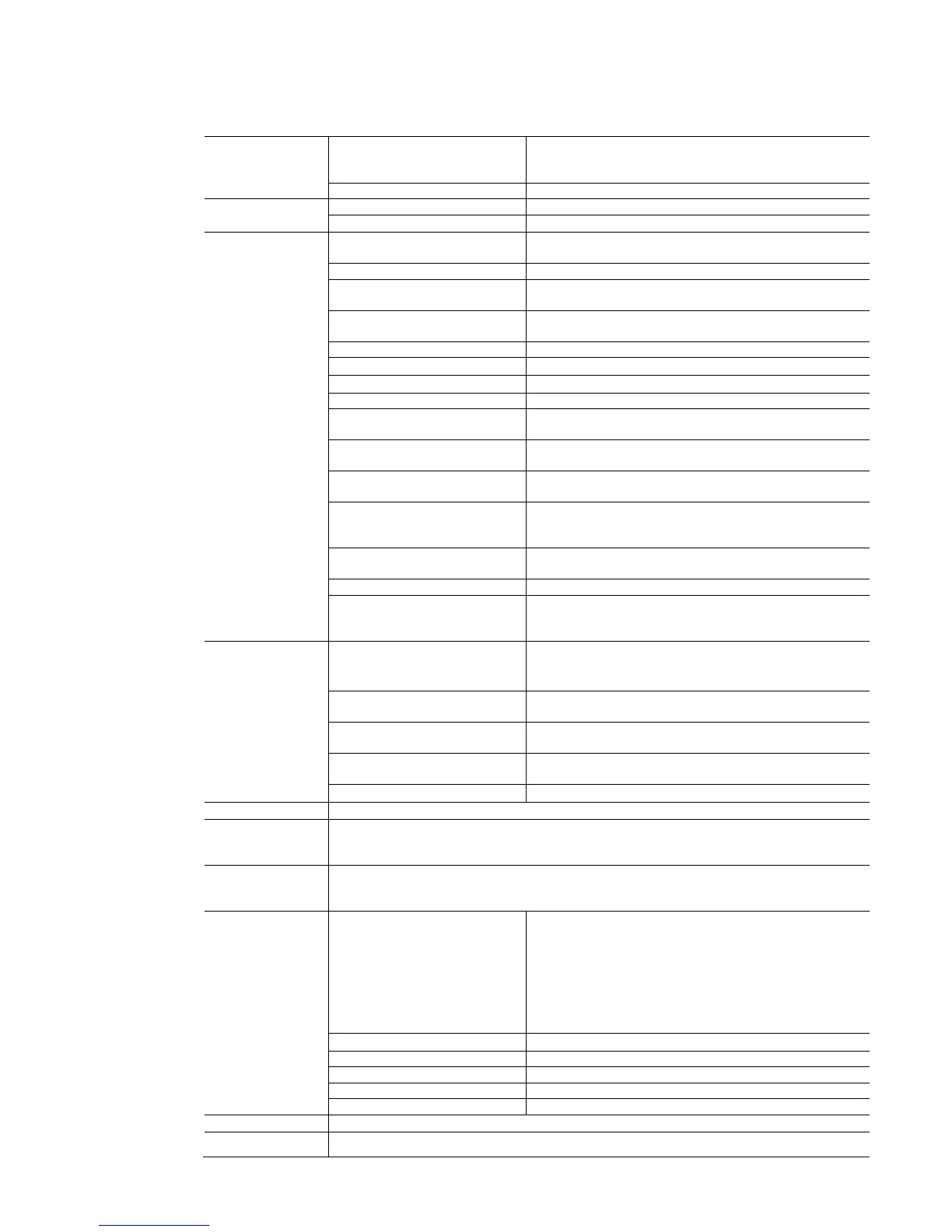

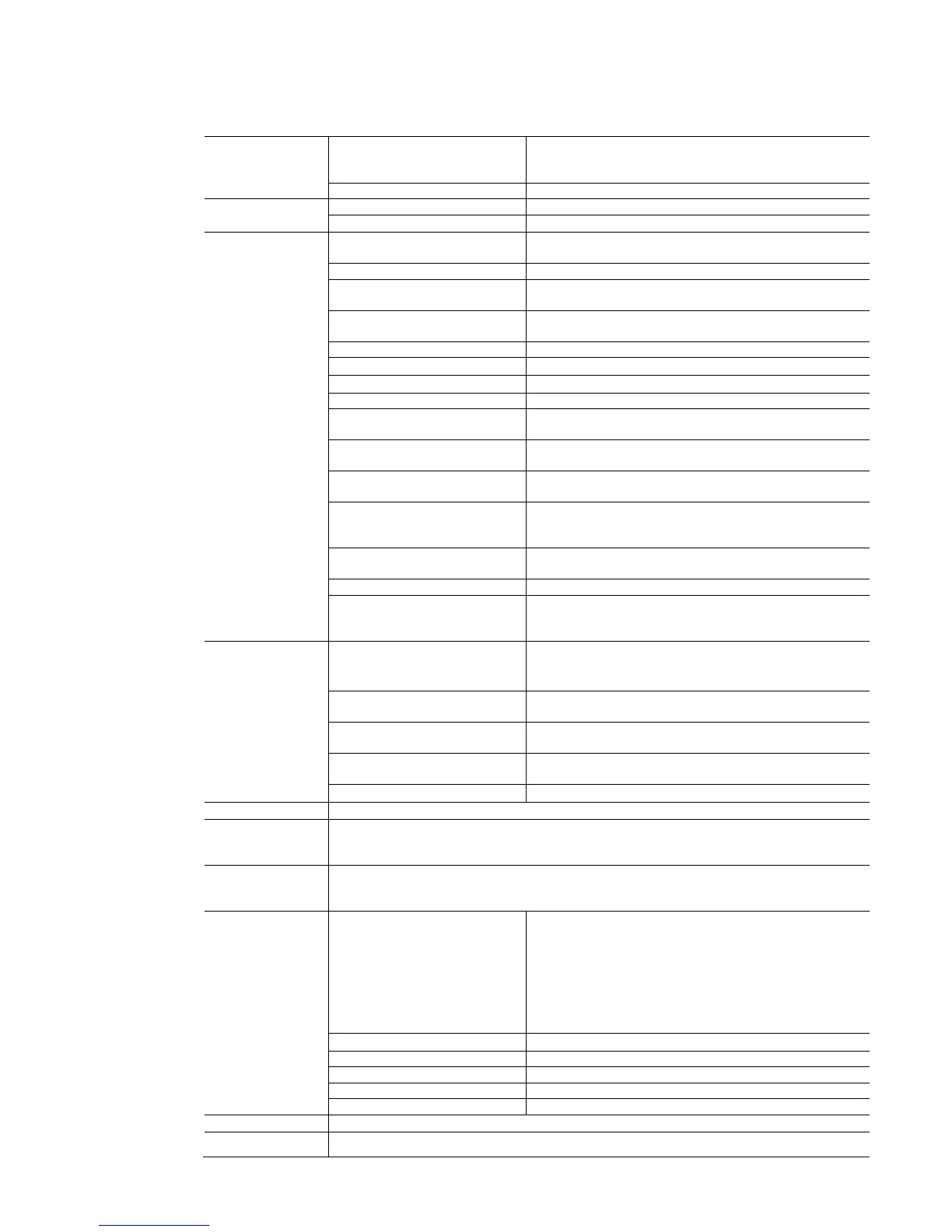

Table 2-1 Technical Specification for AC10 series IP66 Inverters

Input

Rated Voltage Range

3-phase 380-480V (+10%, -15%)

Control Mode

Carrier Frequency

2000~10000Hz; Fixed carrier-wave and random carrier-wave

can be selected by F159.

Input Frequency Resolution

Digital setting: 0.01Hz, analog setting: max frequency

SensorlessVector Control (open-loop vector control), V/F

control, PMSM sensorless vector control

5% of rated speed / 100% of rated

torque (PMSM)

150% rated current, 60 seconds.

Auto torque promotion, manual torque promotion

includes 1-20 curves.

3 kinds of modes: beeline type, square type and

under-defined V/F curve.

DC braking frequency: 0.2-50.00 Hz, braking time:

0.00~30.00s

Jogging frequency range: min frequency~ max

frequency, jogging acceleration/deceleration time:

Auto Circulating Running and

multi-stage speed running

Auto circulating running or terminals control can realize

15-stage speed running.

Easy to realize a system for process closed-loop control

Auto voltage regulation (AVR)

When source voltage changes, the modulation rate can

be adjusted automatically, so that the output voltage is

Operation

Function

Frequency Setting

Potentiometer or external analog signal (0

0~20mA); keypad (terminal)▲/▼ keys, external

control logic and automatic circulation setting.

Terminal control, keypad control or communication

control.

3 kinds of channels from keypad panel, control terminal

and MODBUS.

Frequency sources: given digit, given analog voltage,

given analog current and given MODBUS.

Auxiliary frequency Source

Built-in EMC filter, built-in braking unit, Modbus, tele-control panel

Input phase loss, Output phase loss, input under-voltage, DC over-voltage, over-current,

inverter over-load, motor over-load, current stall, over-heat, external disturbance,

under-load, pressure control, analog line disconnected.

Output frequency, rotate-speed (rpm), output current, output voltage, DC bus voltage, PID

feedback value, PID setting value, linear-velocity, types of faults, and parameters for the

system and operation; LED indicators showing the current working status of inverter.

Environment

Conditions

Equipment Location

In an indoor location with harse conditions, prevent dust

of other things from entering the inverter. Completely

protected against jets of water and heavy waves.

Meeting EN60529 standard.

For outdoor applications the drive should be installed

under a suitable cover to provide protection against

potential damage caused by direct exposure to sun, ice

Below 95% (non condensing)

Below 0.5g (acceleration)

1000m or below (3000m with derating)

Applicable Motor

0.4 ~ 15kW

TC-Hydraulik - Rsdorfer Str. 8 - 25746 Heide - Lars Lornsen - T: +49 481 909 - 34 - l.lornsen@tc-hydraulik.de - www.tc-hydraulik.de

Loading...

Loading...