10-1 Troubleshooting

AC10 Inverter

Chapter 10 Troubleshooting

When the inverter is tripped check what the cause is and rectify as required.

Take counter measures by referring to this manual in case of any malfunctions on inverter. Should it still

be unsolved, contact the manufacturer. Never attempt any repairs without due authorization.

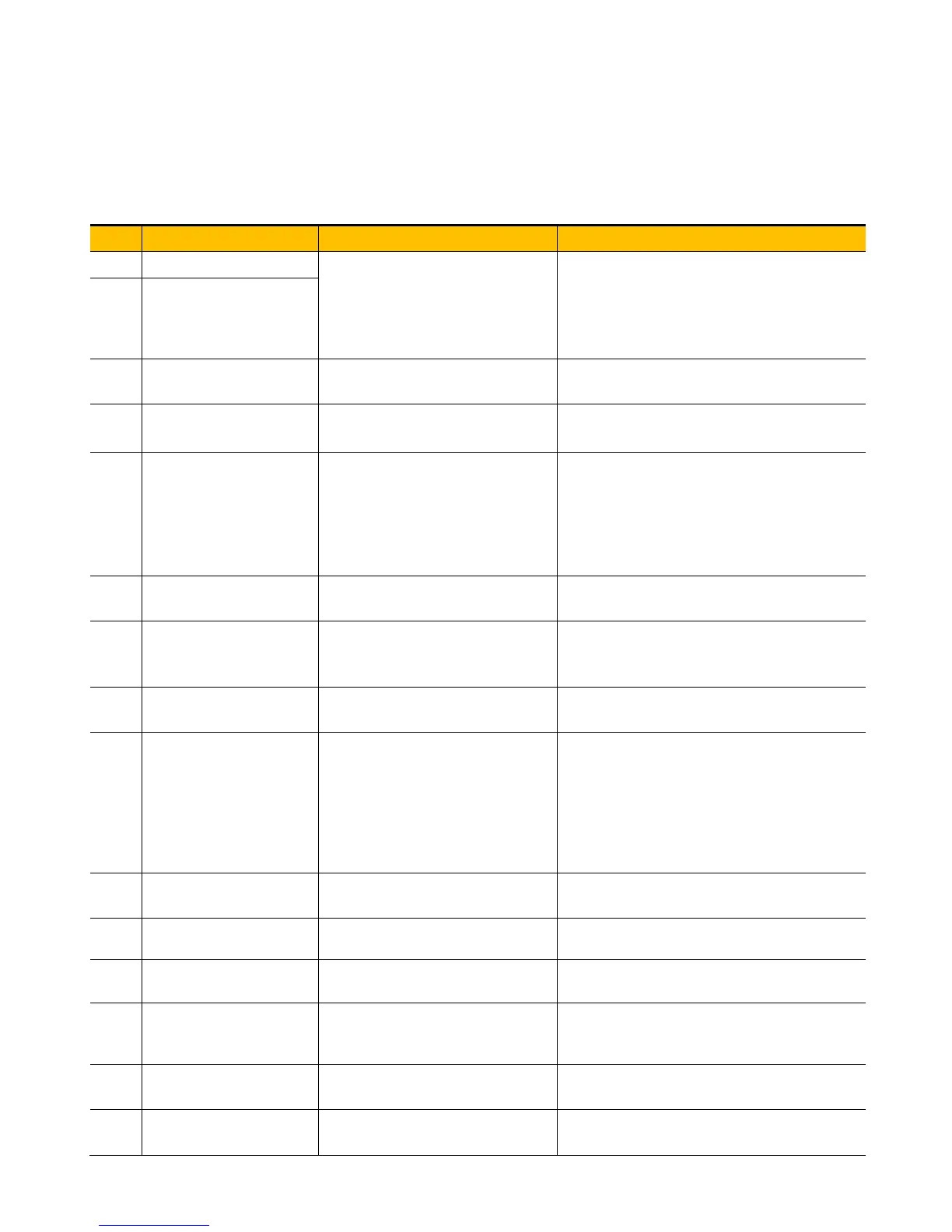

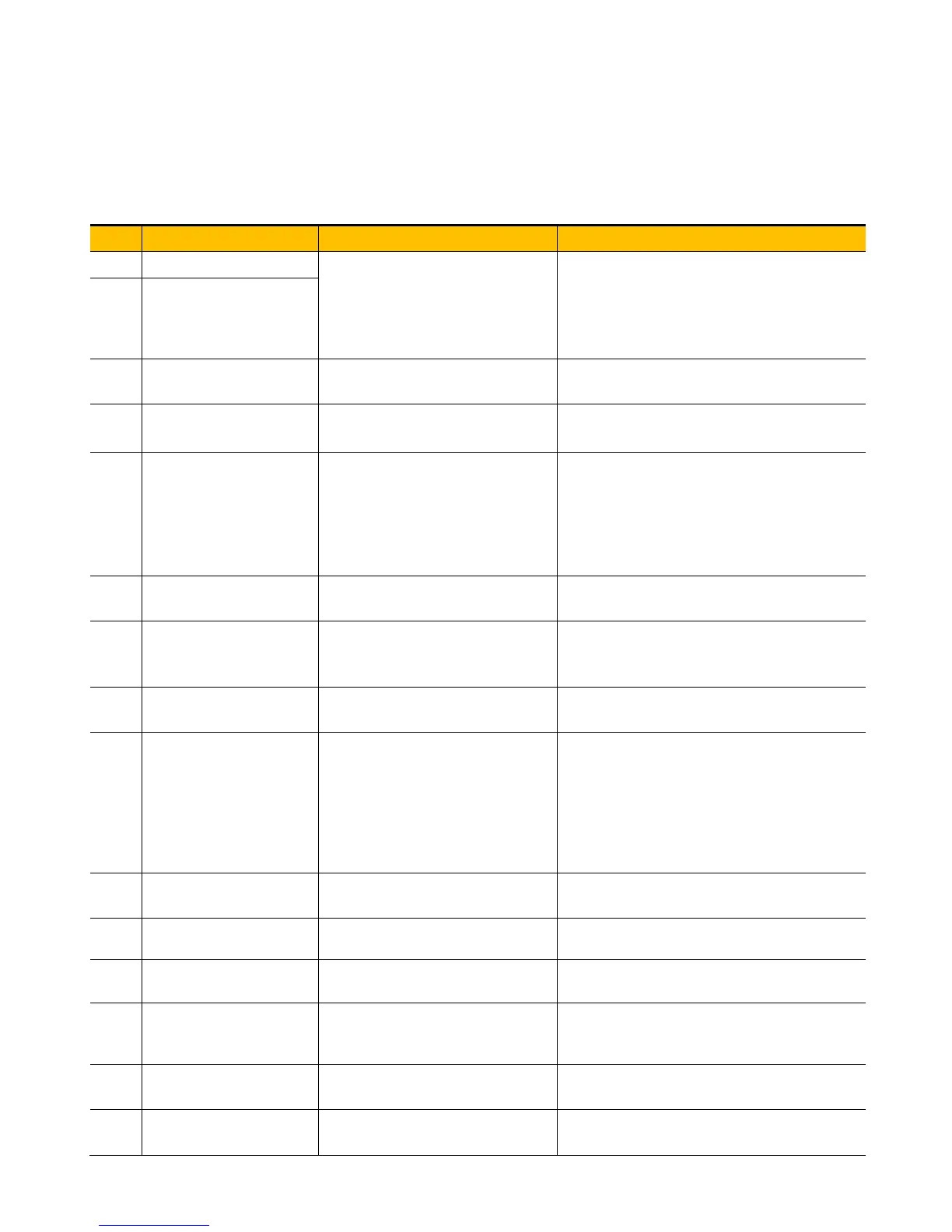

Table 10-1 Inverter’s Common Cases of Malfunctions

Fault Description Causes Possible Solution

O.C. Overcurrent

∗ too short acceleration time

∗ short circuit at output side

∗ locked rotor with motor

∗ parameter tuning is not correct

∗ prolong acceleration time

∗ is motor cable broken

∗ check if motor overloads

∗ reduce VVVF compensation value

∗ measure parameter correctly

OC1 Overcurrent 1

O.L1 Inverter Overload

∗ load too heavy

∗ reduce load; *check drive ratio

∗ increase inverter’s capacity

O.L2

Motor

Overload

∗ load too heavy

∗ reduce load; *check drive ratio

∗ increase motor’s capacity

O.E. DC Over-Voltage

∗ supply voltage too high

∗ load inertia too big

∗ deceleration time too short

∗ motor inertia rise again

∗ parameter of speed loop PID is

set abnormally

∗ check if rated voltage is input

∗ add braking resistance(optional)

∗ increase deceleration time

∗ set the parameter of rotary speed loop PID

correctly

P. F 1 . Input Phase Loss

∗ phase loss with input power

∗ check if power input is normal

∗ check if parameter setting is correct

PF0

Output

Phase Loss

∗ Motor is broken

∗ Motor wire is loose.

∗ Inverter is broken

∗ check if wire of motor is loose

∗ check if motor is broken

L.U.

Under-Voltage Protection

∗ Input voltage on the low side

∗ check if supply voltage is normal

∗ check if parameter setting is correct

O.H.

Heatsink

Overheat

∗ environment temperature too

high

∗ Heatsink too dirty

∗ poor ventilation

∗ fan damaged

∗ Carrier wave frequency or

compensation curve is too high

∗ improve ventilation

∗ clean air inlet and outlet and radiator

∗ install as required

∗ change fan

∗ Decrease carrier wave frequency or

compensation curve

AErr Line Disconnected

∗ Analog signal line disconnected

∗ Signal source is broken

∗ Change the signal line

∗ Change the signal source

Err1 Password is Wrong

∗ When password function is valid,

password is set wrong

∗ Set password correctly

Err2

Parameters Tuning

Wrong

∗ incorrect motor parameters

entered

∗ Connect motor correctly

Err3

Current Malfunction

Before Running

∗ Current alarm signal exists

before running

∗ Check if control board is properly connected

to power board

∗ Contact Parker

Err4

Current Zero Excursion

Malfunction

∗ Flat cable is loosened

∗ Current detector is broken

∗ Check the flat cable

∗ Contact Parker

Err5

PID Parameters are set

Wrong,

∗ PID parameters are set wrong.

∗

∗ Set the parameters correctly

Loading...

Loading...