73-00-00

page 30

May 01/2007

Effectivity 912/914 Series

Edition 1 / Rev. 0

d02623

BRP-Rotax

Maintenance Manual

gut

good

schlecht

bad

0,5 mm

(0,02 in)

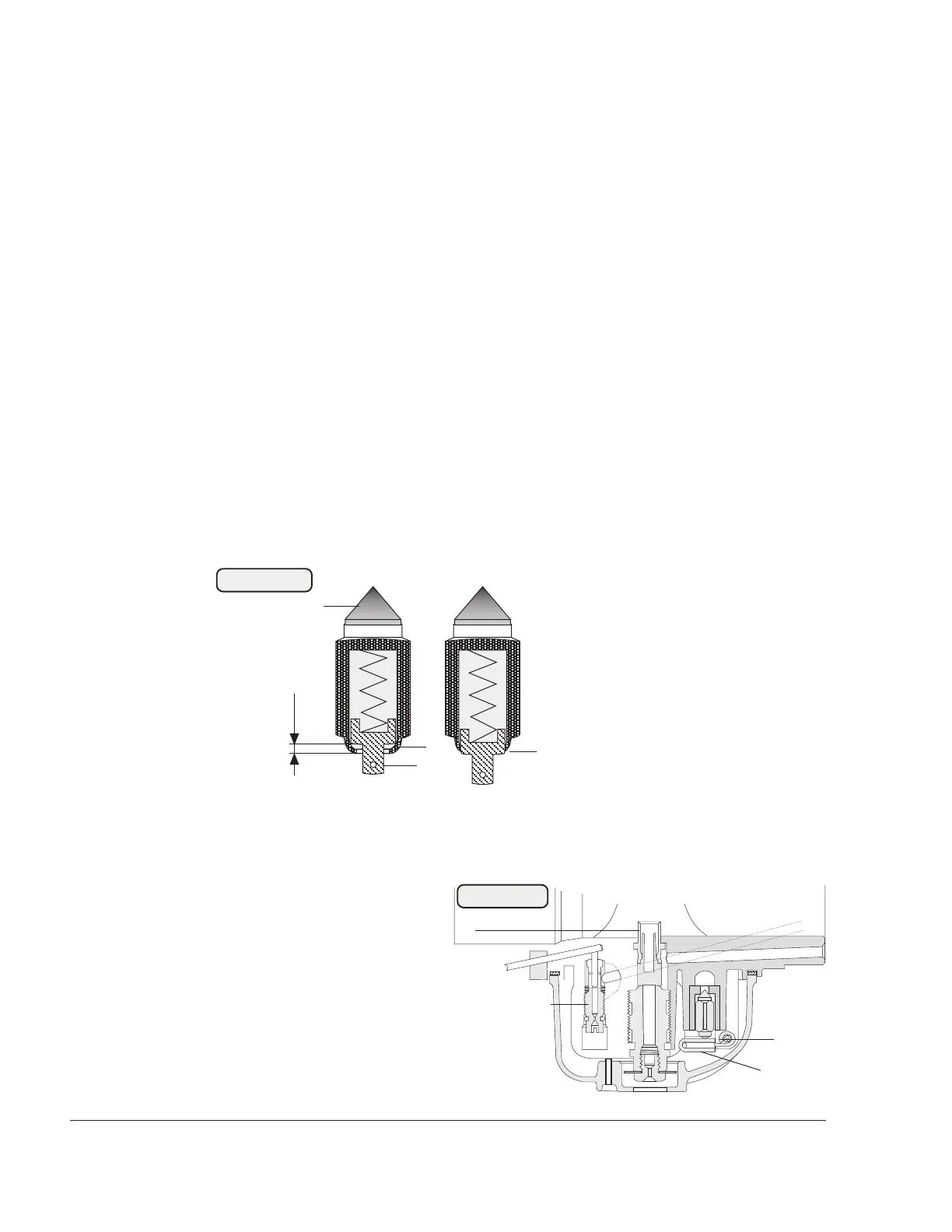

3.3.10) Float needle valve inspection

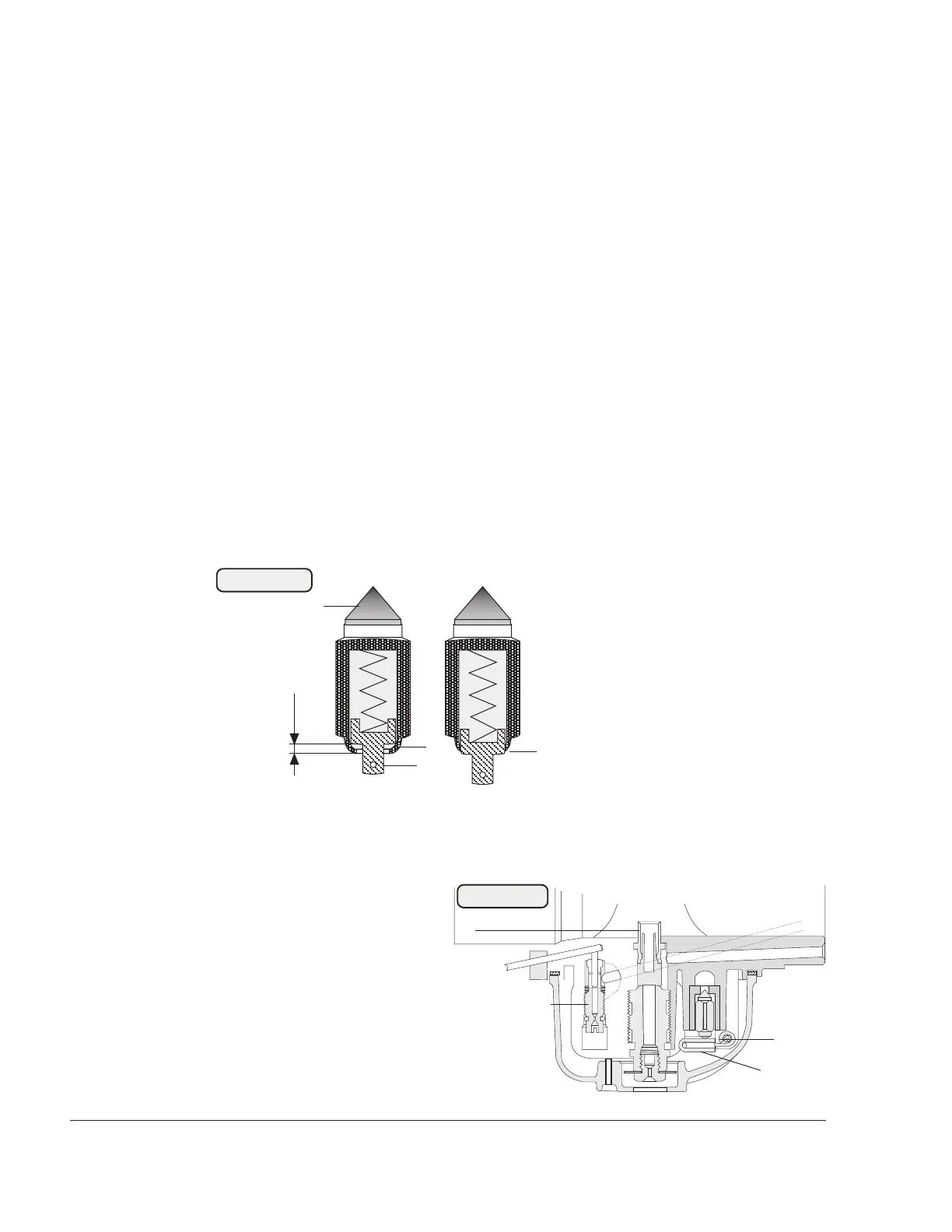

See Fig. 73-23, 73-24.

Remove the float chamber. Remove the bearing pin (4) of the float

bracket (5) and pull out the float needle.

Check fuel inlet for free passage.

Inspect the viton tip (1). Inspect clip end for visible wear to the beaded

edge (2) of the sprung pin (3), the valve must be replaced. If the

distance becomes less than 0.5 mm (.02 in.), the float level will be

affected, leading even to interruption of the fuel flow.

Insert float valve into the valve seat.

Engage float valve clip into float bracket, place it in position and fix float

bracket with pin.

Replace the float chamber and fix with spring clip.

◆ NOTE: In addition to this information, also observe the Service

Bulletins SB-912-048 and SB-914-033, ”Replacement

of pin in carburetor”, latest issue.

04928

Fig. 73-23

1

2

2

Fig. 73-24

3

00026

4

5

Loading...

Loading...