Notes

SINUMERIK 802D sl Operating and Service Training Manual Page 2

C98

C98

Section 2

Basic structure

2.1 Basic structure of NC program

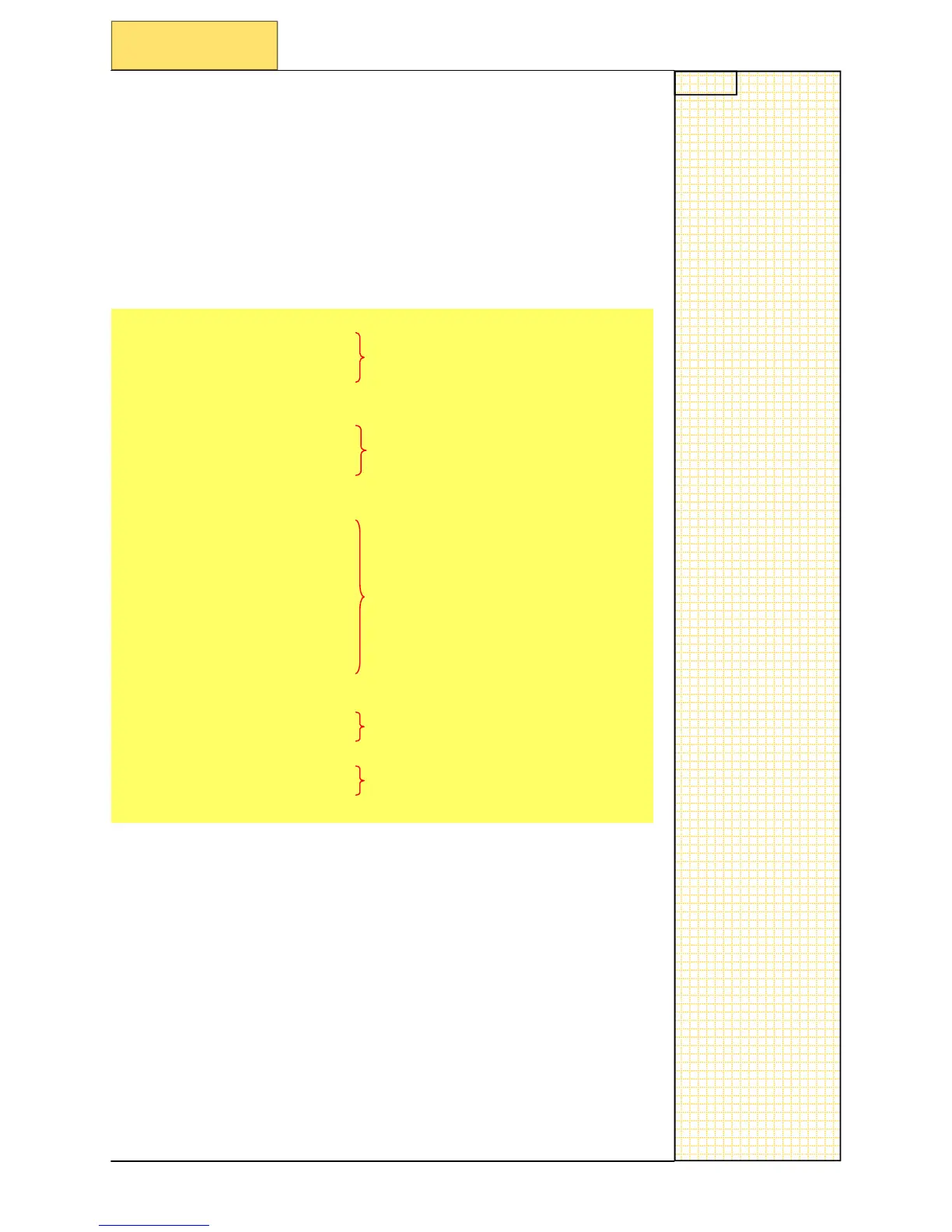

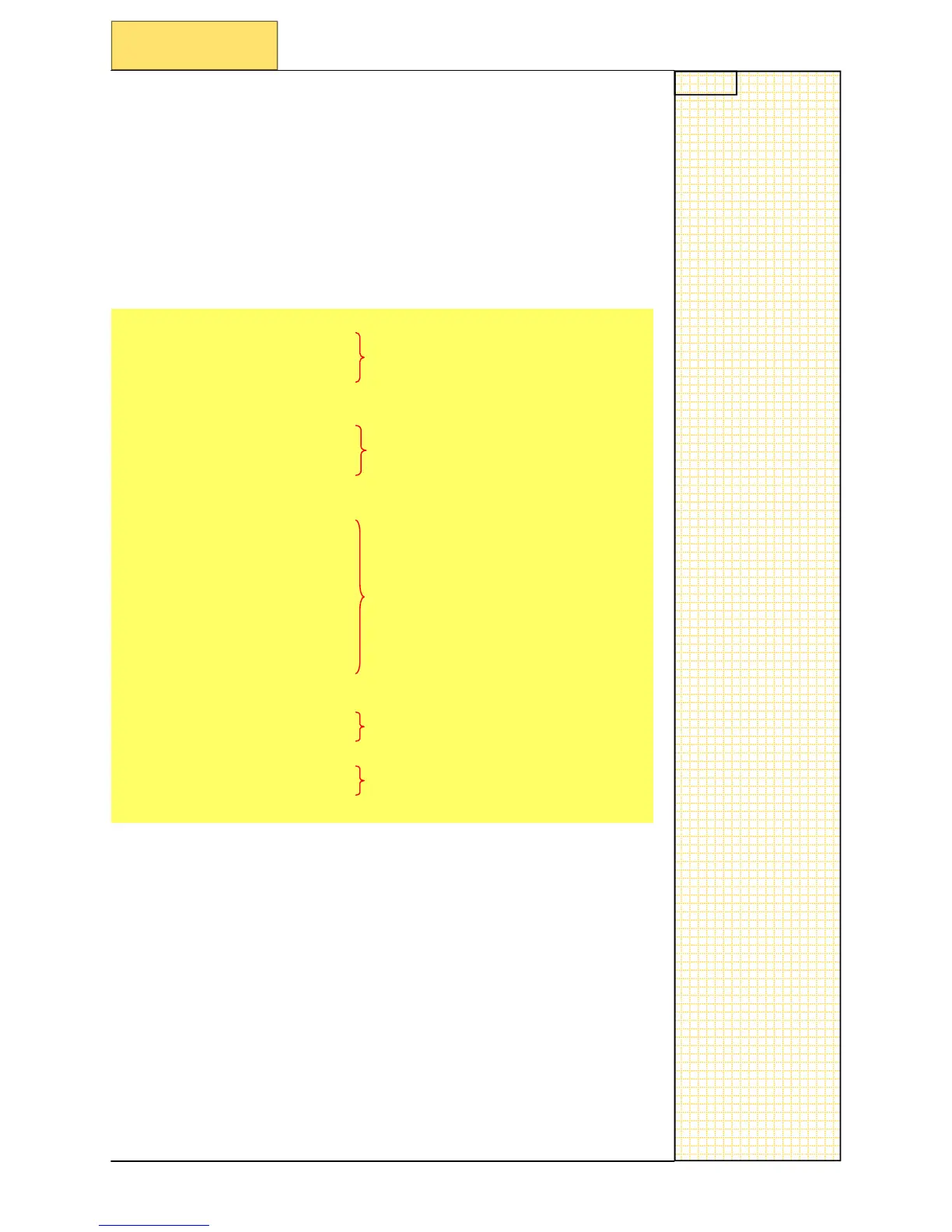

There are five basic parts to an NC program.

1.

Basic startup G functions.

2.

Call tool and set spindle speed, feed, coolant.

3.

Set geometry to cut component.

4.

Tool to safe position

5.

End of program

G00 G90 G94 G40 G17

G71

Basic G functions for pr

ogram

T1

M

6

Call tool etc

G95 S1500 F0.15 M08

G00 G54 X0

.0 Y0.0 Z50.0

….

….

….

…

.

Geometry fo

r component

….

….

….

G00 G40 Z5

0.0

X0.0 Y200.0 Z200.0

Safe positio

n for tool change

M30

End of program

You will note that for each tool there is always :

• Call tool etc

• Geometry for component

• Safe position for tool change

This will be t

he same for ever tool that is written in the NC program

If you keep to a good ba

sic structure, this will make the program safer to

run and easier to perform a block search.

Loading...

Loading...