Loading...

Loading...

Do you have a question about the Suzuki VL1500K5 and is the answer not in the manual?

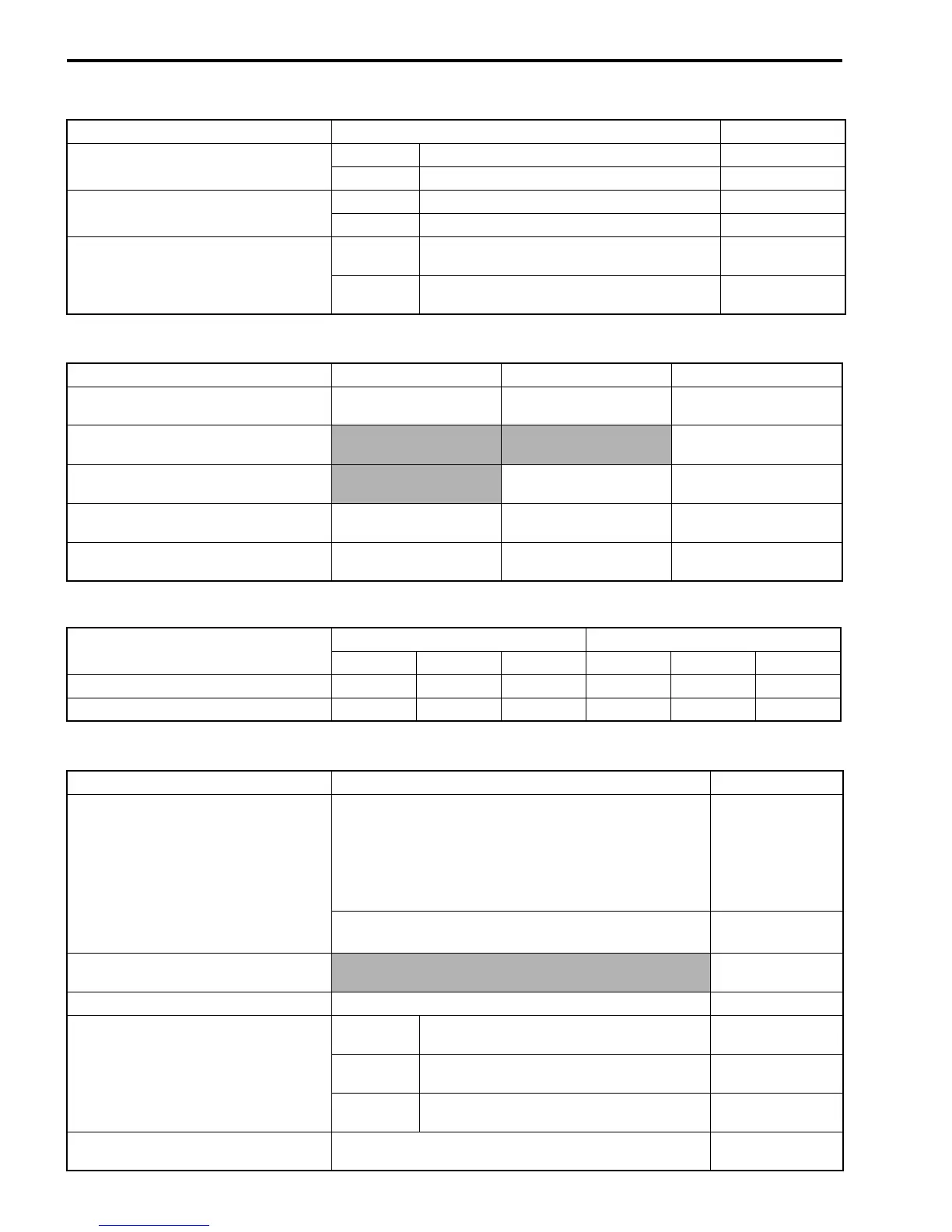

| Model | VL1500K5 |

|---|---|

| Year | 2005 |

| Category | Cruiser |

| Displacement | 1462 cc |

| Compression Ratio | 9.5:1 |

| Fuel System | Fuel injection |

| Lubrication | Wet sump |

| Starter | Electric |

| Transmission | 5-speed |

| Final Drive | Shaft |

| Rear Brakes | Single hydraulic disc |

| Engine Type | V-twin |

| Ignition | Digital electronic |

| Front Suspension | Telescopic |

| Rear Suspension | Swingarm |

| Front Brakes | Dual hydraulic discs |

| Front Tire Size | 150/80-16 |

| Overall Height | 1145 mm (45.1 inches) |

| Seat Height | 700 mm (27.6 inches) |

| Fuel Capacity | 18.0 L (4.8 US gal) |

| Bore x Stroke | 96.0mm x 101.0mm |

| Rear Tire Size | 180/70-15 |

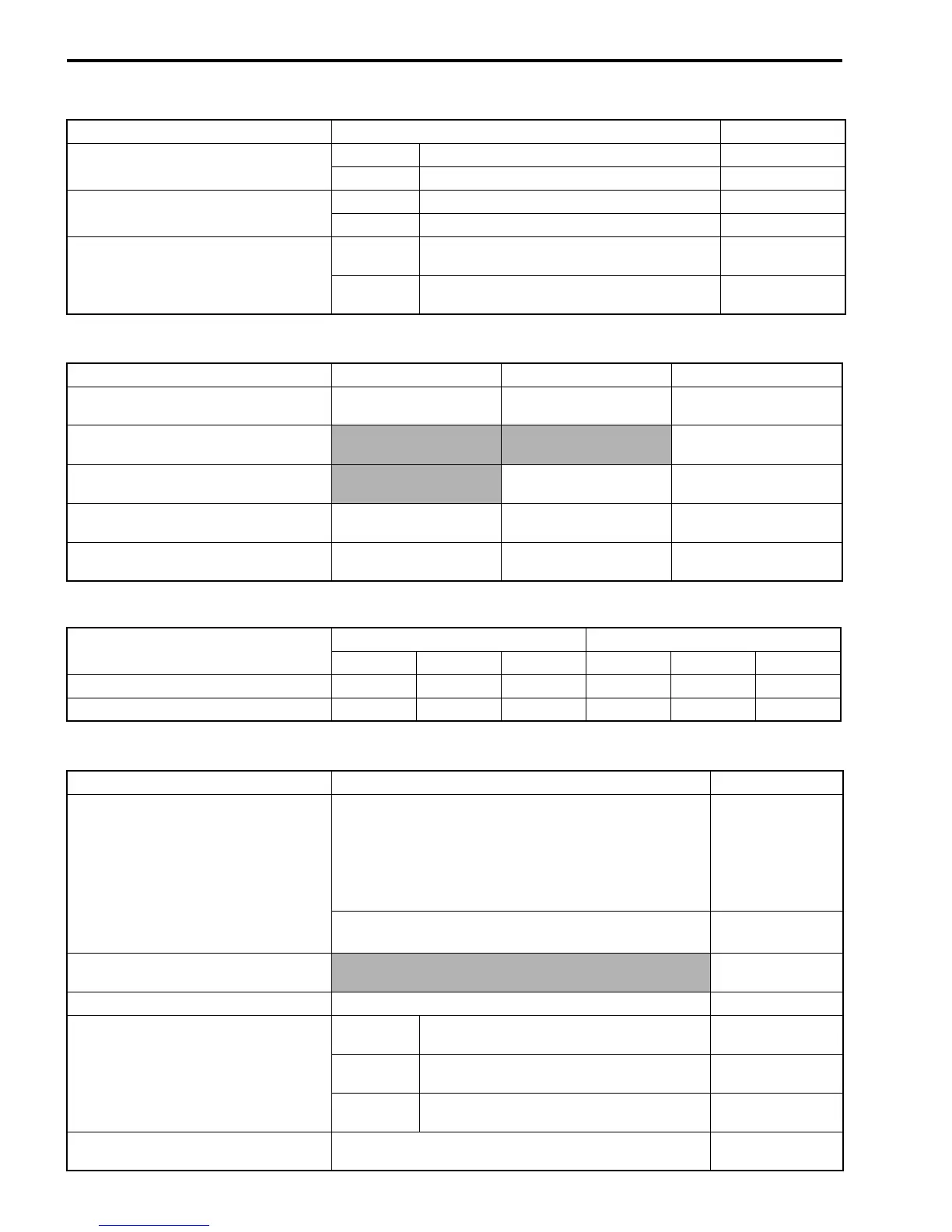

Detailed dimensions and dry mass of the motorcycle.

Technical specifications for the engine.

Specifications for the drive train components.

Specifications for chassis, suspension, brakes, and wheels.

Specifications for the electrical system components.

Capacities for fuel tank, engine oil, and final gear oil.

Procedure for inspecting and replacing the fuel hose.

Procedure for checking and adjusting engine idle speed.

Procedure for adjusting throttle cable play.

Periodic inspection and adjustment of throttle valve synchronization.

Periodic inspection of the PAIR (air supply) system.

Tightening procedures for exhaust and chassis bolts and nuts.

Components on the engine's left side removable with engine in place.

Components on the engine's right side removable with engine in place.

Components in the engine's center removable with engine in place.

Step-by-step procedure for removing the engine from the frame.

Step-by-step procedure for installing the engine into the frame.

Procedures for removing and reassembling the gear position switch.

Procedures for removing and reassembling the EOT sensor.

Inspection and servicing procedures for the camshaft.

Checking for wear on the camshaft.

Precautions for handling electrical connectors and couplers safely.

Precautions to follow when dealing with fuses.

Precautions for handling the ECM and various sensors.

Procedure for inspecting electrical circuits for open circuits.

Methods for performing continuity and voltage checks.

Procedure for inspecting electrical circuits for short circuits to ground.

Guidelines and precautions for using the multi-circuit tester.

Factors that determine fuel injection time.

Signals used for compensating fuel injection time.

Signals that control fuel injection stop.

Self-diagnosis function modes and indicators for the user.

Self-diagnosis function mode for dealers.

Form for analyzing customer complaints to diagnose issues.

List of common motorcycle problems and symptoms.

Factors influencing problem occurrence.

Preliminary visual checks before electronic diagnosis.

Steps for performing self-diagnosis.

Procedures for using the SDS diagnostic tool.

Steps to reset SDS diagnosis data.

Displaying and interpreting data during DTC detection.

List of malfunction codes and their corresponding defective conditions.

Procedure for removing the fuel tank.

Procedure for inspecting fuel pressure.

Inspecting fuel pump operation and discharge amount.

Procedure for inspecting the fuel pump relay.

Procedures for removing and disassembling the fuel pump assembly.

Diagram illustrating the components of the throttle body.

Procedure for removing the air cleaner box.

Procedures for removing and disassembling the throttle body.

Procedures for reassembling and installing the throttle body.

Procedure for synchronizing throttle valves using a vacuum tester.

Procedure for setting the throttle position sensor.

Inspect and service the IAP sensor.

Inspect and service the TP sensor.

Inspect and service the STP sensor.

Inspect and service the CKP sensor.

Inspect and service the IAT sensor.

Inspect and service the EOT sensor.

Inspection and service procedures for the tip-over sensor.

Inspection procedures for the HO2 sensor on specified models.

Procedures for removing and installing the motorcycle seats.

Diagram illustrating the components of the front fork.

Procedures for removing and disassembling the front fork.

Inspection of fork spring, oil, and reassembly procedures.

Measuring generator coil resistance and no-load performance.

Measuring voltages at the regulator/rectifier terminals.

Inspecting the side-stand and ignition interlock system components.

Inspection procedures for the gear position switch.

Troubleshooting steps for ignition system faults like no spark.

Overview of speedometer, LEDs, and indicators.

Procedures for servicing the speedometer unit and its components.

Information regarding the fuel pump relay.

Inspecting continuity of various switches.

Guide for routing wiring harnesses on the motorcycle.

Guide for routing cables and hoses on the motorcycle.

Specific routing for the front brake hose.

Specific routing for the rear brake hose.

Routing for fuel system hoses.

Routing for PAIR system hoses.

Installation of meter and fuel inlet covers.

Installation of frame upper covers.

Installation of frame head covers.

Identification of points requiring grease.

Procedure for installing the brake pedal.

Tightening torques for FI and intake air system components.

Tightening torques for chassis components.

Standard and limit values for valve and guide dimensions.

Service data for camshafts and cylinder heads.

Service data for cylinder, piston, and rings.

Service data for conrod and crankshaft components.

Service data for oil pump, clutch, and drive train.

Specifications for FI system sensors, injectors, and pumps.

Specifications for throttle body and electrical components.

Specifications for lighting and brake system components.

Specifications for wheels, suspension, tire pressure, and fluids.

Description of the fuel injection system for emission control.

Description of the crankcase emission control system.

Description of the PAIR system for exhaust emission control.

Inspecting PAIR system hoses, pipes, reed valve, and solenoid valve.

Diagram illustrating the PAIR system.

Routing of PAIR system hoses.