7. CYLINDER/PISTON SYM

7-2

PRECAUTIONS IN OPERATION

General Information

Ÿ Both cylinder and piston service cannot be carried out when engine mounted on frame.

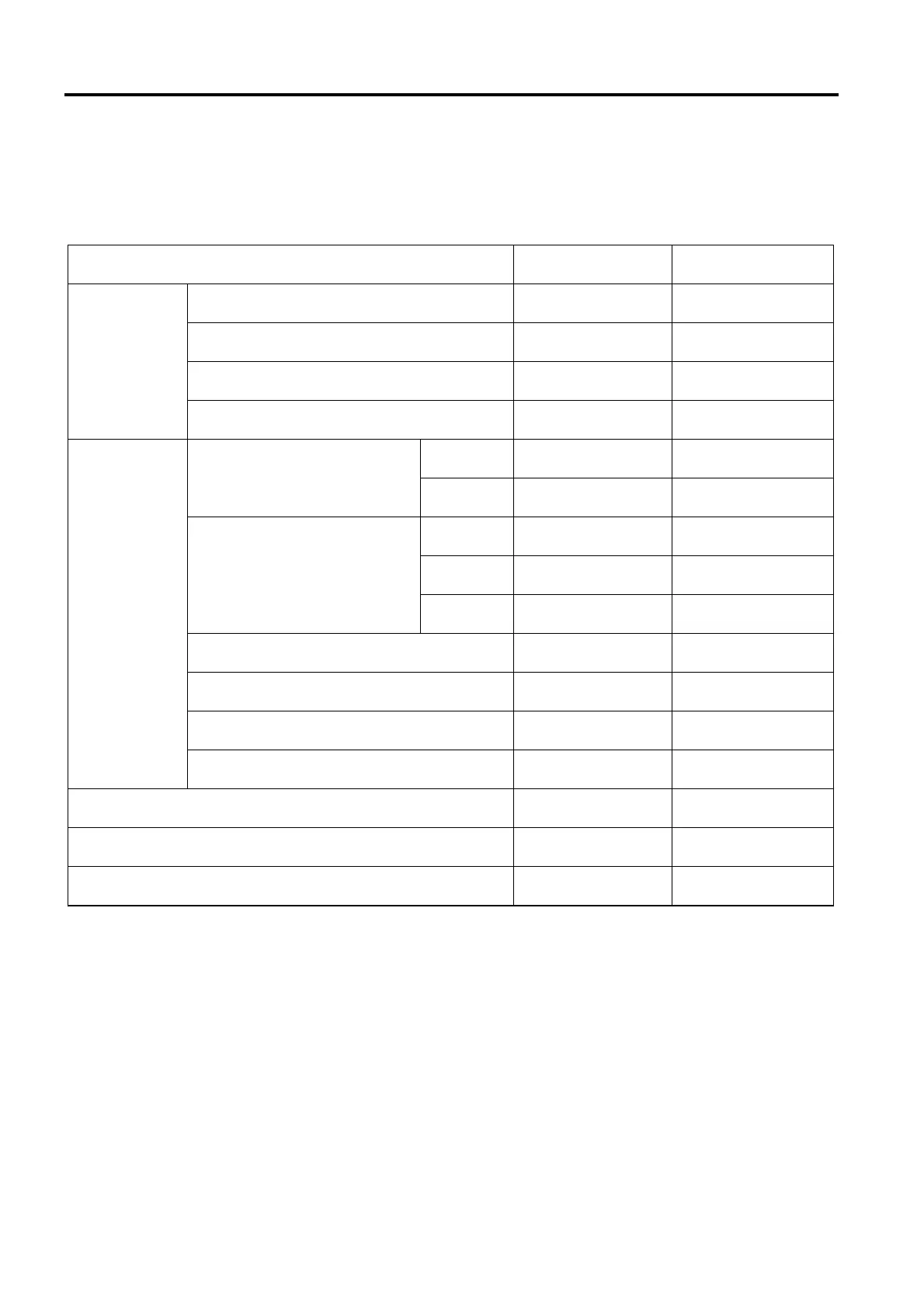

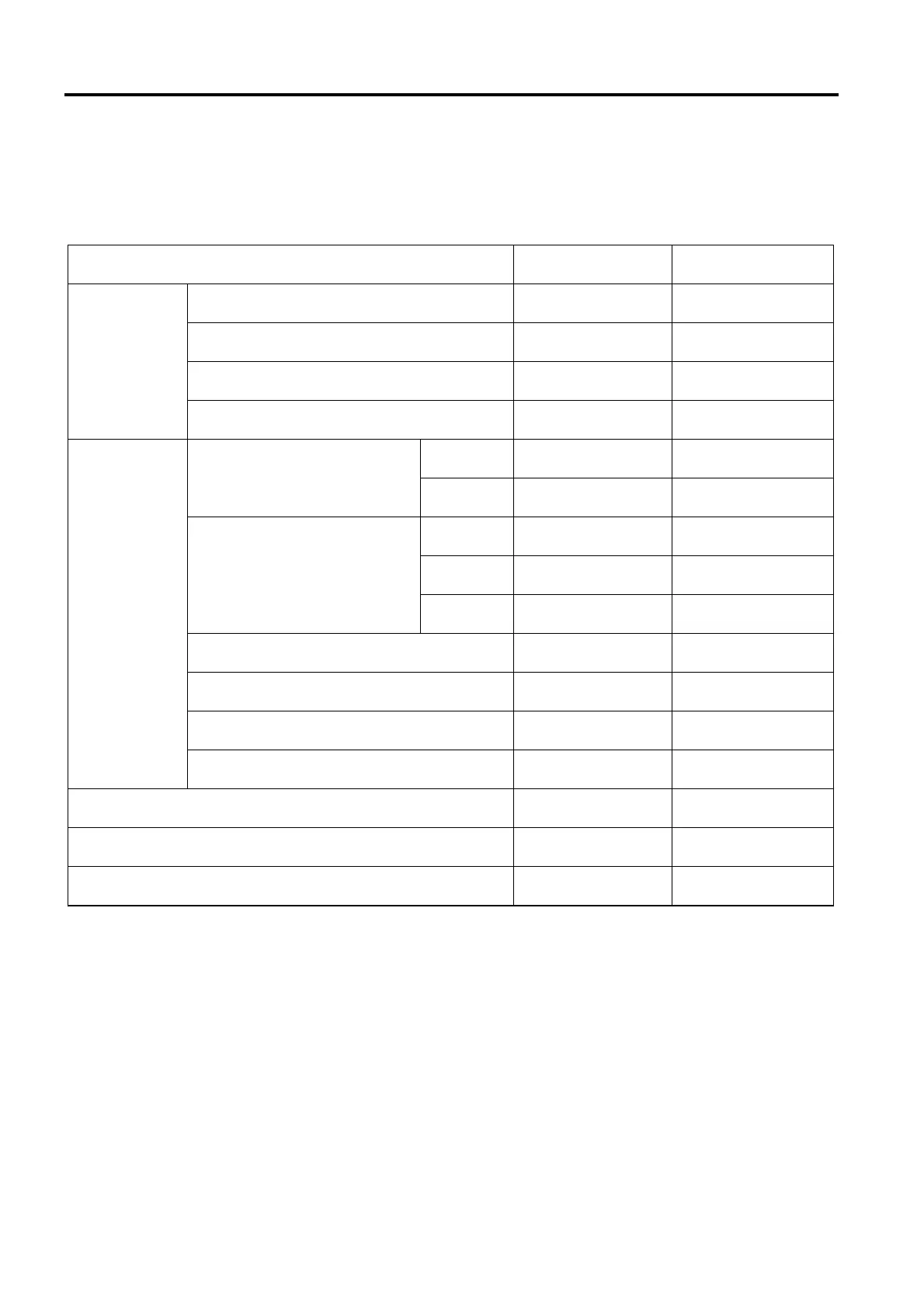

Specification unit: mm

Item Standard Limit

ID 52.395~52.415 52.50

Bend/wrap age Less than 0.05 0.050

Roundness Less than 0.01 0.050

Cylinder

Cylindrical Less than 0.05 0.050

Top ring 0.05~0.105 0.145

Clearance between

piston and rings

2

nd

ring 0.05~0.105 0.145

Top ring 0.100~0.2500 0.500

2

nd

ring 0.300~0.500 0.750

Ring-end gap

Oil ring

0.200~0.700

-

OD of piston 52.385~52.405 52.310

Piston OD measurement position

Lower-end up 7mm

of piston skirt

-

Clearance between piston and

cylinder

0.005~0.015 0.100

Piston/

Piston ring

ID of piston pin hole 15.002~15.008 15.040

OD of piston pin 14.994~15.00 14.96

Clearance between piston and piston pin 0.002~0.014 0.020

ID of connecting rod small-end 15 15.06

TROUBLE DIAGNOSIS

Low Or Unstable Compression Pressure

l Cylinder or piston ring worn out.

l Compress pressure to high.

l Too much carbon deposited in

combustion chamber and piston.

Knock or Noise

l Cylinder or piston ring worn out.

l Carbon deposits on cylinder head

top-side.

l Piston pin hole and piston pin wear out.

Smoking in Exhaust Pipe

l Piston or piston ring worn out.

l Piston ring installation improperly.

l Cylinder or piston damage.5

Engine Overheat

l Carbon deposits on cylinder head top

side.

Loading...

Loading...