11. CRANKCASE/CRANKSHAFT SYM

OPERATIONAL PRECAUTIONS

General Information

l This Section contains descriptions concerning disassembly of the crankcase so that the

crankshaft can be serviced.

l Complete following operations before disassembling crankcase.

Engine Chapter 5

Cylinder head Chapter 6

Cylinder and piston Chapter 7

V-belt Drive pulley Chapter 8

AC generator/ Starting Clutch Chapter 10

Start motor Chapter 16

l If the crankshaft bearing or timing sprocket need be replaced, then the crankshaft set

have to replaced.

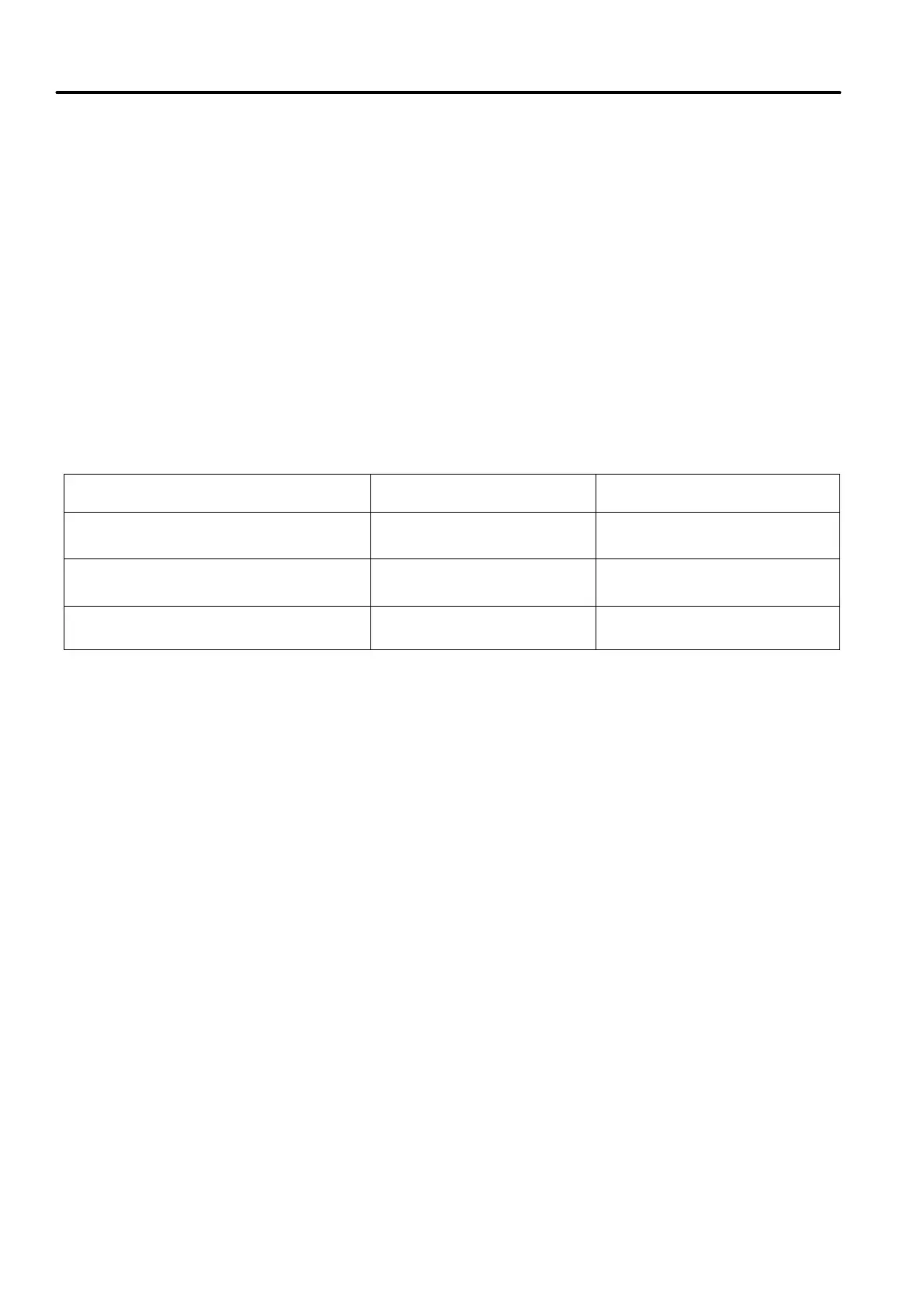

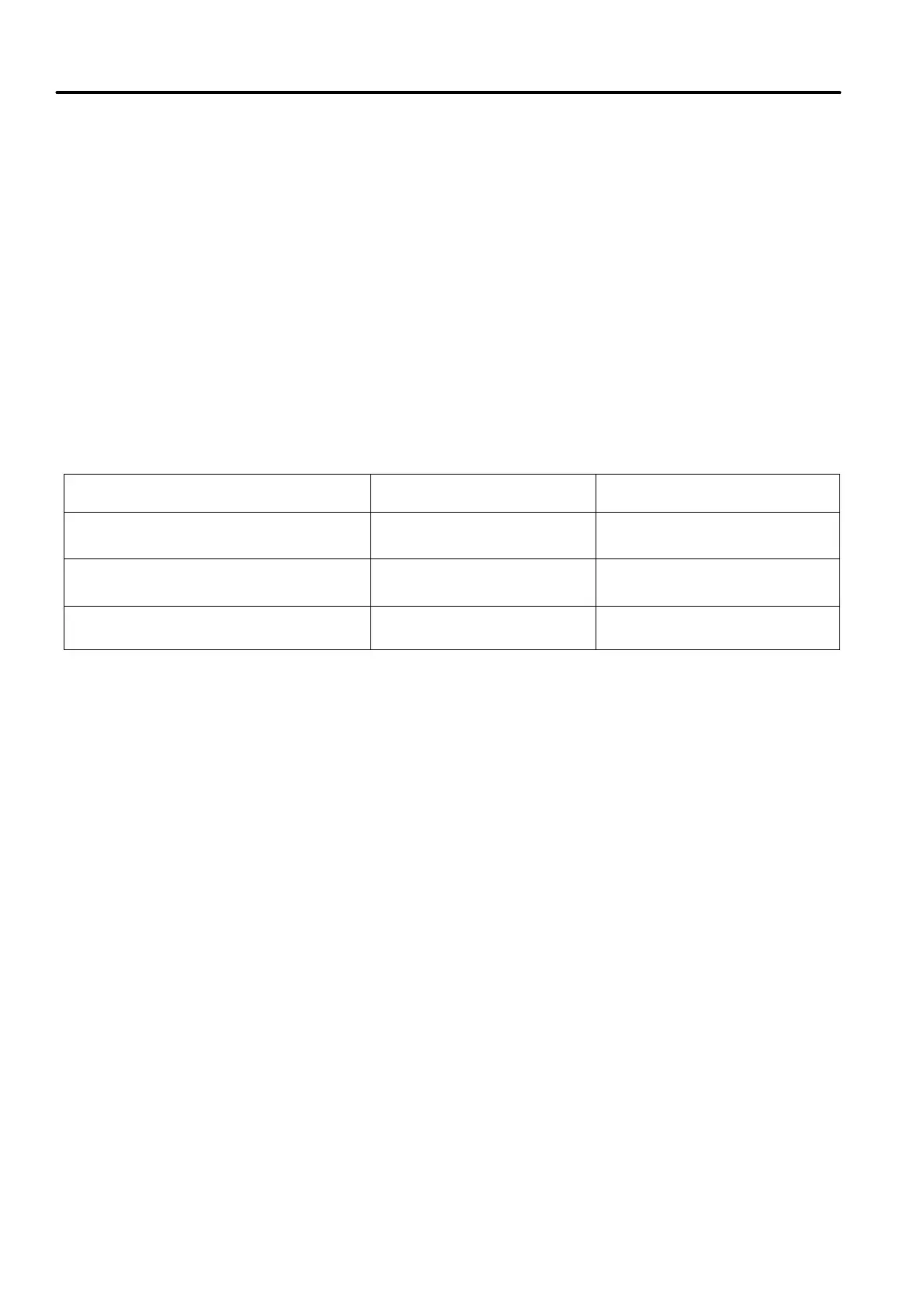

Specification Unit: mm

Item Standard Limit

Left, right clearance of the big end

of the connecting rod

0.100~0.350 0.550

Radial clearance of the big end of

the connecting rod

0.000~0.008 0.050

Run-out

Left side: Below 0.035

Right side: Below 0.035

Left side: 0.035

Right side: 0.030

Torque value

Bolts for crankcase 1.5~2.0 kgf-m

Bolts for cylinder/cylinder head 0.7~1.0 kgf-m

Engine oil draining plug 3.5~4.5 kgf-m

Bolts for cam chain tensioner 0.8~1.2 kgf-m

Special Service Tools

Crankcase remover/set

Crankshaft installation puller

Inner type bearing puller

Outer type bearing puller

Bearing pressing tools

Oil seal pressing tools

TROUBLE DIAGNOSIS

Engine noise

• Loose crankshaft bearing

• Loose crankshaft pin bearing

• Wear piston pin or piston pin hole

Loading...

Loading...