12. Crankshaft / Crankcase

12-2

General Information

Operational precautions

• This Section concerns disassembly of the crankcase for repair purpose.

• Remove following components before disassembling crankcase.

─Engine Section 5

-Cylinder head Section 6

-Cylinder and piston Section 7

-Drive pulley and driven pulley Section 8

-AC generator/Start driven gear Section 10

-Starting motor Section 16

• In case it requires replacing the crankshaft bearing, the driving chain of engine oil pump or the

timing chain, it is preferably to replace crankshaft as a unit.

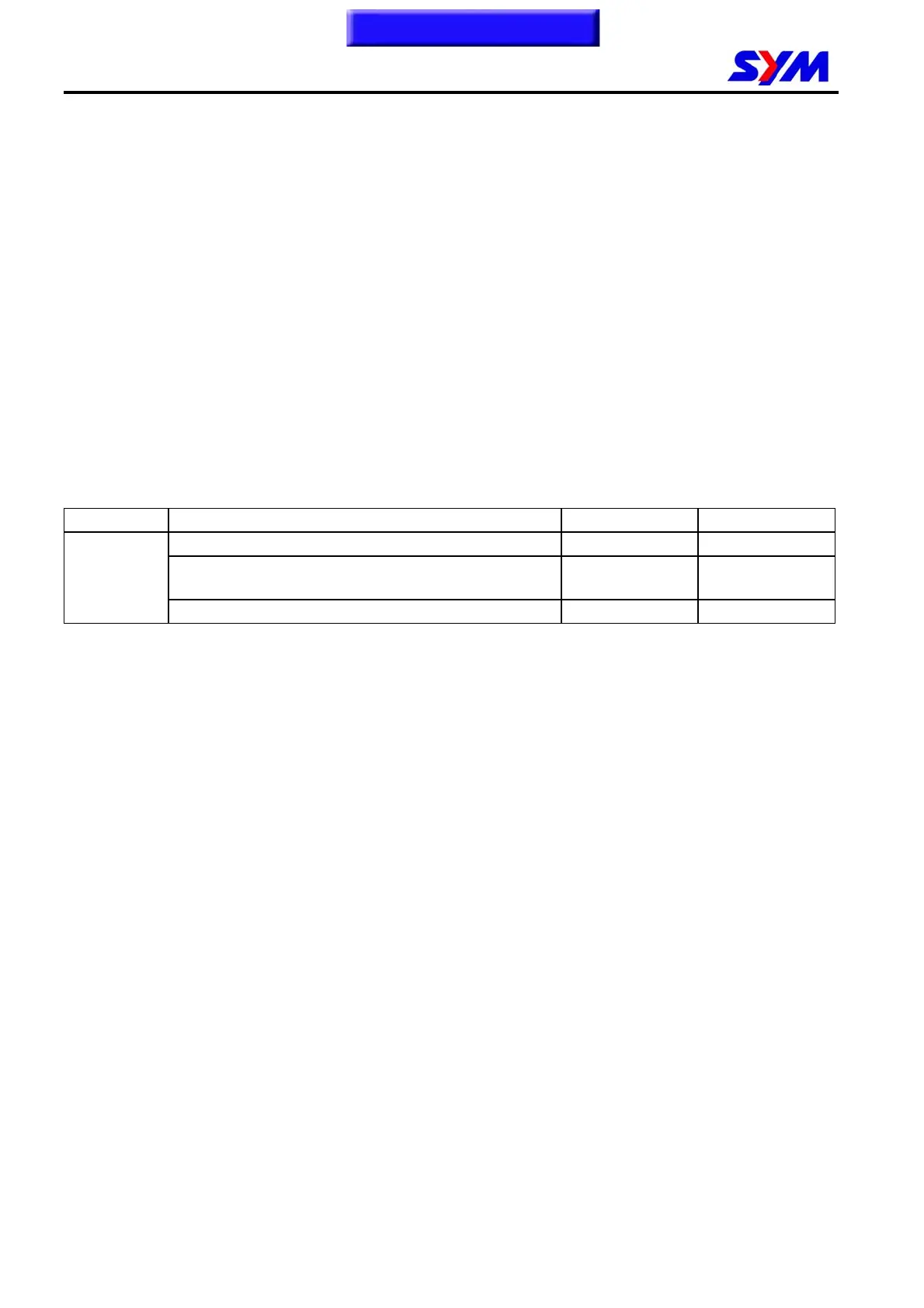

Service data

Unit: mm

Item Standard Limit

Connecting rod side clearance of the big end 0.100~0.400 0.600

Vertical clearance of the big end of the connecting

rod

0~0.008 0.050

Crankshaft

Run-out - 0.100

Torque value

Bolts for crankcase 0.8~1.2kgf-m

Bolts for cam chain adjuster 1.2~1.6kgf-m

Tools

Special tools

R/L. crank disassemble/ install tool

L. crank shaft bearing driver

Crank shaft bearing fixing socket

Crank shaft puller

Outer bearing puller

Inner bearing puller

Troubleshooting

Engine noise

• Loose crankshaft bearing

• Loose crankshaft pin bearing

• Worn out piston pin and pin hole

To this chapter contents

Loading...

Loading...