EM-97ENGINE MECHANICAL Cylinder Block

INSPECTION AND REPAIR OF PISTON AND

CONNECTING ROD ASSEMBLIES

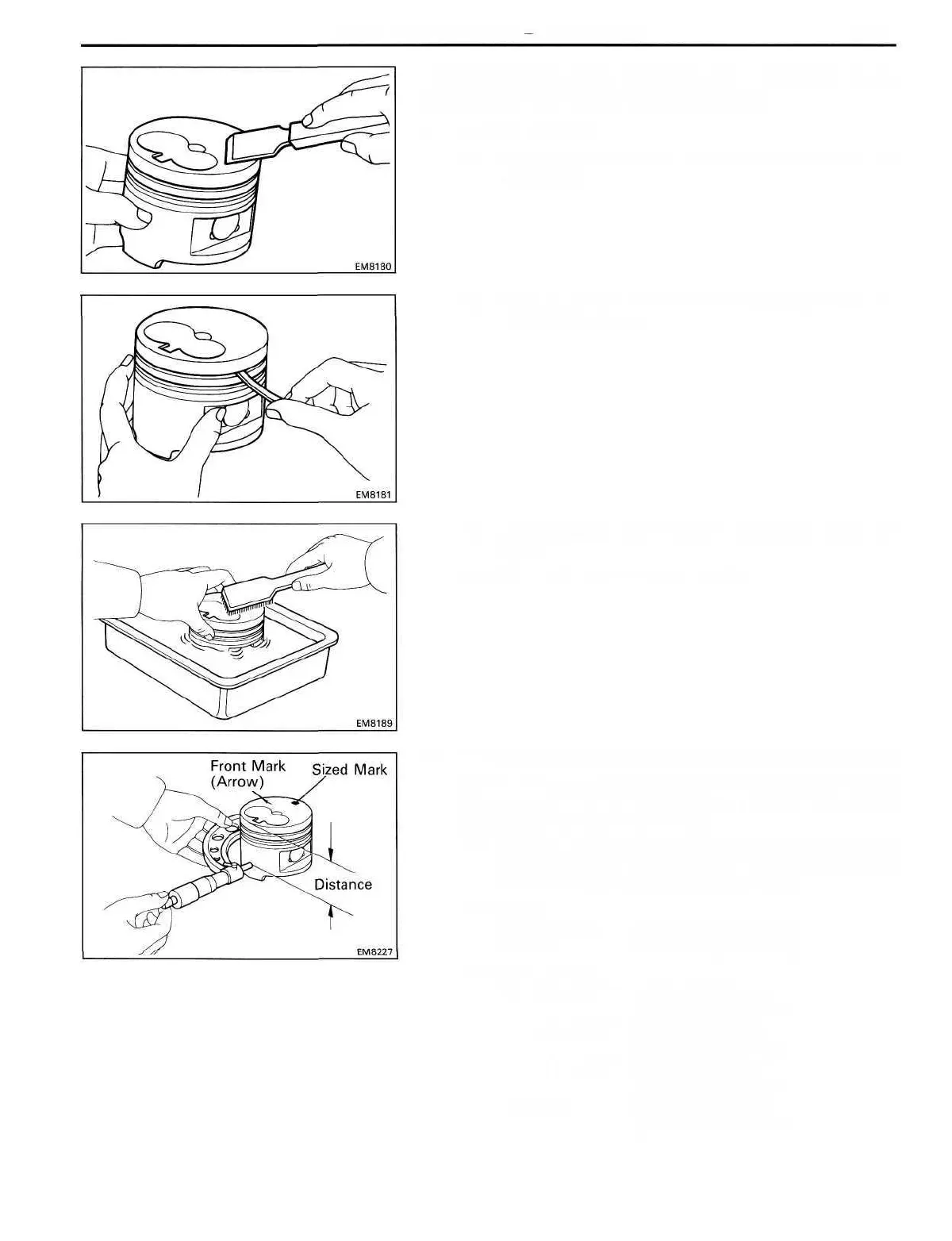

1. CLEAN PISTON

(a) Using a gasket scraper, remove the carbon from the

piston top.

(b) Using a groove cleaning or broken ring, clean the

piston ring grooves.

(c) Using solvent and a brush, thoroughly clean the

piston.

NOTICE: Do not use a wire brush.

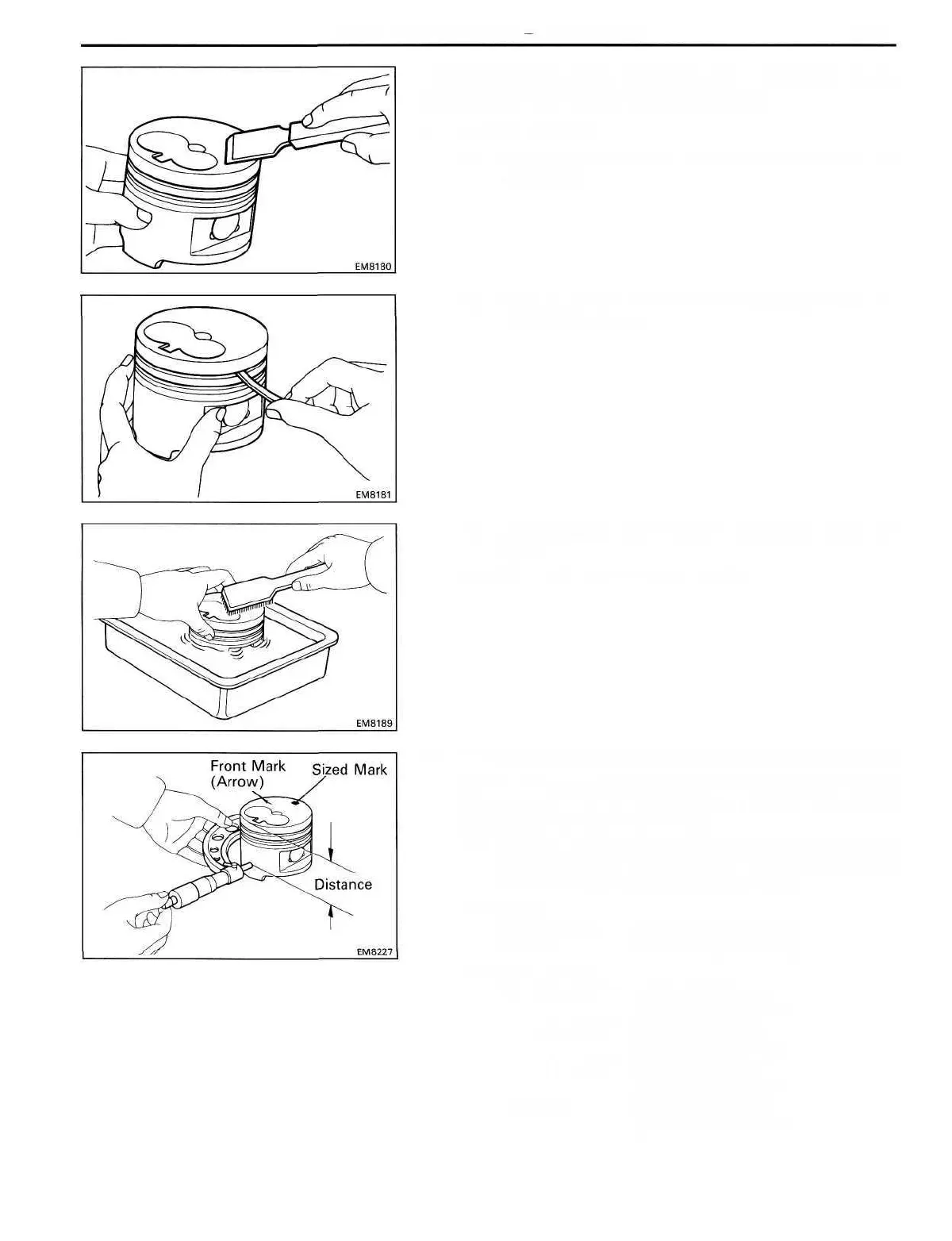

2. INSPECT PISTON DIAMETER AND OIL CLEARANCE

HINT: There are three sizes of the standard piston diam-

eter, marked "1", "2" and "3" accordingly. The mark is

stamped on the top of the piston.

(a) Using a micrometer, measure the piston diameter at

right angles to the piston pin center line, at the

indicated distance from the piston head.

Distance:

1PZ and 1 HZ 58.6 mm (2.3071 in.)

1HD-T 65.7 mm (2.5866 in.)

Piston diameter:

STD Mark "1" 93.95-93.96 mm

(3.6988-3.6992 in.)

Mark "2" 93.96 - 93.97 mm

(3.6992-3.7000 in.)

Mark "3" 93.97-93.98 mm

(3.7000-3.7000 in.)

O/S 0.50 94.45 - 94.48 mm

(3.7185-3.7197 in.)

Loading...

Loading...