EM-99

ENGINE MECHANICAL - Cylinder Block

(c) Using a thickness gauge, measure the end gap.

Standard end gap:

No.1 0.27-0.54 mm

(0.0106-0.0213 in.)

No.2 0.40-0.62 mm

(0.0157-0.0244 in.)

Oil 0.20-0.52 mm

(0.0079-0.0205 in.)

Maximum end gap:

No.1 1.34 mm (0.0591 in.)

No.2 1.42 mm (0.0551 in.)

Oil 1.32 mm (0.0520 in.)

If the end gap is greater than maximum, replace the piston

ring. If the end gap is greater than maximum, even with a

new piston ring, rebore all five (1 PZ) or six (1 HZ and

1 HD-T) cylinders or replace the cylinder block.

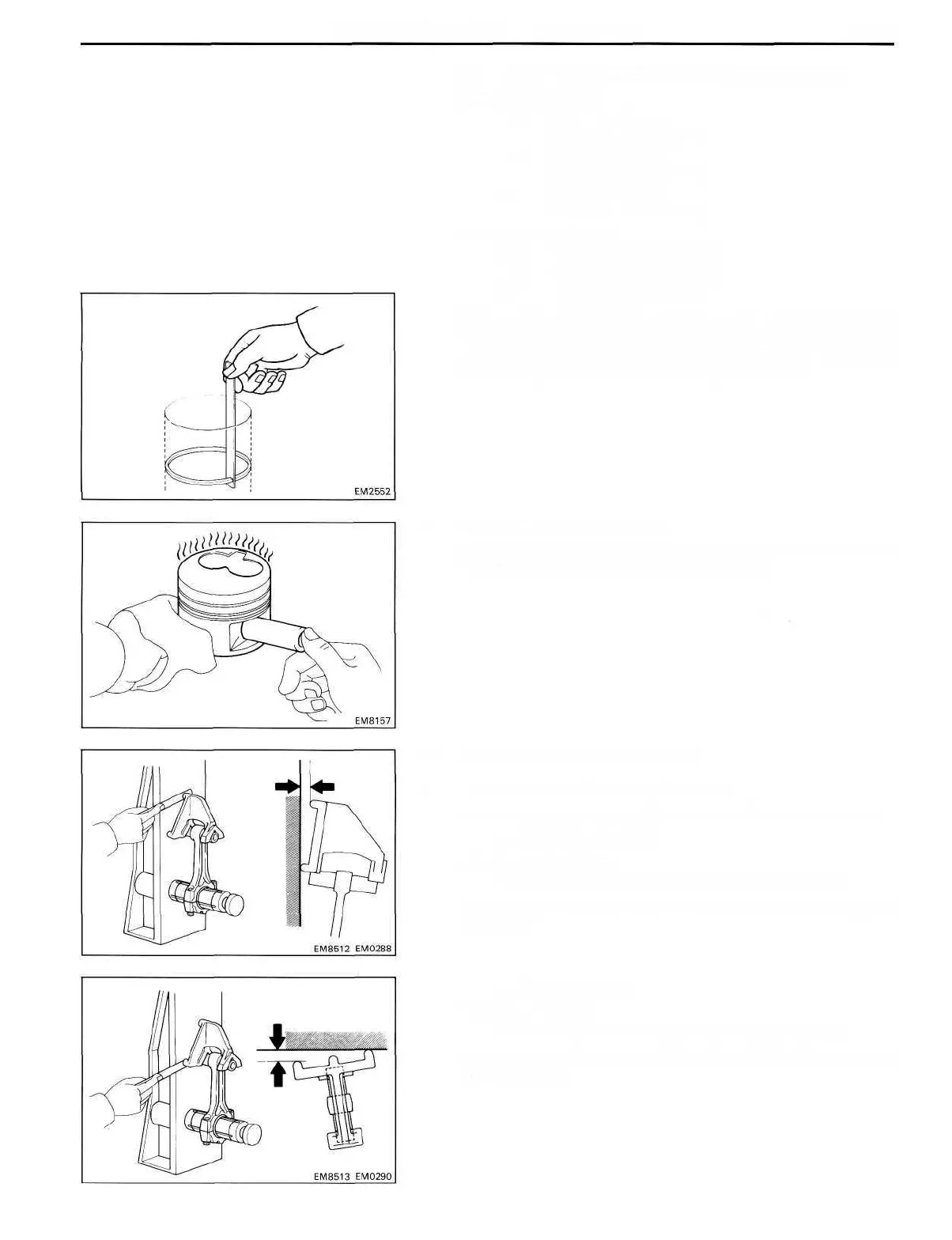

5. INSPECT PISTON PIN FIT

At 80°C (176°F), you should be able to push the piston pin

into the piston pin hole with your thumb.

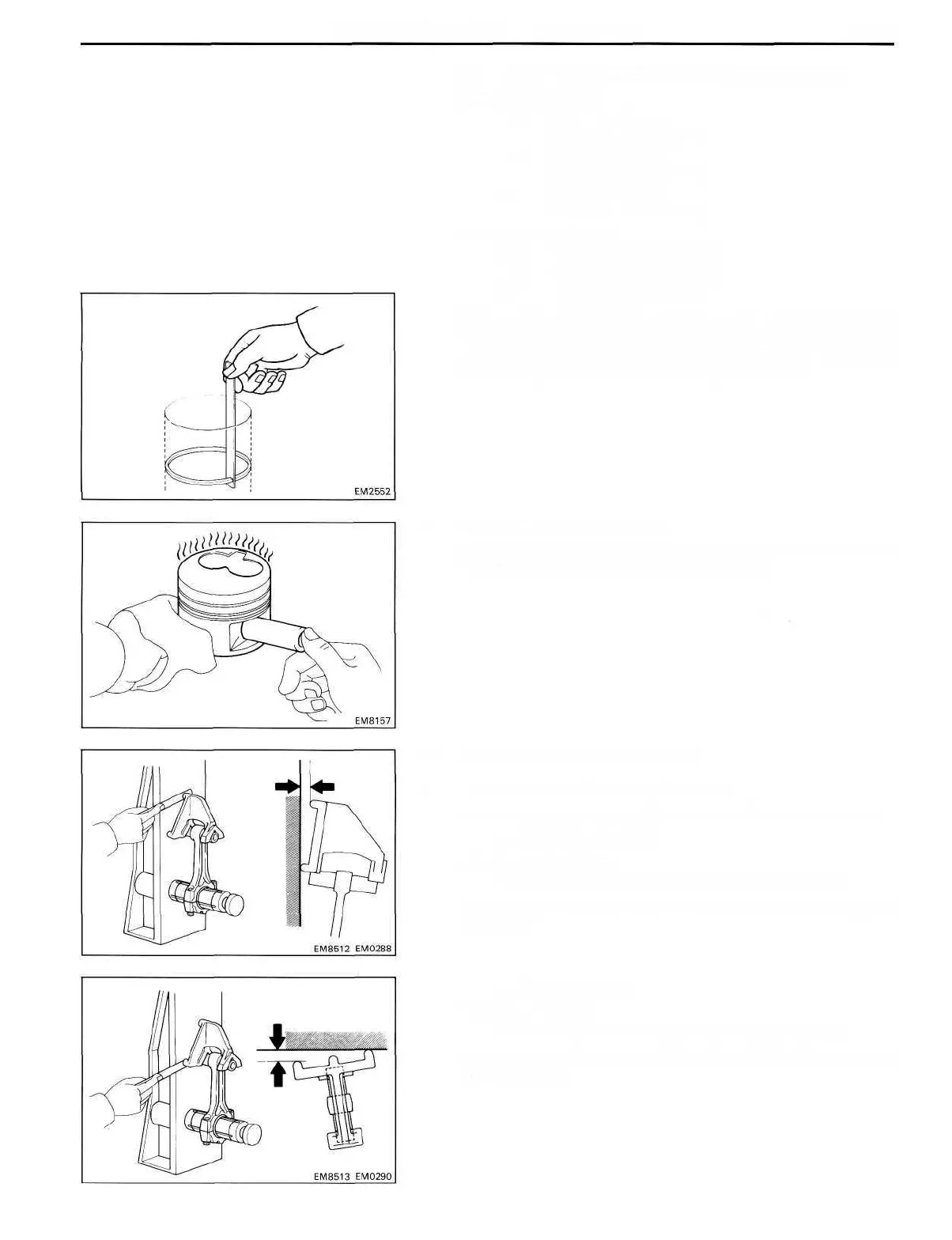

6. INSPECT CONNECTING ROD

A. Inspect connecting rod alignment

Using a rod aligner, check the connecting rod alignment.

• Check for bending.

Maximum bending:

0.03 mm (0.0012 in.) per 100 mm (3.94 in.)

If bent is greater than maximum, replace the connecting rod

assembly.

• Check for twist.

Maximum twist:

0.15 mm (0.0059 in.) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting

rod assembly.

Loading...

Loading...