LU-14 LUBRICATION SYSTEM - Oil Pump

3. INSTALL OIL STRAINER

Install a new gasket and the oil strainer with the two bolts

and two nuts.

Torque: 90 kg-cm (78 in.-lb, 8.8 Nm)

4. INSTALL OIL PAN

(a) Remove any old packing (FIPG) material and be

careful not to drop any oil on the contact surfaces of

the oil pan and cylinder block.

• Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

• Thoroughly clean all components to remove all the

loose material.

• Using a non-residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

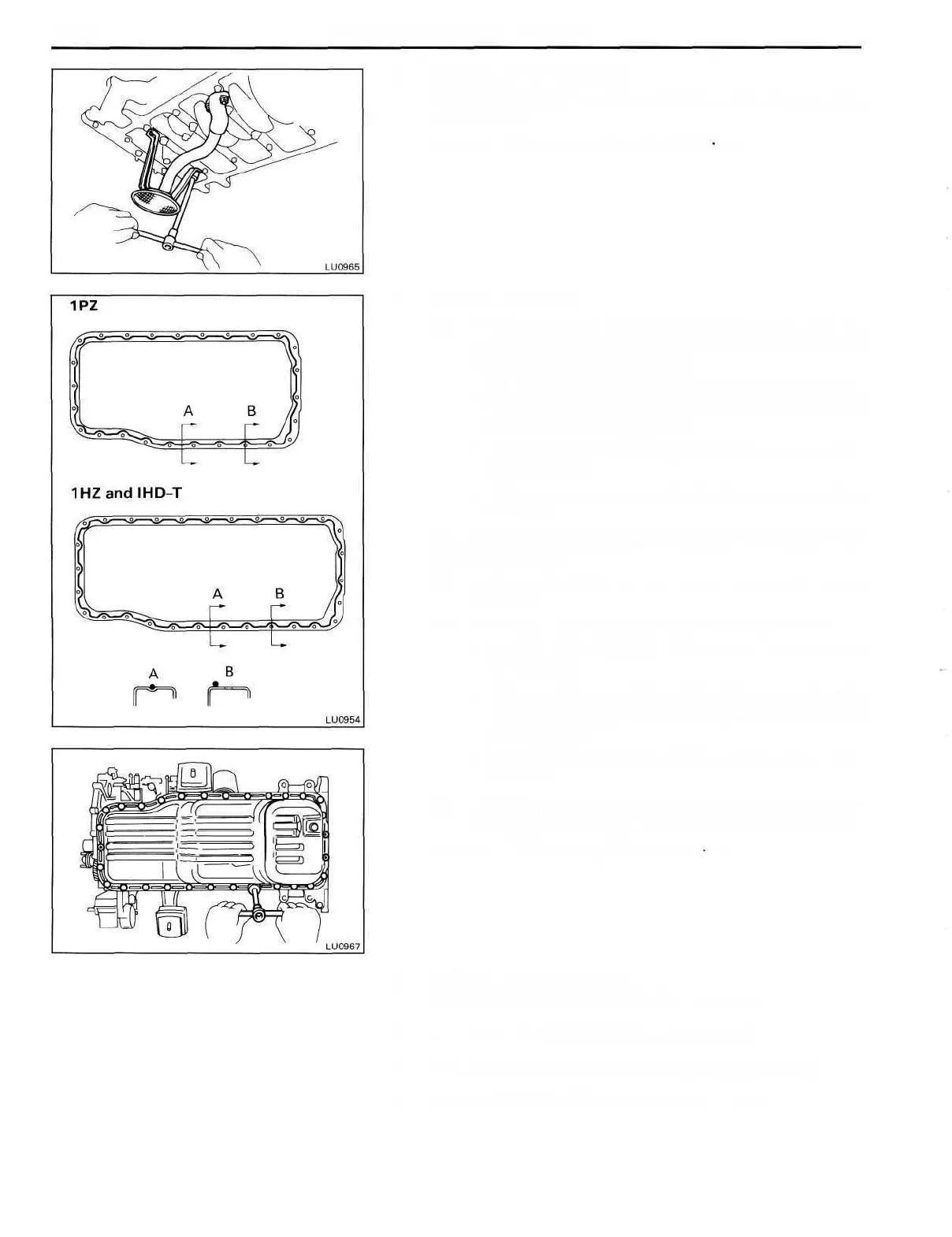

(b) Apply seal packing to the oil pan as shown in the

illustration.

Seal packing: Part No.08826-00080 or equivalent

• Install a nozzle that has been cut to a 5 mm (0.20

in.) opening.

• Parts must be assembled within 5 minutes of appli-

cation. Otherwise the material must be removed

and reapplied. *

• Immediately remove nozzle from the tube and rein-

stall cap.

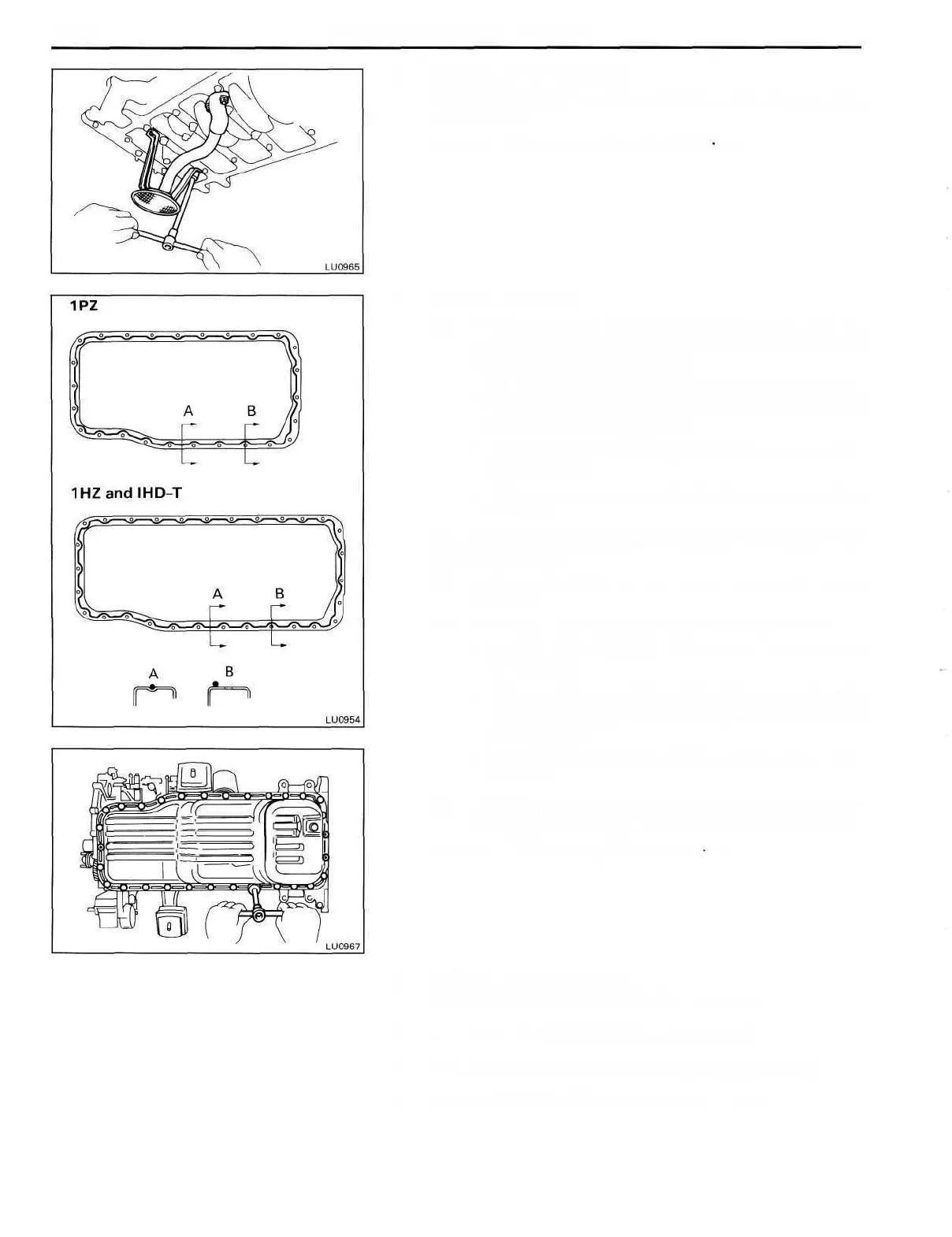

(c) Install the oil pan with the twenty-three bolts (1 PZ) or

twenty-seven bolts (1 HZ and 1 HD-T) and three nuts.

Torque: 100 kg-cm (7 ft-lb, 10 Nm)

5. INSTALL TIMING GEARS

(See steps 2 to 12 on pages EM-50 to 53)

6. FILL WITH ENGINE OIL (See page LU-7)

7. FILL WITH ENGINE COOLANT (See page CO-5)

8. START ENGINE AND CHECK FOR LEAKS

Loading...

Loading...