FUEL SYSTEM - Injection Nozzles (1 HD-T) FU-23

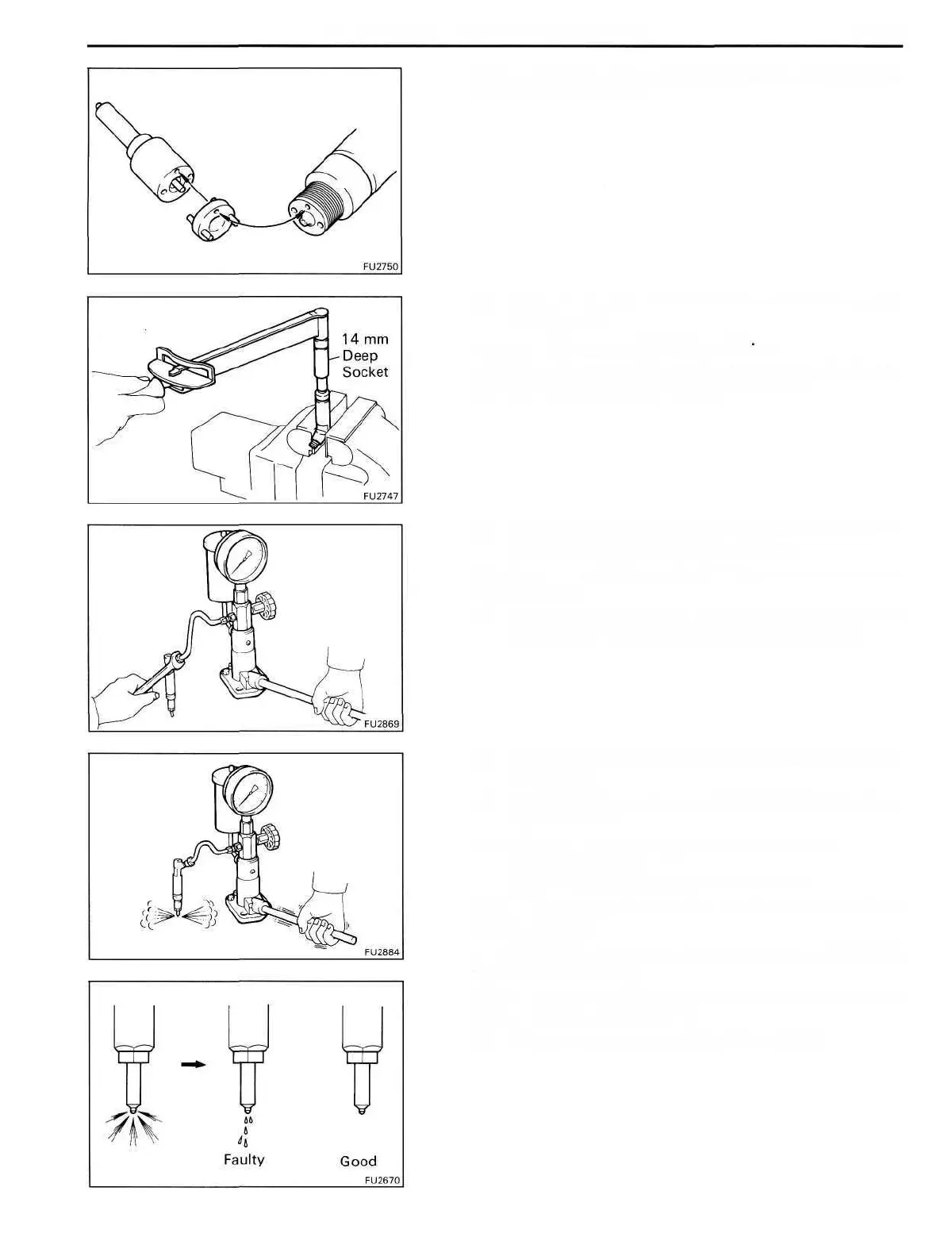

HINT: Align the holes of the nozzle body, distance piece

and nozzle holder body.

(c) Using a 14 mm deep socket wrench, torque the

retaining nut.

Torque: 350 kg-cm (25 ft-lb, 34 N m)

NOTICE: Over torquing could cause nozzle deforma-

tion and needle adhesion or other defects.

(d) Install the injection nozzle to the injection nozzle hand

tester and bleed air from the union nut.

CAUTION: Do not place your finger over the nozzle

injection hole.

(e) Pump the tester handle a few times as fast as possible

to discharge the carbon from the injection hole.

(f) Pump the tester handle slowly and observe the pres-

sure gauge.

(g) Read the pressure gauge just as the injection pressure

begins to drop.

No.2 opening pressure (Inspection pressure):

132-138 kg/cm

2

(1,877-1,963 psi, 12,945-13,533 kPa)

HINT: Proper nozzle operation can be determined by a

swishing sound.

If the opening pressure is not as specified, replace the

capsule sub-assembly.

HINT: The No.2 opening pressure is already adjusted for

the new capsule sub-assembly.

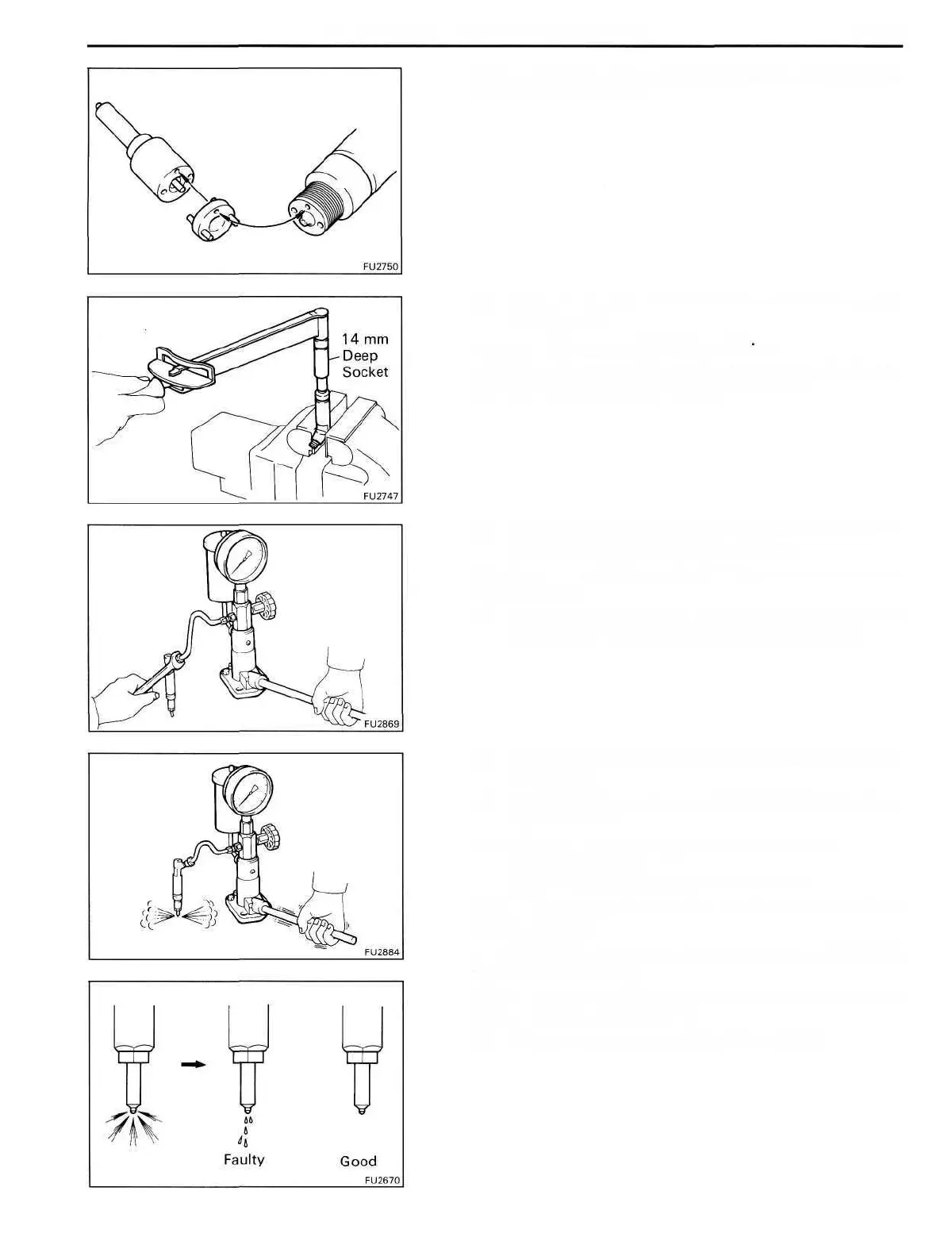

(h) There should be no dripping after injection.

Loading...

Loading...