EM-87

ENGINE MECHANICAL Cylinder Block

(d) Clean crank pin and bearing.

(e) Check the crank pin and bearing for pitting and

scratches.

If the crank pin or bearing is damaged, replace the bearings.

If necessary, grind or replace the crankshaft.

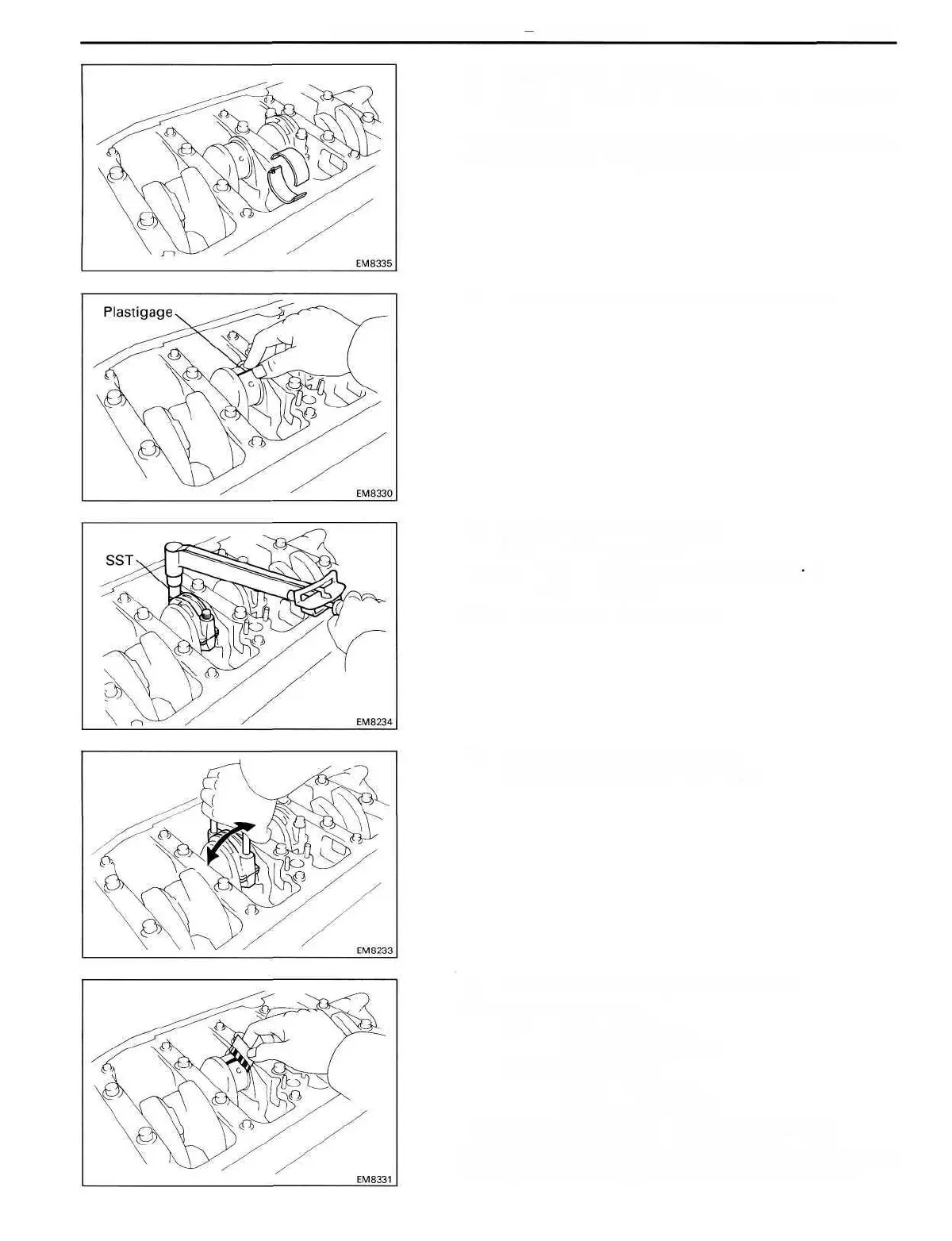

(f) Lay a strip of Plastigage across the crank pin.

(g) Install the connecting rod cap.

(See step 8 on page EM-111)

Torque: 1st 375 kg-cm (27 ft-lb, 37 Nm)

2nd turn 90°

HINT: Do not turn the crankshaft.

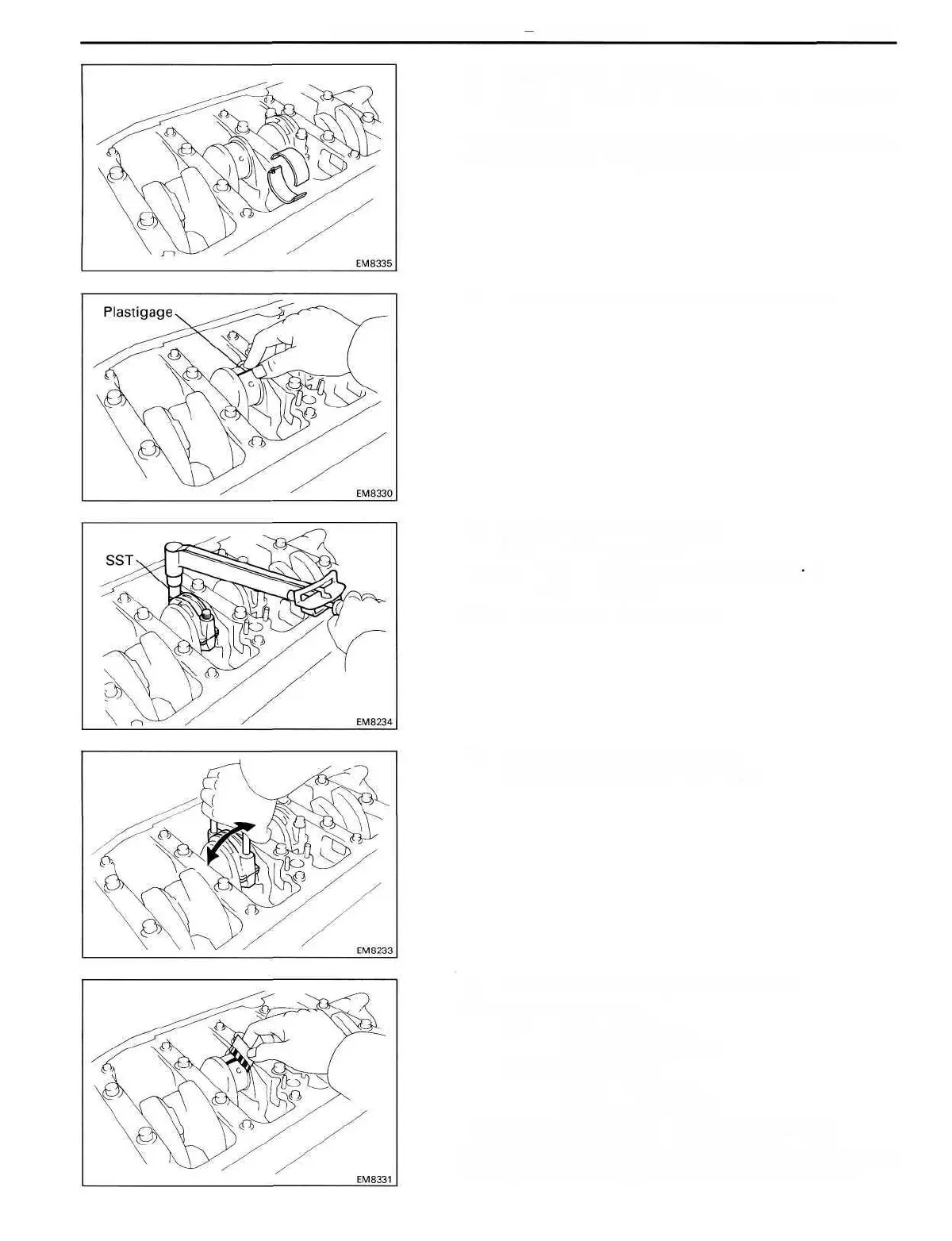

(h) Remove the connecting rod cap.

(See procedure (b) and (c) above)

(i) Measure the Plastigage at widest point.

Standard oil clearance:

STD 0.036-0.054 mm

(0.0014-0.0021 in.)

U/S 0.25 and U/S 0.50

0.037 - 0.077 mm

(0.0015 - 0.0030 in.)

Maximum oil clearance: 0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace the

bearings. If necessary, grind or replace the crankshaft.

Loading...

Loading...