6-8

n

Whirlpool 2014 CABRIO

®

Direct Drive Washer

TESTING

For Service Technician Use Only

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

TEST #3 Drive System

Pre-Test Procedure

1. Acvate Service Diagnosc Test Mode, retrieve any fault/

error codes, and clear them. If the displayed error codes

are F7E3, F7E4, F7E5, F7E6, F7E7, there is likely a motor or

shier related issue.

2. Once the error codes are cleared, enter Service Load

Control Mode and run the Heavy Agitaon test; if the

motor runs aer 15–20 seconds, there is not a problem

with the motor, control, or motor wiring harness

connecons.

3. While in Service Load Control Mode, try to get the washer

to spin; if the motor hums briey and then shuts down, go

to Fault Code Display Mode and check for fault codes.

TEST #3a: Drive System – Shier

This test checks connecons, shier coil, and harness.

NOTE: Lid must be closed and locked for the motor to agitate

or spin.

IMPORTANT: Drain water from tub before accessing boom of

washer.

Functional Check:

1. Check the shier and electrical connecons by performing

both the Spin and Agitate tests under Service Load Control

Mode on page 5-5. The following steps assume that this

step was unsuccessful.

2. Unplug washer or disconnect power.

3. The motor and shier should be able to be turned

independently of each other. If they are locked together,

there is a shier slider issue. Proceed to step 12.

NOTE: Rotang the impeller quickly can cause the UI to

aempt to power up, and may cause audible feedback

and the main control to power up and apply braking

torque to the impeller.

¾ If basket and impeller turn freely, go to step 4.

¾ If basket and/or impeller do not turn freely, determine

what is causing the mechanical fricon or lockup.

4. Remove console to access main control.

5. Visually check that the J4 connector is inserted all the way

into the main control.

¾ If visual checks pass, go to step 6.

¾ If connector is not inserted properly, reconnect J4 and

repeat step 1.

6. With a voltmeter set to AC, connect the black probe to

J4-1 (N) and red probe to J4-7 (L1). Plug in washer or

reconnect power.

7. Acvate shier motor by switching the shier output

ON and OFF. Energize outputs using Service Load Control

Mode on page 5-5.

NOTE: Motor must be stopped to toggle the shier.

Alternately, Spin and Agitate can be commanded to switch

shier in Service Load Control Mode.

IMPORTANT: Lid must be closed with Lid Lock enabled to

run the Spin and Agitate tests.

¾ If 120VAC is present, go to step 8.

¾ If 120VAC is not present, go to step 12.

8. Unplug washer or disconnect power.

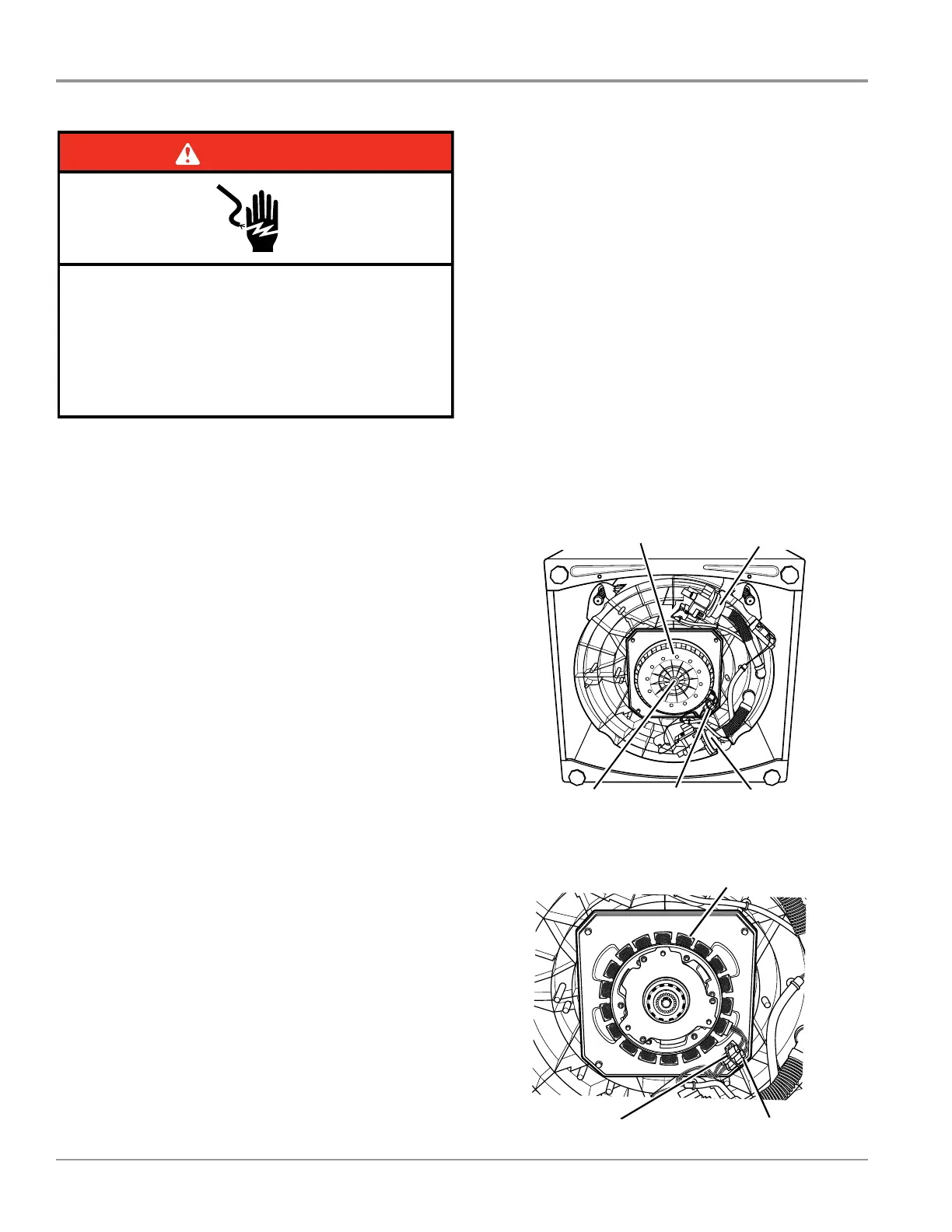

9. Tilt washer back and remove sound pad (if equipped) to

access the drive system (see Figure 1).

3$*(

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

¾ If 120VAC is present, go to step 8.

¾ If 120VAC is not present, go to step 12.

8. Unplug washer or disconnect power.

9. Tilt washer back and remove sound pad

(if equipped) to access the drive system (see

Figure 3a).

10. Visually check the electrical connections

to the shifter.

¾ If visual check passes, go to step 11.

¾ If connections are loose, reconnect the

electrical connections and repeat step 1.

11. With an ohmmeter, check the harness for

continuity between the shifter and main control

using the following pinouts. See chart below.

¾ If there is continuity, go to step 12.

¾ If there is no continuity, replace the lower

washer harness and repeat step 1.

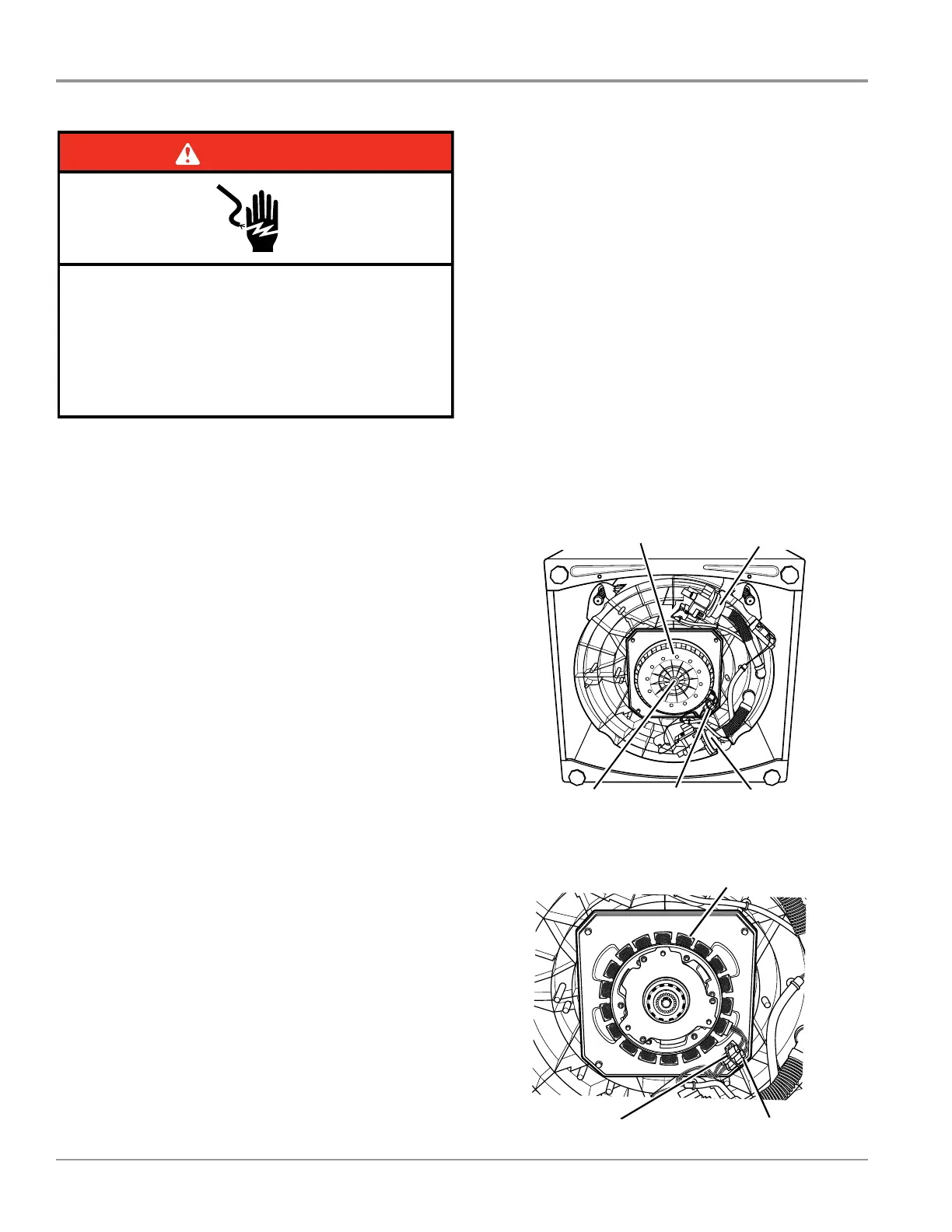

12. Remove the motor bolt, then the motor

cover (see Figure 3b). Remove the motor stator

and the shifter coil and confirm that the slider

on the motor shaft moves freely (see Figure 4).

¾ If slider moves freely, and there are no

indications of rubbing on the inside diameter

of the shifter coil and outside diameter of the

slider, go to step 13.

¾ If slider binds or does not move freely, or

there are indications of rubbing on the inside

diameter of the shifter coil or outside diameter

of the slider, replace the drive.

a. Unplug washer or disconnect power.

b. Replace the drive.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power.

Perform Service Diagnostics to verify repair.

13. If the preceding steps did not correct the

problem, replace the main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power.

Perform Service Diagnostics to verify repair.

TEST #3b: Drive System – Motor

This test checks the wiring to the motor and

the motor itself.

NOTE: Drain water from tub and remove any

wash load items present in the basket.

1. See Activating Service Diagnostic Mode,

page 2, and check the motor and electrical

connections by performing the Low, Mid, and

High Speed Spin Test under Service Load

Control Mode, page 4. The following steps

assume that this step failed.

2. Unplug washer or disconnect power.

3. Check to see if impeller will turn freely and

is not connected to the basket.

NOTE: Rotating the impeller quickly can cause

the UI to attempt to power up, and may cause

audible feedback and the main control to power

up and apply braking torque to the impeller.

¾ If impeller turns freely, go to step 4.

¾ If impeller does not turn freely, determine

what is causing the mechanical friction or

lockup.

Shifter and Pump Connector Harness

J4-1 (White wire)

J4-7 (Orange wire)

To shifter connector Pin 3 (White wire)

To shifter connector Pin 1 (Orange wire)

Figure 3a - Drive Area, Viewed From Bottom,

Sound Pad (If Equipped) Removed

Figure 3b - Motor Cover Removed

Figure 4 - Checking Slider Movement/Appearance

Motor Cover

Motor Bolt

Recirculation Pump

Drain Pump

Motor/Shifter

Connector

Stator

Motor ConnectionShifter Connection

Figure 1 - Drive Area, Viewed From Bottom,

Sound Pad (if equipped) Removed

3$*(

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

¾ If 120VAC is present, go to step 8.

¾ If 120VAC is not present, go to step 12.

8. Unplug washer or disconnect power.

9. Tilt washer back and remove sound pad

(if equipped) to access the drive system (see

Figure 3a).

10. Visually check the electrical connections

to the shifter.

¾ If visual check passes, go to step 11.

¾ If connections are loose, reconnect the

electrical connections and repeat step 1.

11. With an ohmmeter, check the harness for

continuity between the shifter and main control

using the following pinouts. See chart below.

¾ If there is continuity, go to step 12.

¾ If there is no continuity, replace the lower

washer harness and repeat step 1.

12. Remove the motor bolt, then the motor

cover (see Figure 3b). Remove the motor stator

and the shifter coil and confirm that the slider

on the motor shaft moves freely (see Figure 4).

¾ If slider moves freely, and there are no

indications of rubbing on the inside diameter

of the shifter coil and outside diameter of the

slider, go to step 13.

¾ If slider binds or does not move freely, or

there are indications of rubbing on the inside

diameter of the shifter coil or outside diameter

of the slider, replace the drive.

a. Unplug washer or disconnect power.

b. Replace the drive.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power.

Perform Service Diagnostics to verify repair.

13. If the preceding steps did not correct the

problem, replace the main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power.

Perform Service Diagnostics to verify repair.

TEST #3b: Drive System – Motor

This test checks the wiring to the motor and

the motor itself.

NOTE: Drain water from tub and remove any

wash load items present in the basket.

1. See Activating Service Diagnostic Mode,

page 2, and check the motor and electrical

connections by performing the Low, Mid, and

High Speed Spin Test under Service Load

Control Mode, page 4. The following steps

assume that this step failed.

2. Unplug washer or disconnect power.

3. Check to see if impeller will turn freely and

is not connected to the basket.

NOTE: Rotating the impeller quickly can cause

the UI to attempt to power up, and may cause

audible feedback and the main control to power

up and apply braking torque to the impeller.

¾ If impeller turns freely, go to step 4.

¾ If impeller does not turn freely, determine

what is causing the mechanical friction or

lockup.

Shifter and Pump Connector Harness

J4-1 (White wire)

J4-7 (Orange wire)

To shifter connector Pin 3 (White wire)

To shifter connector Pin 1 (Orange wire)

Figure 3a - Drive Area, Viewed From Bottom,

Sound Pad (If Equipped) Removed

Figure 3b - Motor Cover Removed

Figure 4 - Checking Slider Movement/Appearance

Motor Cover

Motor Bolt

Recirculation Pump

Drain Pump

Motor/Shifter

Connector

Stator

Motor ConnectionShifter Connection

Figure 2 - Motor Cover (Rotor) Removed

Recirculaon Pump

Motor Bolt Motor/Shier

Connector

Motor Cover

Drain Pump

Stator

Shier Connecon Motor Connecon

Loading...

Loading...