TESTING

Whirlpool 2014 CABRIO

®

Direct Drive Washer

n

6-15

For Service Technician Use Only

TEST #8: Lid Lock

Perform the following checks if the washer does not lock (or

unlock).

1. Check the lid lock by performing Lid Lock test under

Service Load Control Mode in Service Diagnosc Mode on

page 5-5. The following steps assume that this step was

unsuccessful.

2. Unplug washer or disconnect power.

3. Remove console to access main control.

4. Visually check that the J6 connector is inserted all the way

into the main control.

¾ If visual check passes, go to step 5.

¾ If connector is not inserted properly, reconnect J6 and

repeat step 1.

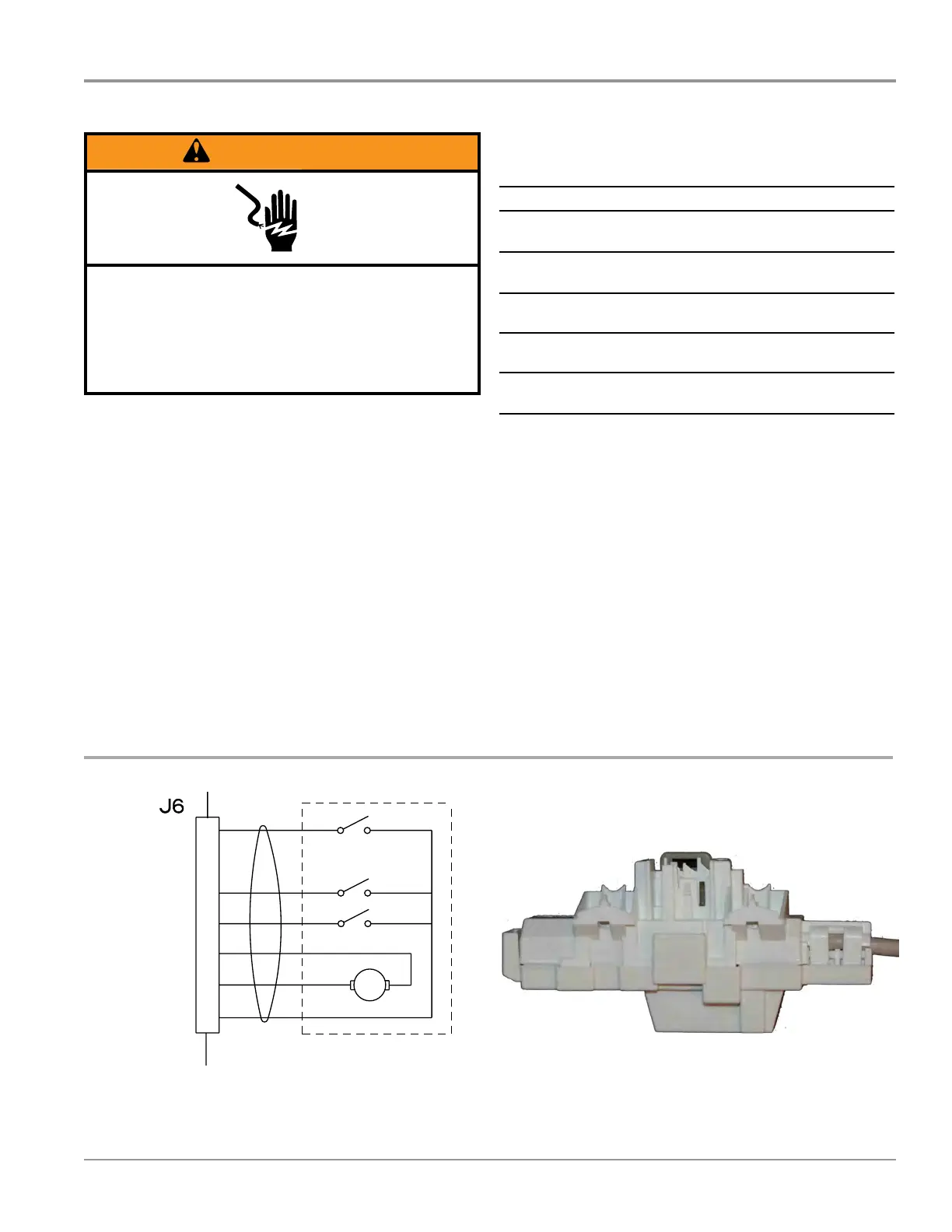

5. Check the lid lock motor winding and switches by

removing J6 from the main control and checking the

resistance values shown in the following table:

LID LOCK RESISTANCE

Component

Resistance

Unlocked

Resistance

Locked

Contacts

Motor

Winding

35 W

(±5 W)

35 W

(±5 W)

J6-2 J6-3

Lock Switch-

Home

0 W

Open

Circuit

J6-1 J6-4

Lock Switch-

Lock

Open

Circuit

0 W J6-1 J6-7

Lock Switch-

Lid

Lid Closed = 0 W

Lid Open = Open Circuit

J6-1 J6-5

¾ If resistance values are good, go to step 6.

¾ If switch measurements do not match the values

shown in the table for unlocked (or locked) condion,

a problem exists in the lid lock. Replace the lid lock

mechanism.

6. If the preceding steps did not correct the lock problem,

replace the main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Perform Service

Diagnoscs to verify repair.

3$*(

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

Wiring Diagram

IMPORTANT: Electrostatic discharge may cause damage to machine control electronics. See page 1 for

ESD information.

NOTE: Schematic shows lock switch open.

Figure 8 - Wiring Diagram

RECIRC.

PUMP

DRAIN

PUMP

NOT ON ALL MODELS

120 VAC PUMPS

& SHIFTER

SHIFTER

COIL

W

OR

W

LBU W

7 5 3 1

4 3 1 6

3 PHASE

BPM MOTOR

4 3 2 1

BK BR R

VS3

VS1

VS2

BPM MOTOR

DRIVE

NOT ON ALL MODELS

HEATER

ELEMENT

1 2

BK GY

1

2

3

BK

G

W

G

L1

G

N

120 VAC

POWER

CORD

AA BB

MOTOR

PLATE

CABINET

G/Y

RTN (VSS)

VALVE

THERMISTOR

SOFTENER

BLEACH/OXI

MAIN HOT

MAIN COLD

THERMISTOR

BK

BK

T

W

OR

V

R

BU

1

2

3

4

5

6

7

8

9

10

11

12

WATER INLET VALVE

120 VAC

GROUND CIRCUIT

5V

WIDE

RTN (VSS)

1 2 3

SMART UI

SPEAKER

BK BU Y

LOCK SW

LID SW

HOME SW

LOCK MOTOR

LOCK MOTOR

SW OUT

1

2

3

4

5

6

7

W

R

BK

BU

BR

G

GRAY

JACKET

DC LOCK

LOCK

LID

HOME

12 VDC MOTOR

1

3

1

3

1

3

1

3

1 3

BU

(NOT ON

ALL MODELS)

FULL WAVE

BRIDGE

RECTIFIER

NEUT

L1 N

L1

G

N

RECIRC.

NEU

DRAIN

PUMP

ON BOARD

PRESSURE

TRANSDUCER

PRESSURE

HOSE TO TUB

SHIFTER

HF RETURN

Figure 1 - Lid Lock Schematic Figure 2 - Lid Lock

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Failure to do so can result in death or

electrical shock.

Replace all parts and panels before operating.

Loading...

Loading...