16 Detecting anomalies

121

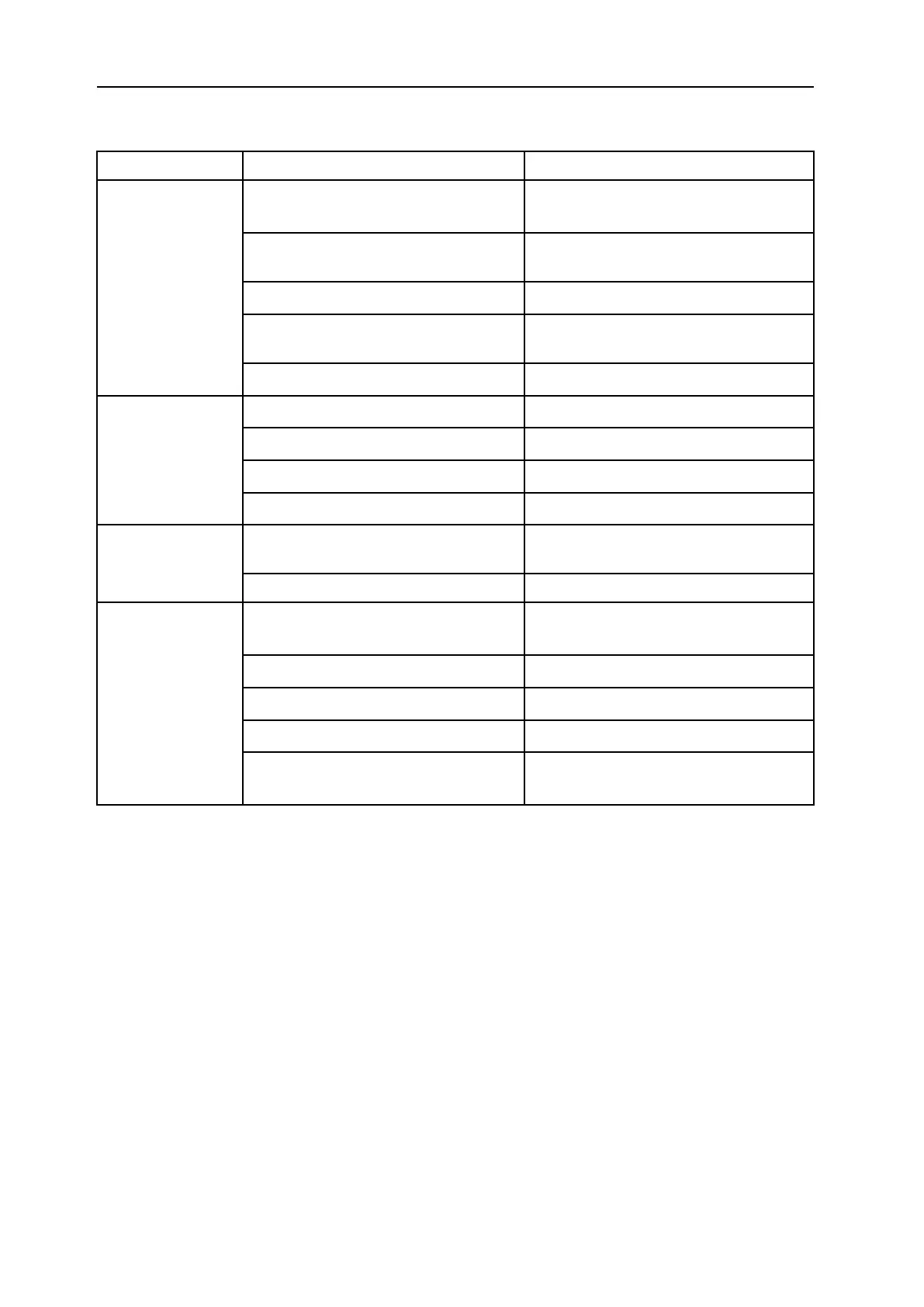

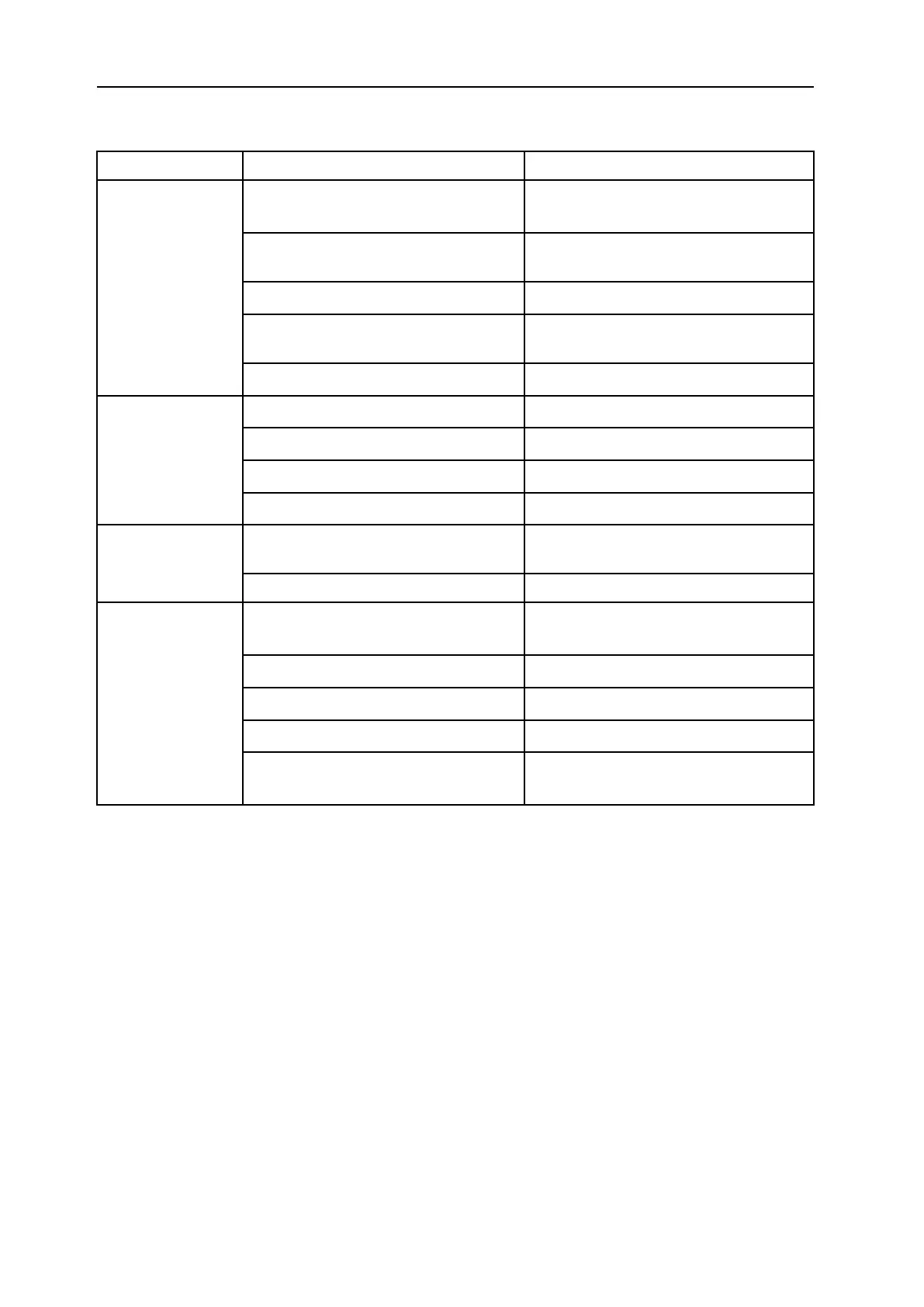

16.2.3 Machine structure

Problem Cause Solution

The power or

speed of the

moving parts is

low.

Lack of pressure due to wear on the

hydraulic pump.

(Replace the hydraulic pump).

Pressure drop in the distributor be-

low the set value.

(Check and repair the valves).

Damaged hydraulic cylinder. (Check and repair).

Insufficient quantity of hydraulic

oil.

Fill the hydraulic oil to the required

level.

Clogged filter. Clean or replace the filter.

The upper part

does not rotate or

does not rotate

smoothly.

The rotation brake is not unlocked.

Unlock the rotation locking lever.

Insufficient quantity of grease.

Check and lubricate.

Defective rotation brake valve.

(Check and repair).

Defective rotation motor.

(Check and repair).

The hydraulic oil

temperature is

too high.

Insufficient quantity of hydraulic

oil.

Fill the hydraulic oil to the required

level.

Overload Reduce the load.

The machine

does not move

forward in a

straight line.

Track incorrectly tightened or fo-

reign body jammed.

Adjust or clean.

Damaged hydraulic motor. (Check and repair).

Defective hydraulic pump. (Check and repair).

Defective safety valve. (Check and repair).

Sprocket, tightening roller or trac-

ker roller damaged.

(Check and repair).

Loading...

Loading...