6 Maintenance by the operator

148

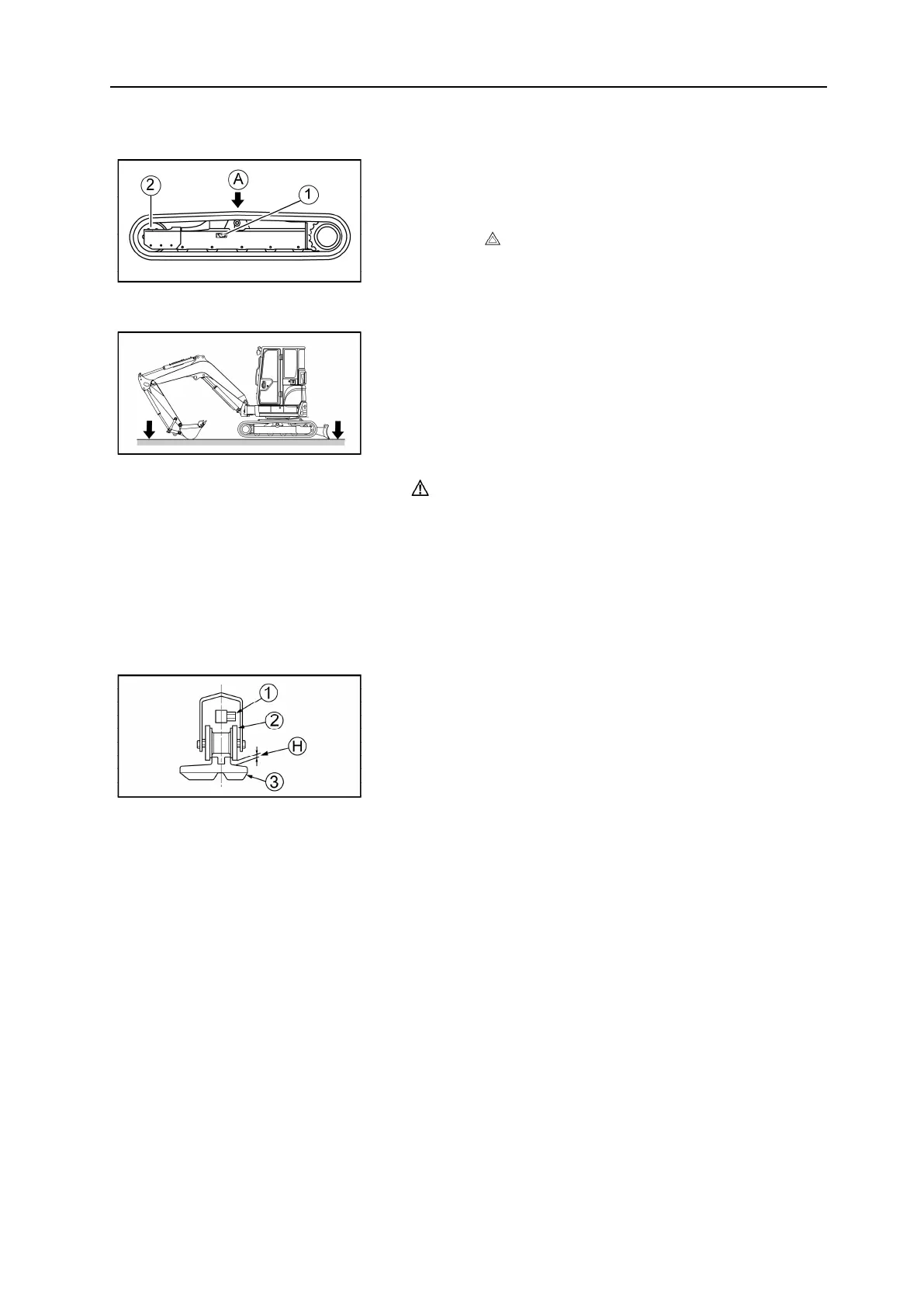

6.5.3 Tension check

1. Move the machine so that the seal on the internal sur-

face of the track is placed in the centre of the upper

chassis.

A = Mark

inside the track

1 = Cover

2 = Idle wheel

2. Raise the machine with the equipment by activating

the command lever.

WARNING

Do not support the machine with the accessory only. The command levers may move or hy-

draulic oil may spill accidentally and cause the machine to fall.

When the machine is checked or adjusted by two people, one of them must commission the

machine according to the signals given by the other person.

Be sure to perform the track tension verification on a firm and even surface. It is strictly

forbidden to be positioned under the machine for the duration of the operation.

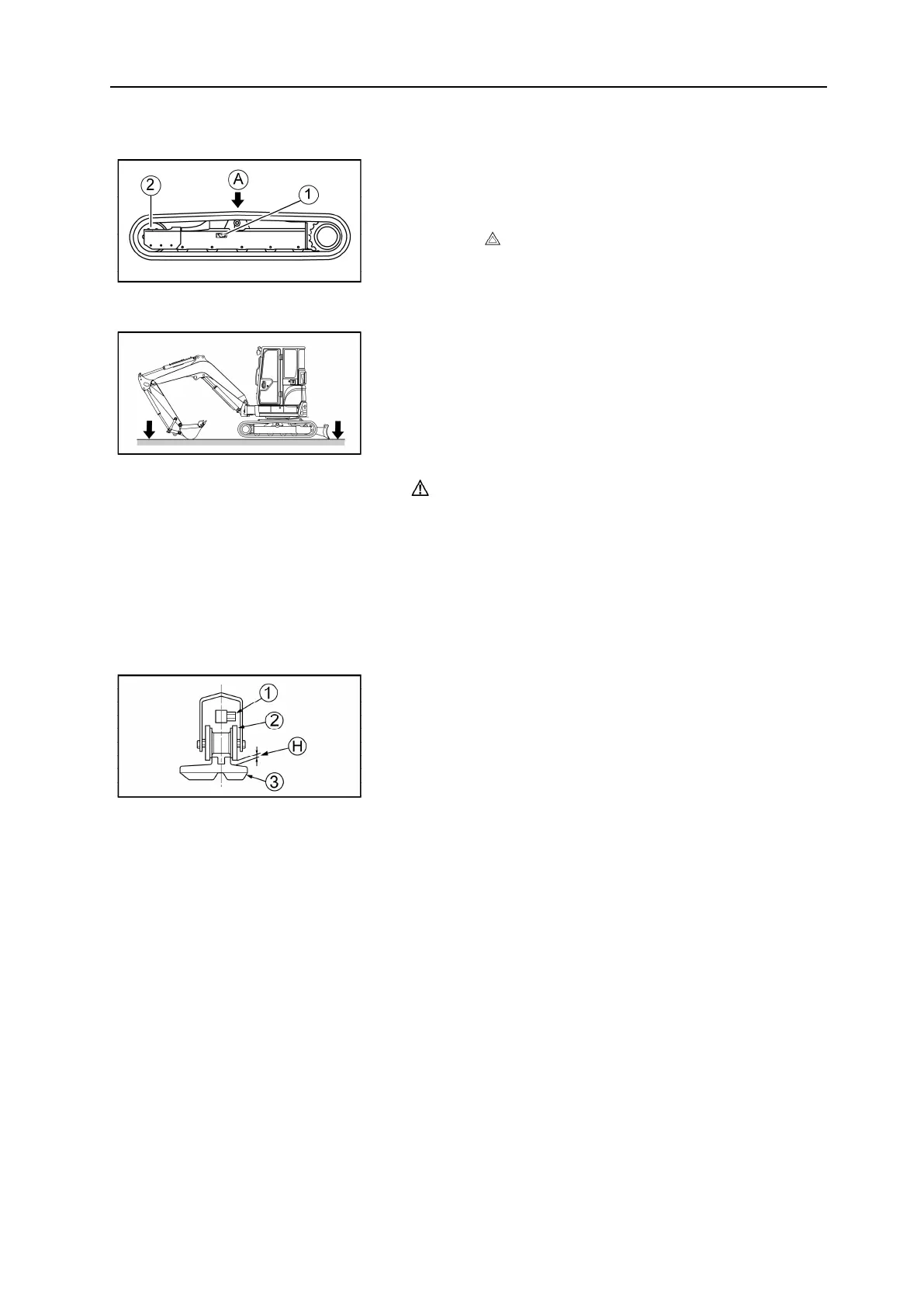

3. Check the tension. The play H between the external

rolling surface of the second track roller on the tightener

roller and the internal surface of the track must be

8 ~ 13 mm.

1 = Greaser

2 = Track roller

3 = Track

• If the tension is incorrect, follow the procedures given in the following chapters to increase

or release the track tension.

IMPORTANT

Perform a task with a relaxed track link may derail the track or cause premature wear of

the undercarriage.

Loading...

Loading...