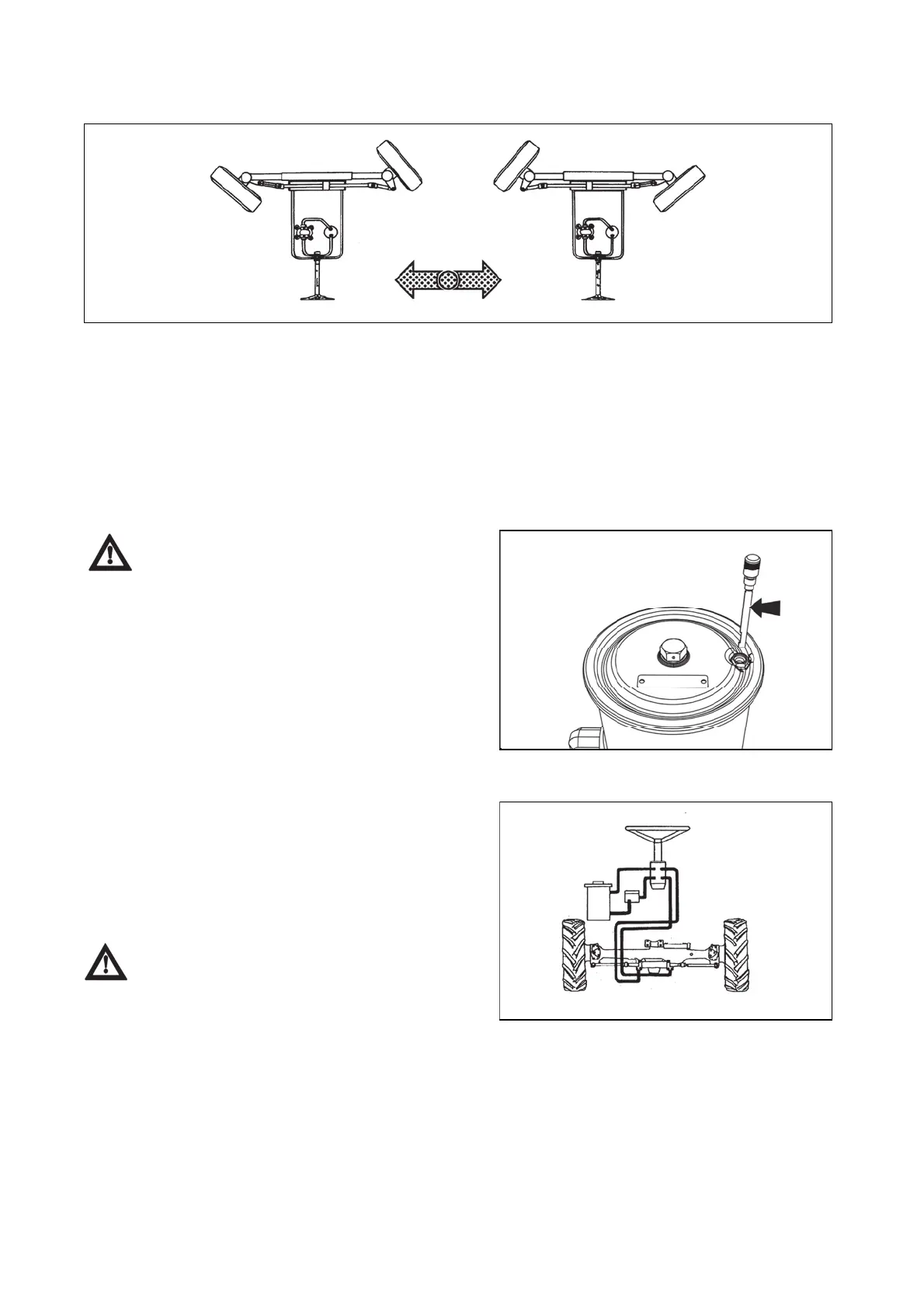

enting hydraulic circuit of hydrostatic steerin

E722

1. secure the tractor against movement and lift the front axle

2. start the engine and allow it to run for approximately 1 minute in idle run

3. turn the steering wheel several times to both sides with idle run

4. with maximum engine revolutions, turn the steering wheel 3 times alternately slowly and quickly to both

sides to restricting wheel stop

5. stop the engine

6. after completing the venting check or replenish the oil level to control gauge line. Check the tightness of all

oints and hydraulic circuit guide-ways of hydrostatic steering

7. lower the tractor down to front wheels

Replacing the hoses of hydrostatic steering

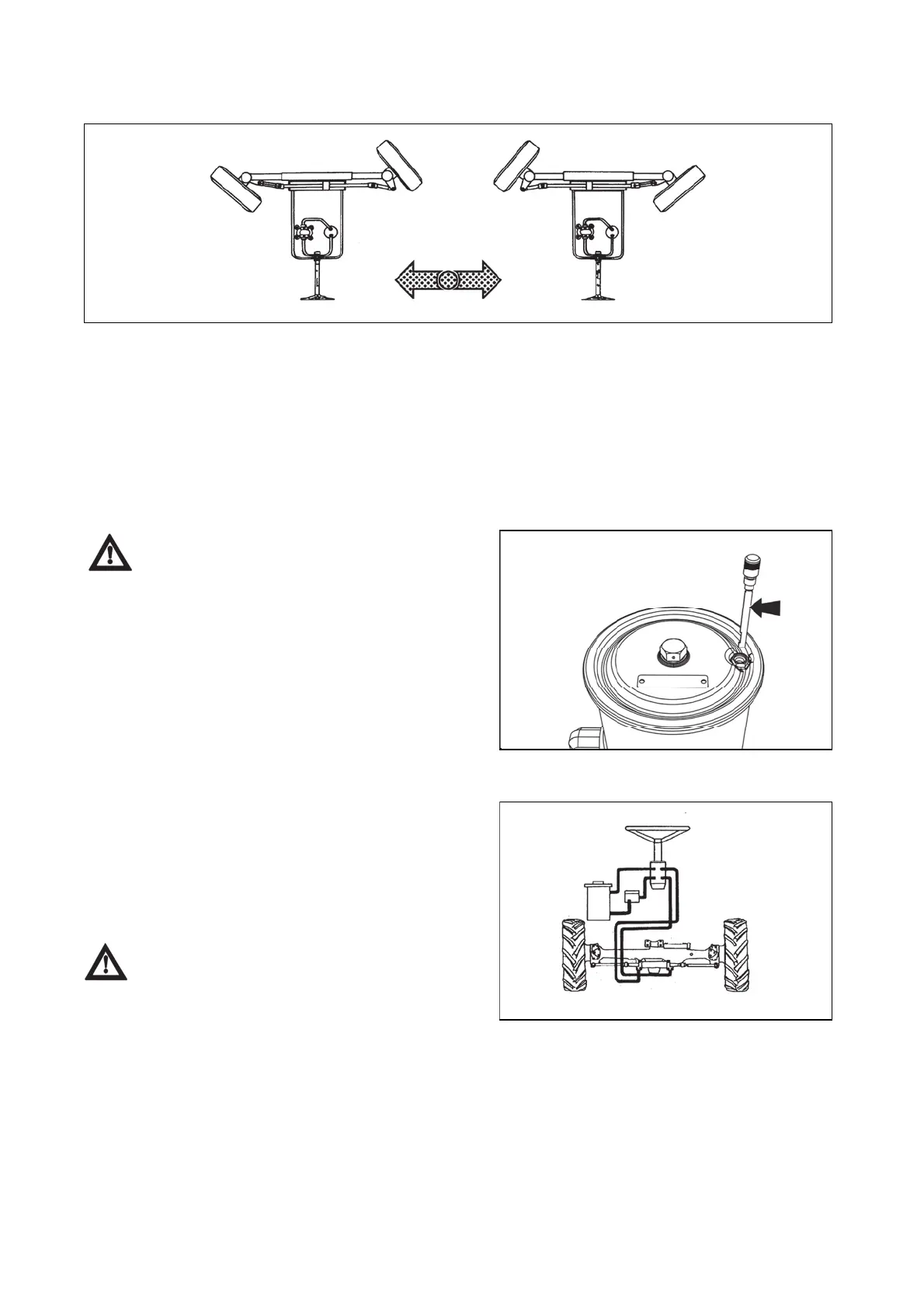

Monitor oil level in the tank with all hydrostatic

steering venting steps to prevent air sucking to the

system of steering.

PGPPN147

Hoses need to be replaced four years from the date of

their manufacture (date is given on their surface) or after

working 3,500 hours with tractor, or right after learning the

symptoms of their damage (hose, local swelling,

penetration of working medium around endpoints and

hose surface, wrapping damage by mechanical smear to

a metallic body, damage to external buckle braid with low-

pressure hoses).

If a pump gets damaged or if the engine is at

standstill, steerability is observed, but the force on

the steering wheel increases. It is possible to get to

the nearest place where repairs can be done with

lowered speed. The steering wheel must not be held

in the positions of extreme wheel locks for longn

(maximum time is 20 sec.), otherwise there is

excessive oil heating in hydrostatic steering circuit.

G719

Loading...

Loading...